4007927

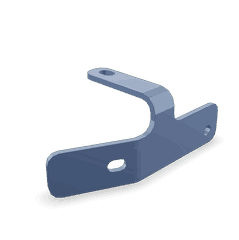

Oil Tube Bracket

Cummins®

AVAILABLE

4 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4007927 Oil Tube Bracket is a component designed to support and route oil tubes within the lubrication system of commercial truck engines. Its role is significant in maintaining the efficient operation of the engine by ensuring proper oil flow to critical components 1.

Purpose and Function

The Oil Tube Bracket serves to secure and direct oil tubes in the engine’s lubrication system. By holding the tubes in place, it facilitates the smooth and consistent flow of oil to various engine parts, which is vital for reducing friction and wear 2. This bracket ensures that oil is delivered where it is needed most, contributing to the overall efficiency and longevity of the engine.

Key Features

The design of the 4007927 incorporates robust materials that are resistant to the harsh conditions within an engine environment. Its construction is tailored to withstand high temperatures and mechanical stresses. Unique attributes of this bracket include precision engineering for a secure fit and durable materials that enhance its performance and longevity 3.

Benefits

Utilizing the Cummins Oil Tube Bracket offers several advantages. It contributes to improved engine lubrication by ensuring that oil is efficiently distributed throughout the engine. This can lead to reduced risk of oil leaks, which are common in poorly secured or worn-out brackets. Additionally, the enhanced lubrication supports better overall engine performance and reliability 4.

Installation Process

Proper installation of the Oil Tube Bracket is crucial for its effective operation. The process involves positioning the bracket correctly within the engine compartment and securing it with the appropriate fasteners. Careful attention to the manufacturer’s guidelines ensures that the bracket is installed in a manner that optimizes its functionality and integrates seamlessly with the engine’s lubrication system 5.

Maintenance and Troubleshooting

Regular maintenance of the Oil Tube Bracket is important to prevent issues such as oil leaks or reduced efficiency. This includes checking for signs of wear or damage and ensuring that all connections are secure. Common problems may include loose fittings or corrosion, which can be addressed by tightening connections or applying a suitable protective coating 6.

Compatibility and Applications

The 4007927 is designed for use with specific types of engines and truck models. Its application is tailored to meet the demands of various commercial truck settings, ensuring that it provides reliable performance across different operating conditions 7.

Safety Considerations

When working with the Oil Tube Bracket, it is important to follow safety guidelines to protect both the individual and the component. This includes wearing appropriate personal protective equipment and ensuring that the engine is cool before beginning any work. Additionally, careful handling of the bracket during installation and maintenance helps to preserve its integrity and functionality 8.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its commitment to quality and innovation. The company has a history of producing reliable and high-performance truck components, including the 4007927 Oil Tube Bracket. Cummins’ reputation is built on its dedication to excellence in manufacturing and its continuous pursuit of advancements in truck technology 9.

Compatibility

QSK78 Series

The QSK78 series engines, including the QSK78 CM500, are high-performance engines known for their robust design and reliability. The Oil Tube Bracket 4007927 is specifically tailored to fit within the intricate layout of these engines. It ensures that the oil tubes are properly anchored, preventing any misalignment or movement that could lead to oil leaks or inefficient oil circulation. This is crucial for maintaining optimal engine performance and longevity 10.

CM500 Series

The CM500 series engines, part of the Cummins lineup, are engineered for demanding applications. The Oil Tube Bracket 4007927 is designed to integrate seamlessly with these engines, providing the necessary support for the oil tubes. This bracket is essential for maintaining the structural integrity of the engine’s oil system, ensuring that the oil tubes remain in their designated positions under all operating conditions. Proper installation of this bracket is vital for the efficient operation of the engine, as it directly impacts the oil flow and pressure within the engine 11.

Role of Part 4007927 Oil Tube Bracket in Engine Systems

The 4007927 Oil Tube Bracket is an essential component in the assembly and functionality of engine systems, particularly in relation to the oil level gauge and its location within the engine compartment.

Integration with Oil Level Gauge

The Oil Tube Bracket securely holds the oil tube in place, which is a conduit for the oil level gauge. This bracket ensures that the oil tube remains stable and correctly positioned, allowing for accurate readings of the oil level within the engine. The stability provided by the bracket prevents any undue stress on the oil tube, which could otherwise lead to leaks or inaccurate gauge readings 12.

Positioning and Location

In terms of location, the Oil Tube Bracket is strategically placed to facilitate easy access for maintenance and inspection. Its design allows for the oil tube to be routed efficiently from the oil tank to the gauge, minimizing the risk of kinks or bends that could impede oil flow or damage the tube. The bracket’s placement also considers the overall engine layout, ensuring that it does not interfere with other components or engine operations 13.

Conclusion

The Oil Tube Bracket’s role extends beyond mere support; it is integral to the engine’s lubrication system, ensuring that the oil level gauge provides reliable data for engine health monitoring. Its proper installation and maintenance are key to the engine’s efficient operation and longevity.

-

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

General Information, Bulletin Number 4915536, Owners Manual.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩ -

Asef, Pedram, Sanjeevikumar Padmanaban, and Andrew Lapthorn. Modern Automotive Electrical Systems. Wiley, 2022.

↩ -

Reif, Konrad Ed. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.