This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4009465 Lubricating Oil Drain Tube by Cummins is a component designed to facilitate the efficient drainage of lubricating oil from heavy-duty truck engines. This part is integral to the maintenance and operational efficiency of these vehicles, ensuring that oil changes are conducted smoothly and effectively 1.

Basic Concepts of Lubricating Oil Drain Tubes

A Lubricating Oil Drain Tube is a conduit that allows used oil to be expelled from the engine during an oil change. Within the engine system, it plays a role by providing a pathway for oil to flow from the sump to a collection point, ensuring that the engine remains properly lubricated and that old oil is efficiently removed. Proper lubrication is vital for engine performance and longevity, as it reduces friction between moving parts, minimizes wear, and helps dissipate heat 2.

Purpose of the 4009465 Lubricating Oil Drain Tube

The 4009465 Lubricating Oil Drain Tube is specifically engineered to enhance the oil drainage process in heavy-duty trucks. It ensures that oil is effectively channeled away from the engine during maintenance routines, which is crucial for maintaining engine health and performance. By facilitating quick and clean oil changes, this component helps in preserving the engine’s efficiency and reliability over time 3.

Key Features

The 4009465 Lubricating Oil Drain Tube is constructed with high-quality materials that offer durability and resistance to the harsh conditions within a truck engine. Its design includes features that enhance performance, such as a secure fitting mechanism that prevents leaks and ensures a tight seal. The tube is also designed to withstand high temperatures and pressures, making it suitable for the demanding environments of heavy-duty applications 4.

Benefits

Using the 4009465 Lubricating Oil Drain Tube offers several advantages. It contributes to improved engine efficiency by ensuring that oil changes are conducted without complications. The design of the tube reduces maintenance time, as it allows for quicker and more efficient oil drainage. Additionally, its robust construction enhances the reliability of the oil drainage system, leading to fewer interruptions in service and longer engine life 1.

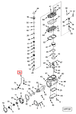

Installation Process

Installing the 4009465 Lubricating Oil Drain Tube requires careful attention to ensure a secure fit. The process involves removing the old tube, cleaning the area around the sump, and then fitting the new tube into place. Tools such as wrenches and sealant may be required to complete the installation. Following the manufacturer’s guidelines ensures that the tube is installed correctly, providing a reliable seal and efficient oil drainage 3.

Troubleshooting Common Issues

Common issues with Lubricating Oil Drain Tubes may include leaks or blockages. Leaks can often be traced to improper installation or wear on the tube, while blockages may result from debris within the oil. Diagnosing these problems involves inspecting the tube for signs of damage or obstruction and addressing them promptly to prevent further complications 2.

Maintenance Tips

Regular maintenance of the 4009465 Lubricating Oil Drain Tube is important for ensuring its longevity and optimal performance. This includes periodic inspections for signs of wear or damage, cleaning the tube to remove any buildup, and ensuring that all connections are secure. Adhering to a maintenance schedule helps in identifying potential issues before they lead to more significant problems 4.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its diesel engines and related components. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance parts. Their product range includes a variety of engine components designed to meet the needs of heavy-duty applications, ensuring that vehicles operate efficiently and reliably 1.

Cummins Engine Compatibility with Lubricating Oil Drain Tube Part 4009465

The Cummins part number 4009465, which is a Lubricating Oil Drain Tube, is designed to fit seamlessly within a range of Cummins engines. This part is crucial for the maintenance and operational efficiency of the engines, ensuring that oil is properly drained from the engine’s sump, thereby preventing oil contamination and maintaining optimal engine performance 3.

QSK19 CM500 Engines

The QSK19 CM500 engine series, known for its robust design and high performance, is one of the engines that can utilize the 4009465 Lubricating Oil Drain Tube. This engine is often employed in heavy-duty applications, including marine and industrial sectors, where reliability and durability are paramount. The 4009465 part ensures that the oil drainage process is efficient, reducing the risk of engine wear and extending the engine’s lifespan 4.

Grouping of Compatible Engines

While the QSK19 CM500 is a notable example, the 4009465 Lubricating Oil Drain Tube is also compatible with other Cummins engines within the same family or similar configurations. These engines share common design principles and maintenance requirements, making the 4009465 part a versatile choice for multiple engine models. The compatibility extends to engines that are part of the same engine family, ensuring that the part can be used across various models without modification 1.

Importance of Proper Installation

Proper installation of the 4009465 Lubricating Oil Drain Tube is essential to maintain the integrity of the engine’s lubrication system. This part must be correctly aligned and securely fastened to prevent leaks and ensure that oil drains effectively. Regular inspection and replacement of this part, as per the manufacturer’s recommendations, are critical for maintaining engine health and performance 2.

Role of Part 4009465 Lubricating Oil Drain Tube in Compressor and Air Systems

In the context of compressor and air systems, the lubricating oil drain tube (Part 4009465) serves an essential function in maintaining the efficiency and longevity of these systems.

Compressor Systems

Within compressor systems, the lubricating oil drain tube is integral to the oil management subsystem. It facilitates the removal of used lubricating oil from the compressor, ensuring that the oil does not accumulate to levels that could impair compressor performance. The tube directs the drained oil to a collection point, typically a sump or reservoir, where it can be filtered and recirculated or disposed of appropriately. This process helps in maintaining optimal lubrication levels, reducing friction and wear on moving parts, and preventing overheating 3.

Air Systems

In air systems, particularly those involving pneumatic tools or air compressors, the lubricating oil drain tube plays a role in preserving the quality of the compressed air. By efficiently draining lubricants that may have been introduced into the air stream during compression, the tube helps in preventing contamination of the air supply. This is particularly important in applications where clean, dry air is required, such as in food and beverage processing or in sensitive electronic manufacturing environments. The drained oil is collected and managed separately, ensuring that the air delivered to end-users remains free from oil residues, thus maintaining system integrity and performance 4.

Conclusion

The 4009465 Lubricating Oil Drain Tube by Cummins is a critical component for maintaining the efficiency and reliability of heavy-duty truck engines. Its design and construction ensure that oil changes are conducted efficiently, reducing maintenance time and enhancing engine performance. Proper installation and regular maintenance of this part are essential for ensuring the longevity and optimal operation of the engine. Additionally, its compatibility with various Cummins engines makes it a versatile choice for multiple applications, further underscoring its importance in heavy-duty engine maintenance 1234.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ ↩ ↩ ↩ ↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ ↩ ↩ ↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ ↩ ↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.