This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

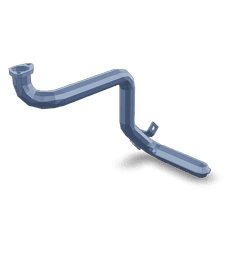

The 4063717 Oil Suction Connection is a specialized component designed for use in commercial trucks, specifically within the engine’s lubrication system. Manufactured by Cummins, a renowned name in the commercial truck industry, this part ensures the efficient transfer of oil from the sump to the engine, thereby providing adequate lubrication to all moving parts. This is crucial for maintaining engine health, reducing friction, and preventing wear 1.

Basic Concepts of Oil Suction Connection

An oil suction connection is integral to the lubrication system of a truck engine. It draws oil from the sump and directs it to the engine’s lubrication points. This process is essential for maintaining engine health by ensuring that all moving parts are adequately lubricated, which reduces friction and wear. Proper lubrication is fundamental to the longevity and efficiency of the engine 2.

Purpose of the 4063717 Oil Suction Connection

The 4063717 Oil Suction Connection facilitates the smooth flow of oil from the sump to the engine. This ensures that oil reaches the engine components under the necessary pressure and volume, supporting optimal engine performance and protection against wear and damage 3.

Key Features

This Cummins part is constructed from high-quality materials designed to withstand the harsh conditions within a truck engine. It is engineered to provide a secure and leak-free fit, ensuring efficient oil transfer without loss. The design may also include features that facilitate easy installation and maintenance, contributing to its overall effectiveness.

Benefits

Using the 4063717 Oil Suction Connection results in improved oil flow, leading to better lubrication of engine components. This enhances engine protection against wear and reduces the risk of damage due to insufficient lubrication. Its reliability in heavy-duty applications makes it a valuable component for commercial trucks, ensuring smooth and efficient engine operation under demanding conditions.

Installation Considerations

When installing the 4063717, it is important to follow guidelines and best practices to ensure compatibility with the specific engine model and to achieve a secure fit. The necessary tools and equipment should be used to facilitate a proper installation, which is crucial for the component’s performance and the engine’s overall health.

Maintenance and Care

Routine maintenance and care of the 4063717 are recommended to ensure its longevity and optimal performance. This includes regular inspection intervals to check for signs of wear or damage and cleaning procedures to remove any contaminants that may affect its function. Proper maintenance helps to prevent issues such as leaks or blockages, ensuring the continued efficient operation of the lubrication system.

Troubleshooting Common Issues

Common problems associated with oil suction connections, such as leaks or blockages, can often be identified through routine inspections. Troubleshooting steps may include checking for proper installation, ensuring there are no obstructions in the oil path, and verifying that all connections are secure. Addressing these issues promptly can help maintain the efficiency of the lubrication system and protect the engine from potential damage.

Compatibility with Cummins Engines

The 4063717 is compatible with several Cummins engine models, including:

- 6C8.3

- QSC8.3 CM850 (CM2850)

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

This part is engineered to meet the specific requirements of these engines, ensuring optimal performance and longevity.

Role of Part 4063717 Oil Suction Connection in Engine Systems

The 4063717 is an essential component in the lubrication system of an engine. It is designed to facilitate the efficient transfer of oil from the oil pan to the engine’s oil pump.

Integration with the Oil Pan

The Oil Suction Connection is typically mounted on the oil pan, which serves as the reservoir for the engine’s lubricant. The connection point ensures a secure and leak-free interface between the oil pan and the suction line leading to the oil pump. This setup allows for consistent and reliable oil flow, which is vital for maintaining proper lubrication throughout the engine.

Function in the Lubrication Circuit

Once the Oil Suction Connection draws oil from the pan, it channels it through the suction line to the oil pump. The oil pump then pressurizes the oil and distributes it to various engine components, including bearings, pistons, and camshafts. This continuous circulation ensures that all moving parts are adequately lubricated, reducing friction and wear.

Maintenance and Efficiency

Regular inspection and maintenance of the Oil Suction Connection are important to ensure it remains in optimal condition. Any leaks or blockages in this component can lead to insufficient oil supply to the pump, potentially causing engine damage due to inadequate lubrication. Therefore, ensuring the integrity of the Oil Suction Connection contributes significantly to the overall efficiency and longevity of the engine.

Conclusion

The 4063717 Oil Suction Connection by Cummins is a critical component in the lubrication system of commercial truck engines. Its design and features ensure efficient oil transfer, contributing to engine longevity and performance. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part and ensure the engine operates smoothly under demanding conditions.

-

The Motor Vehicle, TK Garrett, K Newton, W Steeds, Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Reducing Particulate Emissions in Gasoline Engines, Thorsten Boger, Willard Cutler, SAE International, 2018.

↩ -

Advanced Direct Injection Combustion Engine Technologies and Development Volume 2 Diesel Engines, Hua Zhao, CRC Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.