This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

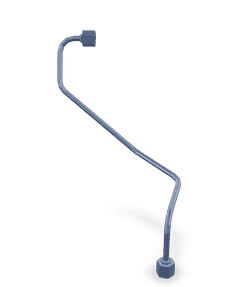

The Lubricating Oil Supply Tube, identified by Part #4013162, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industry. This tube plays a role in the lubrication system of heavy-duty truck engines, ensuring that oil is efficiently delivered to various engine components. Cummins is renowned for its commitment to quality and innovation, making this part a reliable choice for fleet operators and maintenance professionals.

Function and Operation

The Lubricating Oil Supply Tube operates as a conduit within the engine lubrication system. Its role is to deliver oil from the oil pump to different parts of the engine, including the crankshaft, camshaft, and other moving components. By ensuring a consistent flow of oil, the tube helps in reducing friction, dissipating heat, and protecting engine parts from wear and tear. The efficient operation of this tube is fundamental to maintaining the overall health and performance of the engine 1.

Key Features

The Lubricating Oil Supply Tube is designed with several features that enhance its durability and performance. Constructed from high-quality materials, it is built to withstand the high pressures and temperatures within the engine environment. The tube’s design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, its robust construction contributes to longevity, reducing the need for frequent replacements 2.

Benefits of Using the Lubricating Oil Supply Tube

Utilizing the Lubricating Oil Supply Tube offers several advantages. It contributes to improved lubrication efficiency, which in turn enhances engine performance and reliability. The consistent delivery of oil helps in maintaining optimal engine operation, potentially leading to cost savings for fleet operators through reduced maintenance needs and extended engine life. Furthermore, the high-quality construction of the tube ensures that it can withstand the demanding conditions of heavy-duty truck engines 3.

Installation and Maintenance

Proper installation of the Lubricating Oil Supply Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper alignment with other components. Regular maintenance, including checks for leaks and wear, is recommended to ensure optimal performance. Troubleshooting common issues, such as leaks or blockages, can often be addressed through careful inspection and timely replacement of worn parts 4.

Safety Considerations

When working with the Lubricating Oil Supply Tube, it is important to follow safety precautions. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning any work, and following proper handling and storage procedures for the tube. Additionally, any disposal of the tube should be done in accordance with local regulations to ensure environmental safety.

Environmental Impact

The use and disposal of the Lubricating Oil Supply Tube have environmental considerations. Efforts should be made to recycle materials where possible and to dispose of the tube in an environmentally responsible manner. Cummins is committed to sustainability and innovation, working towards minimizing waste and promoting recycling within the automotive industry.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a history of innovation and a commitment to sustainability, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from on-highway to off-highway and stationary power. The company’s dedication to quality and performance is evident in its product offerings, including the Lubricating Oil Supply Tube.

Cummins Lubricating Oil Supply Tube 4013162 Compatibility

The Cummins part number 4013162, which is a Lubricating Oil Supply Tube, is designed to fit seamlessly with several engine models. This part is crucial for ensuring that the engine receives a steady and reliable supply of lubricating oil, which is essential for maintaining engine performance and longevity.

Compatible Engines

QSV91-G4 CM558/CM700 V102

This engine model benefits from the precise fit and functionality of the 4013162 oil supply tube. The design of this part ensures that it integrates smoothly with the engine’s architecture, providing an uninterrupted flow of oil to critical components.

QSV91G

Similarly, the QSV91G engine is another model that is compatible with the 4013162 oil supply tube. This part is engineered to meet the specific requirements of this engine, ensuring optimal performance and reliability.

Grouping of Compatible Engines

The engines listed above, QSV91-G4 CM558/CM700 V102 and QSV91G, share common design elements that make them suitable for the 4013162 oil supply tube. This compatibility is due to the standardized design and functionality of the part, which is tailored to fit these specific engine models.

By ensuring that the 4013162 oil supply tube is used with the correct engine models, users can maintain the integrity and efficiency of their engines, preventing potential issues related to oil supply disruptions.

Role of Part 4013162 Lubricating Oil Supply Tube in Engine Systems

The lubricating oil supply tube, part 4013162, is integral to maintaining the efficiency and longevity of various engine components. It ensures a consistent flow of lubricating oil to key areas, facilitating smooth operation and reducing wear.

Block

Within the engine block, the lubricating oil supply tube delivers oil to the main bearings and crankshaft journals. This consistent lubrication minimizes friction between moving parts, ensuring the crankshaft operates smoothly and efficiently. Proper lubrication also helps in dissipating heat generated during engine operation, contributing to the overall stability and performance of the engine block.

Cylinder

The cylinder benefits from the lubricating oil supply tube by receiving a steady stream of oil to the cylinder walls. This lubrication reduces friction between the piston rings and the cylinder walls, promoting a tighter seal and enhancing combustion efficiency. Additionally, it helps in cooling the cylinder walls, preventing overheating and potential damage.

Follower

For the valve train components, such as the followers, the lubricating oil supply tube ensures that oil reaches the cam-follower interface. This lubrication is essential for reducing wear on the followers, which are subject to high cyclic loads and speeds. Smooth operation of the followers directly impacts valve timing and engine performance, making consistent lubrication vital.

Cam

The camshaft, another critical component in the valve train, relies on the lubricating oil supply tube to receive oil at the cam lobes and bearings. This lubrication is necessary to reduce friction and wear on the cam lobes as they interact with the followers. It also ensures that the camshaft bearings operate smoothly, contributing to precise valve actuation and overall engine efficiency.

In summary, part 4013162 plays a role in delivering lubricating oil to these engine components, ensuring they function optimally and endure the rigors of engine operation.

Conclusion

The Lubricating Oil Supply Tube, part 4013162, is a critical component in the lubrication system of heavy-duty truck engines. Its role in delivering oil to various engine components ensures reduced friction, heat dissipation, and protection from wear and tear. The tube’s durable construction, precise design, and compatibility with specific engine models make it a reliable choice for maintaining engine performance and longevity. Proper installation, regular maintenance, and adherence to safety and environmental guidelines are essential for maximizing the benefits of this Cummins part.

-

Department of Energy Fundamentals Handbook, Department of Energy, 2015

↩ -

Design and Development of Heavy Duty Diesel Engines: A Handbook, P. A. Lakshminarayanan and Avinash Kumar, Springer Nature, 2020

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩ -

General Information, Bulletin Number 3666136, Operation and Maintenance Manual

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.