This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

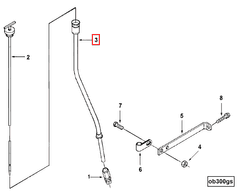

The Cummins 4000608 Oil Gauge Tube is a component designed for use in commercial trucks, specifically within the engine’s lubrication system. Its purpose is to facilitate the accurate measurement and monitoring of oil levels, which is vital for maintaining optimal engine performance and longevity. The significance of this part lies in its ability to provide real-time data on oil levels, allowing for timely maintenance and reducing the risk of engine damage due to insufficient lubrication 1.

Function and Operation

This Cummins part operates as part of the engine’s lubrication system. It is responsible for conveying oil level information from the engine’s oil sump to the oil gauge on the dashboard. This is achieved through a simple yet effective mechanism where the tube is submerged in the oil, and as the oil level changes, so does the level within the tube. This change is then transmitted to the gauge, providing the driver with an accurate reading of the current oil level. This role is fundamental in ensuring that the engine receives adequate lubrication, which is necessary for reducing friction and wear on moving parts 2.

Key Features

The 4000608 is constructed with specific design and material considerations to enhance its performance and durability. It is typically made from high-quality materials that are resistant to corrosion and the high temperatures found within an engine environment. The tube’s dimensions are engineered to fit precisely within the engine’s oil sump, ensuring accurate oil level readings. Additionally, the design may include features such as reinforced ends to prevent damage during installation and use 3.

Benefits

This part offers several advantages. It provides improved accuracy in oil level readings, which is crucial for maintaining the engine’s lubrication system. This accuracy contributes to enhanced engine protection by ensuring that oil levels are maintained within the optimal range, thereby reducing the risk of engine damage due to insufficient lubrication. Furthermore, by facilitating timely maintenance, the tube contributes to overall engine efficiency and longevity 4.

Installation and Compatibility

Proper installation of the Oil Gauge Tube is critical for its effective operation. Installation guidelines typically include ensuring the tube is correctly positioned within the engine’s oil sump and securely connected to the oil gauge. Specific requirements may vary depending on the engine model, so it is important to consult the manufacturer’s instructions for detailed guidance. Compatibility with various engine models and systems is a key consideration, ensuring that the tube functions correctly within the intended application 5.

Maintenance and Troubleshooting

Routine maintenance of the Oil Gauge Tube is important for ensuring its optimal performance. This may include regular checks for signs of wear or damage, ensuring the tube is securely connected, and verifying the accuracy of the oil level readings. Common issues that may arise include inaccurate readings, which could be due to blockages within the tube or damage to the gauge. Troubleshooting steps may involve cleaning the tube, checking connections, or replacing the tube if damage is detected 6.

Safety Considerations

When working with the Oil Gauge Tube, it is important to follow safety precautions and guidelines. This includes ensuring the engine is cool before attempting any maintenance or installation procedures to avoid burns from hot surfaces or oil. Additionally, handling the tube with care to avoid damage is crucial, as is following all manufacturer-recommended procedures for installation and maintenance 7.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product offerings and focus on sustainability and efficiency make it a preferred choice for commercial vehicle operators and manufacturers 8.

Conclusion

In summary, the Cummins 4000608 Oil Gauge Tube is a vital component in the engine’s lubrication system, ensuring accurate oil level readings and contributing to the engine’s overall health and efficiency. Its design, benefits, and the importance of proper installation and maintenance highlight the critical role it plays in engine operation and longevity.

-

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Automotive Service: Inspection, Maintenance, Repair: 2nd Edition, Tim Gilles, Cengage Learning, 2020.

↩ -

Modern Diesel Technology: Light Duty Diesels, Sean Bennett, Cengage Learning, 2012.

↩ -

Engine 15N CM2380 M105B, Bulletin Number 5659770, Fault Code Troubleshooting Manual.

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010.

↩ -

Automotive Service: Inspection, Maintenance, Repair: 2nd Edition, Tim Gilles, Cengage Learning, 2020.

↩ -

Modern Diesel Technology: Light Duty Diesels, Sean Bennett, Cengage Learning, 2012.

↩ -

Engine 15N CM2380 M105B, Bulletin Number 5659770, Fault Code Troubleshooting Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.