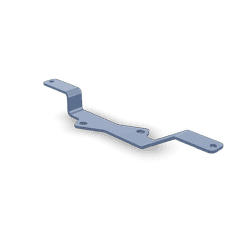

4065718

Oil Tube Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Tube Bracket (Part #4065718) by Cummins is a component designed for use in commercial trucks. Its purpose is to support and secure the oil tubes within the engine system, ensuring that oil is efficiently routed to various engine components. This part plays a role in maintaining the integrity of the oil system by preventing leaks and ensuring consistent oil flow, which is vital for the engine’s operation 1.

Purpose and Function

The Oil Tube Bracket serves to facilitate the routing and securement of oil tubes in a truck’s engine system. By providing a stable mounting point, it ensures that oil tubes remain in place and are not subjected to undue stress or movement. This securement is crucial for maintaining efficient oil flow to critical engine components, which helps in lubrication, cooling, and overall engine performance. Additionally, the bracket reduces the risk of oil leaks by keeping the tubes properly aligned and supported 2.

Key Features

The Cummins Oil Tube Bracket is engineered with several key features that enhance its performance and durability. It is constructed from high-strength materials to withstand the rigors of commercial truck operation. The design includes precise mounting points and securement mechanisms to ensure that oil tubes are held firmly in place. Additionally, the bracket is designed to be compatible with various Cummins engine models, providing versatility and ease of use 3.

Benefits

The use of the Oil Tube Bracket offers several benefits. It contributes to improved engine performance by ensuring consistent and efficient oil flow. Secure management of oil tubes enhances safety by reducing the risk of leaks, which can lead to engine damage or failure. Furthermore, the bracket can lead to potential cost savings by minimizing maintenance needs and extending the lifespan of the oil system components.

Installation and Compatibility

Proper installation of the Oil Tube Bracket involves several steps to ensure it is securely mounted and correctly aligned with the oil tubes. Tools such as wrenches and alignment gauges may be required. It is important to follow the manufacturer’s guidelines to achieve a proper fit and function. The bracket is designed to be compatible with a range of Cummins engine models, ensuring it can be used across different truck systems without requiring significant modifications.

Maintenance and Troubleshooting

Regular maintenance of the Oil Tube Bracket is important to ensure its longevity and effectiveness. This includes periodic inspections for signs of wear or damage, ensuring that all mounting points are secure, and verifying that oil tubes are properly aligned. Common issues that may arise include loose mounting points or damaged brackets, which can be addressed by re-securing the bracket or replacing damaged components as necessary.

Safety Considerations

When installing, maintaining, or troubleshooting the Oil Tube Bracket, it is important to observe several safety practices. Ensure that the engine is turned off and cooled down before beginning any work to avoid burns or injuries. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Additionally, be mindful of the high-pressure oil system and take care to avoid leaks, which can pose a safety risk.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in automotive components. Founded in 1919, Cummins has a long history of providing reliable and high-performance engine solutions. The company’s dedication to engineering excellence is evident in its wide range of products, including the Oil Tube Bracket, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Oil Tube Bracket 4065718 Compatibility

The Cummins Oil Tube Bracket part number 4065718 is designed to fit a range of Cummins engines, ensuring secure and efficient oil tube routing. This bracket is integral for maintaining the integrity of the engine’s oil system. Below is a detailed overview of its compatibility with various Cummins engines:

QSK45 CM500 and QSK60 CM500

The Oil Tube Bracket 4065718 is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of the Cummins QSK series, known for their robust performance and reliability in heavy-duty applications. The bracket ensures that the oil tubes are properly aligned and secured, preventing any potential leaks or misalignments that could compromise engine performance.

QSK60 CM850 MCRS

The Oil Tube Bracket 4065718 also fits the QSK60 CM850 MCRS engine. This engine is designed for demanding applications, providing high power output and efficiency. The bracket’s design accommodates the specific layout and requirements of the CM850 MCRS engine, ensuring that the oil tubes are correctly positioned and supported.

QSK60G

Lastly, the Oil Tube Bracket 4065718 is suitable for the QSK60G engine. This engine is part of the Cummins QSK series, offering a balance of power and efficiency. The bracket’s fitment is crucial for maintaining the structural integrity of the oil system, ensuring that the engine operates smoothly and reliably.

Conclusion

In summary, the Cummins Oil Tube Bracket 4065718 is engineered to fit a variety of Cummins engines, providing a secure and efficient solution for oil tube routing across different engine models. This part plays a significant role in the engine’s lubrication system by securely holding the oil tube in place, thereby ensuring a steady supply of lubricating oil to the engine components.

References

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Harald Naunheimer, Bernd Bertsche, Joachim Ryborz, Wolfgang Novak, Automotive Transmissions Fundamentals Selection Design and Application, Springer Vieweg, 2011.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.