This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

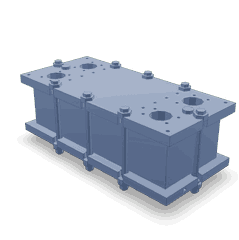

The Cummins 4012789 Oil Cooler is a component designed to regulate the temperature of engine oil in commercial trucks. It is integral to maintaining the operational efficiency and longevity of the engine. By ensuring that the oil remains within optimal temperature ranges, the oil cooler contributes to the overall performance and reliability of the truck’s engine system 1.

Basic Concepts of Oil Coolers

An oil cooler is a heat exchanger that helps manage the temperature of engine oil. It operates by transferring excess heat from the oil to the surrounding air or coolant, depending on the design. This process is vital for maintaining the viscosity and lubricating properties of the oil, which are essential for the engine’s moving parts. The principles of heat exchange involved in oil cooling include conduction, convection, and radiation, which facilitate the efficient transfer of heat away from the oil 2.

Purpose of the Cummins 4012789 Oil Cooler

The Cummins 4012789 Oil Cooler plays a role in maintaining optimal engine oil temperature by dissipating excess heat generated during engine operation. This helps ensure efficient engine performance by keeping the oil within its ideal temperature range, which is necessary for proper lubrication and reducing wear on engine components. Additionally, it contributes to prolonging engine life by preventing overheating, which can lead to oil breakdown and increased engine wear 3.

Key Features

The Cummins 4012789 Oil Cooler is characterized by its robust design and the use of high-quality materials. It features a compact yet efficient structure that maximizes heat exchange while minimizing space requirements. The cooler is constructed from durable materials that resist corrosion and withstand the harsh conditions typical of commercial truck operations. Unique attributes include enhanced heat transfer capabilities and a design that promotes easy installation and maintenance 4.

Benefits of Using the Cummins 4012789 Oil Cooler

Incorporating the Cummins 4012789 Oil Cooler into a truck’s engine system offers several advantages. It improves engine efficiency by ensuring that the oil remains at an optimal temperature, which enhances lubrication and reduces friction. This can lead to lower fuel consumption and reduced emissions. Additionally, the cooler reduces the risk of overheating, which can cause engine damage. Enhanced overall reliability is another benefit, as maintaining proper oil temperature contributes to the longevity and consistent performance of the engine 5.

Installation and Integration

Proper installation of the Cummins 4012789 Oil Cooler is crucial for its effective operation. It is designed to be compatible with a range of truck models, ensuring seamless integration into existing engine systems. Installation guidelines recommend following manufacturer specifications to ensure correct fitting and operation. This includes verifying compatibility with the truck’s engine model and ensuring that all connections are secure and leak-free 6.

Maintenance and Care

Regular maintenance practices are recommended to ensure the longevity and effectiveness of the Cummins 4012789 Oil Cooler. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could impede heat exchange, and checking for leaks. Adhering to manufacturer-recommended inspection intervals and maintenance procedures will help maintain the cooler’s performance and extend its service life 7.

Troubleshooting Common Issues

Common problems associated with oil coolers, such as leaks or reduced efficiency, can often be addressed through routine maintenance and inspections. If a leak is detected, it is important to identify the source and repair or replace the affected component. Reduced efficiency may indicate a buildup of contaminants or a failure in the heat exchange process, which can be addressed through cleaning or, in some cases, replacement of the cooler 8.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to producing high-quality engine components. The company’s dedication to excellence is evident in its range of products, including the 4012789 Oil Cooler, which is designed to meet the demanding requirements of commercial truck applications 9.

Compatibility of Cummins Oil Cooler Part 4012789

The Cummins Oil Cooler part number 4012789 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This oil cooler is engineered to dissipate heat effectively, maintaining the oil’s viscosity and preventing engine overheating.

QSV91-G4 CM558/CM700 V102

The Oil Cooler part 4012789 is compatible with the QSV91-G4 CM558/CM700 V102 engines. This compatibility ensures that the oil cooler can efficiently manage the heat generated by these engines, contributing to their overall efficiency and reliability.

QSV91G

Similarly, the Oil Cooler part 4012789 is also suitable for the QSV91G engine. This part is engineered to fit precisely, providing the necessary cooling to maintain the engine’s optimal operating temperature.

By ensuring that the oil cooler fits these specific engine models, Cummins guarantees that the cooling system operates effectively, thereby enhancing the engine’s performance and lifespan 10.

Role of Part 4012789 Oil Cooler in Engine Systems

In engine systems, the integration of part 4012789, the Oil Cooler, is fundamental for maintaining optimal operating temperatures of the engine oil. This component works in tandem with the engine oil system to ensure that the oil remains within a specified temperature range, which is essential for the lubrication, cooling, and cleaning functions that the oil performs.

The Oil Cooler achieves this by circulating the engine oil through a series of tubes or fins that are exposed to either air or a coolant fluid. As the oil passes through these pathways, heat is dissipated, reducing the oil’s temperature before it is recirculated back into the engine. This process is particularly important in high-performance or high-stress engine environments where the oil can reach temperatures that may degrade its lubricating properties or even cause it to break down.

Moreover, the Oil Cooler’s role extends to protecting other engine components. By keeping the oil at a stable temperature, it helps to prevent thermal expansion that can lead to seal failures or increased wear on moving parts. It also aids in the prevention of sludge formation, which can occur when oil is exposed to excessive heat over time.

In summary, the incorporation of part 4012789 into engine systems is a strategic move to enhance the longevity and efficiency of the engine. It ensures that the engine oil maintains its integrity and performs its intended functions effectively throughout the engine’s operational life 11.

Conclusion

The Cummins 4012789 Oil Cooler is a vital component in the maintenance of engine oil temperature, ensuring optimal engine performance and longevity. Its robust design, compatibility with various engine models, and the benefits it offers in terms of engine efficiency and reliability make it a valuable addition to commercial truck engine systems. Regular maintenance and proper installation are key to maximizing the effectiveness of this Cummins part.

-

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩ -

Richards, Paul, and Jim Barker. Automotive Fuels Reference Book. SAE International, 2023.

↩ -

Crolla, David. Crolla Encyclopedia. Wiley, 2015.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Lejda, Kazimierz, and Pawel Wos. Internal Combustion Engines. InTech, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.