4066368

Lubricating Oil Supply Tube

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

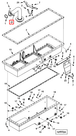

The Lubricating Oil Supply Tube, identified by Part #4066368, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This tube is integral to the lubrication system of heavy-duty truck engines, facilitating the delivery of oil to various critical components within the engine.

Function and Operation

The Lubricating Oil Supply Tube operates as a conduit within the engine’s lubrication system. Its primary role is to deliver oil from the oil pump to essential engine components, ensuring they receive the necessary lubrication for smooth operation. By maintaining a consistent flow of oil, it helps in reducing friction between moving parts, which is vital for the engine’s efficiency and longevity 1.

Key Features

The design and construction of the Lubricating Oil Supply Tube are tailored for durability and efficiency. It is typically made from high-quality materials that can withstand the high pressures and temperatures within an engine environment. The tube features secure connection types, ensuring a reliable seal that prevents oil leaks. Additionally, its design may include features that enhance oil flow and reduce the risk of blockages, contributing to its overall performance and durability 2.

Benefits of Using the Lubricating Oil Supply Tube

Utilizing the Lubricating Oil Supply Tube offers several advantages. It enhances lubrication efficiency by ensuring a steady and reliable supply of oil to engine components. This consistent lubrication contributes to enhanced engine protection, reducing wear and tear on moving parts. Furthermore, the tube’s role in the lubrication system supports overall engine performance and longevity, making it a valuable component for heavy-duty truck engines 3.

Installation and Maintenance

Proper installation of the Lubricating Oil Supply Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure secure connections and optimal performance. Regular maintenance practices, such as checking for leaks, ensuring connections are tight, and inspecting for signs of wear or damage, are recommended to maintain the tube’s efficiency and longevity. Following these guidelines helps in preventing potential issues and ensures the engine’s lubrication system operates at peak performance.

Troubleshooting Common Issues

Common issues associated with the Lubricating Oil Supply Tube include leaks and blockages. Leaks may occur due to worn seals or damaged connections, while blockages can result from debris or sludge within the oil. Troubleshooting these issues involves inspecting the tube and connections for damage, cleaning or replacing parts as necessary, and ensuring the oil is clean and free of contaminants. Addressing these problems promptly helps maintain the efficiency of the lubrication system and protects the engine from potential damage.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing reliable and high-performance components. Their product range includes engines, powertrains, and related technologies, all designed to meet the demanding requirements of various industries. Cummins’ commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted name in the industry.

Cummins Engine Part 4066368: Lubricating Oil Supply Tube

The Cummins part 4066368, known as the Lubricating Oil Supply Tube, is an integral component in the engine’s lubrication system. This part ensures that oil is efficiently and effectively delivered to various engine parts, maintaining optimal lubrication levels and reducing wear and tear.

Application in Cummins Engines

QSK45 CM500

The QSK45 CM500 engine is a high-performance, heavy-duty diesel engine designed for demanding applications. The 4066368 Lubricating Oil Supply Tube is specifically engineered to fit seamlessly within the QSK45 CM500 engine, ensuring that critical engine components receive the necessary lubrication to operate smoothly and efficiently.

QSK Series

The QSK series of engines, including the QSK45 CM500, benefit from the precise engineering of the 4066368 Lubricating Oil Supply Tube. This part is designed to withstand the high pressures and temperatures typical of these engines, providing reliable performance in various industrial and commercial applications.

CM500 Series

The CM500 series engines are known for their durability and efficiency. The 4066368 Lubricating Oil Supply Tube is a key component in these engines, ensuring that the lubrication system functions optimally. This part is designed to integrate smoothly with the CM500 series, contributing to the engine’s overall reliability and performance.

QSK and CM500 Group

When considering the QSK and CM500 engines together, the 4066368 Lubricating Oil Supply Tube plays a crucial role in maintaining the integrity of the lubrication system. This part is designed to fit both series, ensuring that the engines benefit from consistent and reliable lubrication, which is essential for their longevity and performance.

Role of Part 4066368 Lubricating Oil Supply Tube in Engine Systems

The part 4066368 Lubricating Oil Supply Tube is an essential component in the lubrication system of various engine setups. Its primary function is to facilitate the smooth and consistent flow of lubricating oil from the oil pan to other critical engine components.

In the context of the oil pan, the 4066368 tube acts as a conduit, drawing oil from the reservoir and transporting it to the engine’s lubrication points. This ensures that all moving parts, such as bearings, pistons, and camshafts, receive a continuous supply of oil, which is vital for reducing friction and wear.

Additionally, the tube plays a significant role in maintaining oil pressure within the system. By efficiently channeling oil, it helps in stabilizing pressure levels, which is important for the proper functioning of the oil pump and other lubrication-dependent components.

Furthermore, the 4066368 tube contributes to the overall efficiency of the lubrication system. Its design and placement are optimized to minimize resistance and turbulence in the oil flow, which enhances the system’s ability to deliver oil promptly and effectively to where it is needed most.

Conclusion

In summary, the 4066368 Lubricating Oil Supply Tube is a key element in ensuring that engine components are adequately lubricated, thereby promoting longevity and reliable performance of the engine. Its role in the lubrication system is critical for maintaining the efficiency and durability of heavy-duty truck engines.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.