4059442

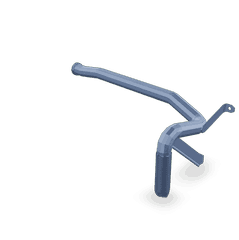

Oil Suction Connection

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Oil Suction Connection 4059442, manufactured by Cummins, is a component designed to facilitate the efficient operation of commercial truck engines. This part is integral to the lubrication system, ensuring that engine components receive the necessary oil for smooth operation and longevity. Cummins, a renowned name in the automotive industry, produces this component with a focus on reliability and performance 1.

Basic Concepts of Oil Suction Connection

An oil suction connection is a vital element in the lubrication system of a truck engine. Its primary function is to draw oil from the sump—the lowest point in the engine where oil collects—and direct it to various engine components that require lubrication. This process is essential for reducing friction, dissipating heat, and protecting engine parts from wear and tear. The efficiency of this connection directly impacts the overall health and performance of the engine 2.

Role of the 4059442 Oil Suction Connection in Truck Operation

The 4059442 Oil Suction Connection plays a specific role in the lubrication system by ensuring a consistent flow of oil from the sump to the engine’s moving parts. This connection is designed to handle the demands of commercial truck engines, which operate under heavy loads and varying conditions. By maintaining a steady supply of oil, it helps in reducing friction between moving parts, cooling critical components, and carrying away contaminants, thereby contributing to the engine’s efficiency and durability 3.

Key Features

The 4059442 Oil Suction Connection is characterized by its robust design and the use of high-quality materials. These features are intended to enhance its performance and durability in the demanding environment of a commercial truck engine. The connection is engineered to withstand high pressures and temperatures, ensuring reliable operation over the engine’s lifespan. Its design also facilitates easy installation and maintenance, contributing to the overall efficiency of engine care routines 4.

Benefits

The use of the 4059442 Oil Suction Connection in a truck’s engine lubrication system offers several benefits. It contributes to improved engine lubrication by ensuring a consistent oil flow to critical components. This consistent lubrication helps in enhancing the engine’s durability by reducing wear on moving parts. Additionally, by maintaining optimal lubrication, the connection can play a part in the overall efficiency and longevity of the engine 5.

Troubleshooting and Maintenance

To ensure the optimal performance and longevity of the 4059442 Oil Suction Connection, regular maintenance and troubleshooting are recommended. Common issues may include blockages or leaks, which can affect the efficiency of oil flow. Regular inspections and cleaning of the connection can help prevent such issues. In case of leaks or significant wear, replacement or repair may be necessary to maintain the integrity of the lubrication system 6.

Compatibility with Cummins Engines

This Oil Suction Connection is compatible with several Cummins engine models, including:

- ISX CM570

- ISX CM870

- ISX CM871

- ISX15 CM2250

- ISX15 CM2250 SN

- ISX15 CM2350 X101

- QSX15 CM2250 ECF

- QSX15 CM2350 X105

- X15 CM2350 X116B

- X15 CM2350 X123B

- X15 CM2450 X134B

Each of these engines relies on the Oil Suction Connection to maintain proper oil pressure and flow, ensuring that the engine operates smoothly and efficiently. The part’s design and material quality are critical to its performance, as it must withstand the high pressures and temperatures within the engine’s oil system 7.

Interaction with the Oil Pan

The oil suction connection is mounted on the oil pan, which serves as the reservoir for the engine’s lubricant. The connection point allows for a secure and leak-proof attachment, ensuring that the oil can be drawn from the pan without any loss. This is essential for maintaining the proper oil level and pressure within the engine 8.

Oil Suction Process

Once attached, the 4059442 oil suction connection works in conjunction with the oil pump. The pump creates a vacuum that pulls oil through the suction connection and into the pump intake. This continuous flow of oil is vital for lubricating moving parts, reducing friction, and dissipating heat within the engine 9.

Ensuring System Integrity

The design of the 4059442 oil suction connection also plays a role in maintaining the integrity of the lubrication system. By providing a reliable connection point, it helps prevent oil leaks, which could lead to decreased oil pressure and potential engine damage. Additionally, its placement and design contribute to the overall efficiency of the oil circulation, ensuring that all engine components receive adequate lubrication 10.

Conclusion

The 4059442 Oil Suction Connection is a critical component in the lubrication system of Cummins engines, ensuring efficient oil flow and maintaining engine health. Its robust design, compatibility with various engine models, and ease of maintenance make it a reliable choice for commercial truck operators. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part.

-

Harrison, M. (2004). Controlling Noise and Vibration in Road Vehicles. SAE International.

↩ -

Ribbens, W. B. (2003). Understanding Automotive Electronics. Elsevier Science.

↩ -

Parikyan, T. Ed. (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual, Bulletin Number 5411132, ISB6.7 CM2350 B142 Stop-Start Applications.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.