This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Lubricating Oil Supply Tube (Part #4001258) by Cummins is a critical component designed to facilitate the efficient delivery of lubricating oil within the engine system of heavy-duty trucks. This part is essential for maintaining the smooth operation and longevity of the engine by ensuring that vital components receive a consistent supply of oil. Its role in the lubrication system highlights the importance of reliable oil delivery for the overall performance and durability of heavy-duty engines 1.

Function and Operation

The Lubricating Oil Supply Tube serves as a conduit within the engine lubrication system, responsible for delivering oil from the oil pump to critical engine components such as bearings, pistons, and other moving parts. By ensuring a steady flow of oil, it contributes to reducing friction and wear, thereby enhancing the efficient operation of the engine. The tube’s design allows for precise oil distribution, which is vital for maintaining optimal engine performance under various operating conditions 2.

Key Features

The Lubricating Oil Supply Tube is characterized by its durable material composition, typically made from high-quality metals or synthetic materials that can withstand the high temperatures and pressures within the engine compartment. Its design includes features such as reinforced connections and precise diameter sizing to ensure a secure fit and efficient oil flow. Additionally, the tube may incorporate unique characteristics like anti-corrosion coatings or vibration dampening elements to enhance its performance and longevity 3.

Benefits

The use of the Lubricating Oil Supply Tube offers several benefits, including improved engine lubrication which leads to reduced friction and wear on engine components. This results in enhanced durability and contributes to the overall efficiency of the engine. By ensuring a consistent supply of oil, the tube helps maintain engine performance, potentially leading to lower maintenance costs and extended engine life 4.

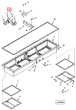

Installation and Integration

Proper installation of the Lubricating Oil Supply Tube within the engine system is crucial for its effective operation. Guidelines for installation include ensuring a secure fit within the engine’s oil passages, verifying the alignment of connections to prevent leaks, and confirming that the tube is free from obstructions. Specific considerations may include the use of compatible sealants or gaskets to ensure a leak-free connection, and adhering to manufacturer recommendations for torque specifications when tightening connections 5.

Maintenance and Troubleshooting

Maintaining the Lubricating Oil Supply Tube involves regular inspection procedures to check for signs of wear, leaks, or obstructions. Common issues to watch for include oil leaks at connections, blockages within the tube, or signs of corrosion. Troubleshooting tips may include cleaning the tube and connections, replacing worn or damaged sections, and ensuring that all connections are tight and secure. Regular maintenance helps ensure optimal performance and longevity of the lubrication system 6.

Manufacturer - Cummins

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality and expertise in producing reliable engine components. With a strong reputation for innovation and durability, Cummins components are designed to meet the demanding requirements of heavy-duty applications. Their Lubricating Oil Supply Tube exemplifies their dedication to enhancing engine performance and reliability through precision engineering and high-quality materials 7.

Cummins Engine Compatibility with Lubricating Oil Supply Tube Part 4001258

The Cummins Lubricating Oil Supply Tube part number 4001258 is designed to fit seamlessly within a range of Cummins engine models. This part is crucial for maintaining the proper flow of lubricating oil, ensuring the engine operates efficiently and reliably.

QSK45 CM500 and QSK60 CM500

The QSK45 CM500 and QSK60 CM500 engines share a similar design in terms of their oil supply systems. The part 4001258 is engineered to fit these models, providing a reliable connection for the lubricating oil supply. This ensures that both engines receive the necessary lubrication to maintain optimal performance.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine, while part of the same family, incorporates more advanced features and specifications. The lubricating oil supply tube part 4001258 is specifically designed to meet the unique requirements of this model, ensuring compatibility and performance.

QSK60G

The QSK60G engine represents a more recent iteration in the Cummins lineup. The part 4001258 is tailored to fit this model, providing a precise and reliable oil supply. This ensures that the QSK60G engine maintains its high standards of efficiency and durability.

Role of Part 4001258 Lubricating Oil Supply Tube in Engine Systems

The 4001258 Lubricating Oil Supply Tube is a critical component in the lubrication system of an engine, facilitating the efficient distribution of oil to various engine parts. This tube connects the oil pan to other critical components, ensuring a steady and reliable flow of lubricating oil.

Integration with the Oil Pan

The oil pan serves as the reservoir for the engine’s lubricating oil. The 4001258 tube draws oil from the pan and channels it to the engine’s lubrication points. This connection is vital for maintaining the oil level and pressure required for optimal engine performance. The tube’s design allows for minimal resistance, ensuring that oil is pumped efficiently from the pan to the rest of the system 8.

Ensuring Consistent Oil Flow

As the oil is drawn from the pan, the 4001258 tube plays a role in maintaining a consistent flow rate. This is important for the proper lubrication of moving parts such as the crankshaft, camshaft, and pistons. The tube’s precise engineering helps prevent blockages and ensures that oil reaches these components without interruption, reducing wear and tear on the engine 9.

Supporting Engine Longevity

By ensuring a reliable oil supply, the 4001258 tube contributes to the overall longevity of the engine. Proper lubrication minimizes friction between metal parts, which can lead to overheating and premature wear. The tube’s role in this process is subtle yet significant, as it supports the engine’s ability to operate smoothly over extended periods 10.

Facilitating Maintenance

The design of the 4001258 tube also aids in maintenance procedures. Its placement and connections are typically accessible, allowing mechanics to easily inspect and replace the tube if necessary. This accessibility is beneficial for routine checks and ensures that the lubrication system remains in top condition 11.

Conclusion

In summary, the 4001258 Lubricating Oil Supply Tube is a key component in the engine’s lubrication system, working in tandem with the oil pan to deliver consistent and efficient oil flow to critical engine parts. Its role in supporting engine performance and longevity cannot be overstated.

-

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021677.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021677.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021677.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021677.

↩ -

Pulkrabek, W. W. (2014). Engineering Fundamentals of the Internal Combustion Engine. Pearson Education.

↩ -

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 4021677.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.