This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

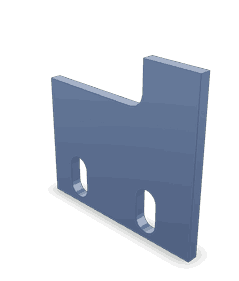

The Cummins Oil Baffle Plate, part number 4001199, is a component designed to enhance the operation of heavy-duty trucks. This part is integral to maintaining the efficiency and reliability of the engine. Cummins, a well-regarded manufacturer in the automotive industry, produces this baffle plate with a focus on quality and performance 2.

Basic Concepts of an Oil Baffle Plate

An oil baffle plate is a device installed within the oil pan of an engine. Its function is to reduce the movement of oil during operation, which can otherwise lead to inefficient lubrication and increased wear on engine components. By stabilizing the oil, the baffle plate allows for consistent lubrication, which is vital for the smooth operation of the engine 3.

Purpose of the Oil Baffle Plate

The Oil Baffle Plate is designed to contribute to the lubrication system of a truck’s engine. It plays a role in maintaining a stable oil level within the pan, which ensures that the oil pump can effectively draw oil for circulation throughout the engine. This stability is particularly important during acceleration, deceleration, and cornering, where oil movement can be more pronounced 1.

Key Features

This Cummins part is constructed from durable materials that can withstand the high temperatures and pressures within an engine. Its design includes specific contours and ridges that are engineered to direct oil flow and reduce turbulence. These features enhance the plate’s ability to perform under various driving conditions 4.

Benefits

The installation of the Oil Baffle Plate can lead to improved engine efficiency by ensuring that oil is consistently available for lubrication. It also helps in reducing oil slosh, which can prevent oil starvation in certain parts of the engine. Additionally, the durable construction of the baffle plate contributes to its longevity and reliability in demanding environments 2.

Installation Process

To install the Oil Baffle Plate, one should begin by ensuring the engine is cool and the oil has been drained from the oil pan. The old baffle plate, if present, should be removed. The new baffle plate should be positioned according to the manufacturer’s instructions, ensuring it is correctly aligned with the oil pump pickup tube. Secure the baffle plate in place using the appropriate fasteners, and then refill the oil pan with the recommended grade and quantity of oil 1.

Maintenance Tips

To maintain the Oil Baffle Plate, it is advisable to inspect it during regular oil changes. Look for signs of wear or damage that could affect its performance. Cleaning the baffle plate with a suitable solvent can remove any contaminants that may have accumulated. Ensuring that the correct oil level and type are used will also contribute to the longevity of the baffle plate 2.

Troubleshooting Common Issues

Common issues with the Oil Baffle Plate may include oil leaks or a reduction in its effectiveness over time. If an oil leak is detected, it is important to check the baffle plate for any signs of damage or improper installation. A reduction in effectiveness may be addressed by inspecting the baffle plate for wear and ensuring that it is correctly positioned within the oil pan 1.

Cummins: Manufacturer Overview

Cummins is a manufacturer with a long-standing reputation for producing high-quality automotive components. The company has a history of innovation and a commitment to excellence in the industry. Cummins’ products, including the Oil Baffle Plate, are designed with a focus on durability, performance, and compatibility with a wide range of heavy-duty truck engines 2.

Application in Cummins Engines

QSK45 CM500 and QSK60 CM500

In the QSK45 CM500 and QSK60 CM500 engines, the Oil Baffle Plate plays a pivotal role in maintaining the integrity of the lubrication system. These engines are known for their robust design and high performance, and the Oil Baffle Plate ensures that the oil is distributed evenly and efficiently throughout the engine. This helps in reducing wear and tear, maintaining optimal engine performance, and extending the engine’s lifespan 2.

QSK60 CM850 MCRS

The QSK60 CM850 MCRS engine, which is part of the Cummins QSK60 series, also utilizes the Oil Baffle Plate. This engine is designed for heavy-duty applications and is equipped with advanced features to handle demanding conditions. The Oil Baffle Plate in this engine ensures that the oil is directed correctly, preventing oil starvation in high-stress areas and maintaining consistent lubrication across all engine components. This is crucial for the engine’s reliability and efficiency, especially in high-performance and heavy-duty operations 2.

Role of Part 4001199 Oil Baffle Plate in Engine Systems

The Oil Baffle Plate is an integral component in maintaining the efficiency and performance of engine systems, particularly in relation to the housing and flywheel.

Within the engine housing, the Oil Baffle Plate is positioned to manage the flow of oil, ensuring that it is directed to the necessary components without causing turbulence or spillage. This controlled oil flow is essential for the lubrication of moving parts, which in turn reduces friction and wear. The baffle plate helps in maintaining a stable oil level within the housing, which is vital for the consistent operation of the engine 3.

In conjunction with the flywheel, the Oil Baffle Plate plays a significant role in the lubrication process. The flywheel, a rotating mechanical device that stores rotational energy, requires precise lubrication to function smoothly. The baffle plate ensures that oil is evenly distributed to the flywheel, preventing excessive wear and tear. This consistent lubrication is key to the flywheel’s ability to maintain momentum and deliver power efficiently to the engine’s moving parts 4.

Conclusion

The Oil Baffle Plate, part number 4001199, is a critical component in the engine’s lubrication system. Its role in managing oil flow and maintaining a stable oil level is essential for the efficient operation and longevity of heavy-duty truck engines. Proper installation, maintenance, and troubleshooting of this part are crucial for ensuring optimal engine performance and reliability.

-

Taghavifar, Hamid, and Aref Mardani. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ ↩ ↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ ↩ ↩ ↩ ↩ ↩ -

Boger, Thorsten, and Willard Cutler. Reducing Particulate Emissions in Gasoline Engines. SAE International, 2018.

↩ ↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.