This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins Oil Suction Connection, part number 4308111, is a critical component designed to facilitate the efficient operation of commercial trucks. This part is integral to the engine lubrication system, ensuring that oil is properly circulated to critical engine components. Its role in maintaining engine performance and longevity underscores its significance in the operation of commercial vehicles.

Basic Concepts of Oil Suction Connection

An Oil Suction Connection is a component within the engine lubrication system responsible for drawing oil from the oil pan and directing it to the engine’s oil pump. This process ensures a continuous supply of oil is available for lubrication, cooling, and cleaning of engine parts. The connection operates by creating a pathway for oil to flow from the sump to the pump, which then distributes the oil throughout the engine 1.

Purpose of the 4308111 Oil Suction Connection

The 4308111 Oil Suction Connection plays a role in the lubrication system by ensuring a steady flow of oil is maintained. This part is designed to connect the oil pan to the oil pump, facilitating the suction of oil and its subsequent circulation through the engine. Proper lubrication is vital for reducing friction between moving parts, which in turn helps in maintaining engine performance and extending the engine’s operational life 2.

Key Features

The 4308111 Oil Suction Connection is characterized by several design elements and materials that enhance its performance and reliability. It is constructed from durable materials to withstand the high temperatures and pressures within the engine compartment. The design includes precise fittings and connections to ensure a secure and leak-free attachment to the oil pan and pump. Additionally, the part may feature anti-corrosion coatings to protect against the harsh environments often encountered in commercial truck operations.

Benefits

The use of the 4308111 Oil Suction Connection offers several benefits. It contributes to improved engine lubrication by ensuring a consistent oil flow, which is crucial for the protection of engine components. The part’s durable construction and reliable design enhance the engine’s durability and may contribute to fuel efficiency by maintaining optimal lubrication conditions. Furthermore, the reliable performance of this connection can lead to reduced maintenance costs by minimizing the risk of oil leaks and related issues.

Installation and Compatibility

Proper installation of the 4308111 Oil Suction Connection is crucial for its effective operation. The installation process may require specific tools and techniques to ensure a secure and leak-free connection. It is compatible with various Cummins engine models, making it a versatile component for fleet maintenance and upgrades. Detailed installation instructions should be followed to ensure compatibility and optimal performance.

Troubleshooting and Maintenance

Common issues with the 4308111 Oil Suction Connection may include leaks or blockages, which can affect oil flow and engine lubrication. Troubleshooting steps may involve inspecting the connection for signs of wear or damage, ensuring all fittings are secure, and checking for any obstructions in the oil pathway. Regular maintenance practices, such as cleaning and inspecting the connection during routine oil changes, can help ensure its longevity and performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations. The 4308111 Oil Suction Connection is a testament to Cummins’ commitment to providing high-quality, reliable components for the maintenance and operation of commercial trucks.

Cummins Engine Part 4308111: Oil Suction Connection

The Cummins part number 4308111, identified as an Oil Suction Connection, is a critical component in the lubrication system of several Cummins engines. This part ensures that oil is effectively drawn from the oil pan and supplied to the engine’s lubrication system, which is essential for maintaining engine health and performance.

VTA903 and CM2250 Engines

The Oil Suction Connection part 4308111 is integral to the VTA903 and CM2250 engines. These engines, known for their robust design and reliability, require precise lubrication to function optimally. The oil suction connection facilitates the smooth flow of oil, ensuring that all moving parts are adequately lubricated, which helps in reducing friction and wear, and ultimately extends the engine’s lifespan.

V105 Engine

Similarly, the V105 engine also utilizes the Oil Suction Connection part 4308111. This engine is designed for heavy-duty applications, and the efficient operation of its lubrication system is paramount. The oil suction connection in this engine ensures that the oil is drawn efficiently from the oil pan and distributed throughout the engine, maintaining the necessary lubrication levels to handle the demanding conditions of its intended use.

Grouping of Engines

The VTA903 and CM2250 engines, while distinct in their specific applications and configurations, share a commonality in their requirement for the Oil Suction Connection part 4308111. This part’s role in these engines is to maintain the integrity of the lubrication system, ensuring that oil is consistently and effectively circulated. The V105 engine, on the other hand, also relies on this part to manage the high demands of its heavy-duty operations, highlighting the universal importance of the Oil Suction Connection in Cummins engines.

Role of Part 4308111 Oil Suction Connection in Engine Systems

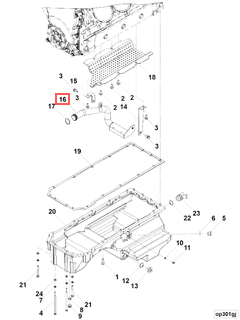

The part 4308111 Oil Suction Connection is an essential component in the lubrication system of an engine, facilitating the efficient circulation of oil. This component is strategically positioned to interface with the oil pan, which serves as the reservoir for the engine oil.

Interaction with the Oil Pan

The Oil Suction Connection is designed to connect to the oil pan, allowing it to draw oil from the pan’s sump. This connection ensures a consistent supply of oil is available for the engine’s lubrication system. The design of the connection point is typically threaded or flanged to create a secure seal, preventing any oil leaks that could lead to a loss of lubrication and potential engine damage.

Oil Circulation Process

Once the Oil Suction Connection has drawn oil from the pan, it directs the oil towards the oil pump. The pump then pressurizes the oil and distributes it throughout the engine’s moving parts. This process is vital for reducing friction, dissipating heat, and removing contaminants from the engine’s internal components 3.

Maintenance and Efficiency

Regular maintenance of the Oil Suction Connection is important to ensure the longevity and efficiency of the engine’s lubrication system. Any blockages or leaks in this component can lead to inadequate oil supply, which may result in increased wear on engine parts and reduced performance. Engineers and mechanics should inspect this connection during routine maintenance checks to ensure it is functioning correctly and is free from debris or corrosion.

Conclusion

In summary, the 4308111 Oil Suction Connection plays a significant role in the engine’s lubrication system by ensuring a reliable flow of oil from the oil pan to the pump, which is essential for the engine’s operation and durability. Its design and construction are tailored to withstand the demanding conditions of commercial truck operations, contributing to the overall efficiency and longevity of the engine.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Drozdziel, P. (2023). The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.