This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

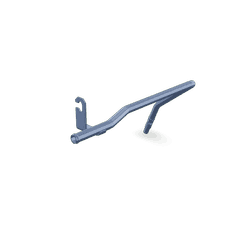

The Lubricating Oil Drain Tube, part number 3990150, is a component manufactured by Cummins, a prominent entity in diesel engine technology. This tube is instrumental in the maintenance routines of heavy-duty trucks, facilitating the efficient draining of used lubricating oil from the engine. Regular oil changes are essential for maintaining engine health, and the Lubricating Oil Drain Tube is designed to simplify this process, ensuring it is both effective and straightforward.

Function and Operation

The Lubricating Oil Drain Tube operates by providing a pathway for used oil to exit the engine during an oil change. This component is integral to the oil change process, allowing for the complete and efficient removal of old oil, which is necessary to maintain optimal engine performance. Regular oil changes help remove contaminants and degraded products from the oil, which can otherwise lead to engine wear and reduced efficiency 1.

Key Features

Characterized by its robust design and material selection, the Lubricating Oil Drain Tube is tailored to withstand the demanding conditions of heavy-duty truck applications. Made from high-quality materials, this tube is resistant to corrosion and high temperatures, ensuring durability and reliability over time. Its design may include features such as a secure fitting mechanism to prevent leaks and a smooth interior to facilitate the flow of oil 2.

Benefits of Using the Lubricating Oil Drain Tube

Incorporating the Lubricating Oil Drain Tube into truck maintenance routines offers several advantages. It contributes to improved engine performance by ensuring that oil changes are conducted efficiently and completely. This, in turn, helps extend the engine’s life by maintaining clean and effective lubrication. Additionally, the design of the tube simplifies the oil change procedure, making it quicker and easier for maintenance personnel 3.

Installation and Maintenance Tips

For the proper installation of the Lubricating Oil Drain Tube, it is important to follow manufacturer guidelines to ensure a secure and leak-free connection. Regular maintenance practices, such as inspecting the tube for signs of wear or damage and ensuring all connections are tight, can help ensure its longevity. It is also beneficial to clean the area around the tube after each use to prevent the buildup of dirt or debris that could affect its performance.

Troubleshooting Common Issues

Frequent problems associated with the Lubricating Oil Drain Tube may include leaks or blockages. To address leaks, it is important to check all connections for tightness and inspect the tube for any signs of damage. Blockages can often be resolved by ensuring that the tube is clear of any obstructions and that the oil is flowing freely. Regular maintenance and inspections can help identify and resolve these issues before they lead to more significant problems.

Safety Considerations

When working with the Lubricating Oil Drain Tube, it is important to follow safety protocols to protect against burns from hot oil and to ensure the proper disposal of used lubricants. Always allow the engine to cool before attempting an oil change, and use appropriate personal protective equipment. Used oil should be disposed of in accordance with local regulations to protect the environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to sustainability, Cummins has established itself as a trusted provider of reliable and efficient power solutions for various industries, including transportation, construction, and power generation.

Compatibility of Cummins Lubricating Oil Drain Tube (Part 3990150)

The Cummins Lubricating Oil Drain Tube, part number 3990150, is designed to facilitate the drainage of used oil from the engine’s sump. This part is integral to maintaining engine health by ensuring that old, contaminated oil is efficiently removed, allowing for the introduction of fresh oil that enhances lubrication and reduces wear.

Application in Cummins Engines

The 3990150 oil drain tube is compatible with several Cummins engine models, ensuring a standardized fit across different engine types. Here are the specific engines and engine groups where this part is applicable:

-

QSB5.9 44 CM550: This engine model is part of the QSB series, known for its robust design and reliability in various industrial applications. The 3990150 oil drain tube is engineered to fit seamlessly within the QSB5.9 44 CM550, ensuring optimal oil drainage and maintaining the engine’s performance.

-

QSC6.7 44 CM550: Another member of the QSC series, the QSC6.7 44 CM550 benefits from the 3990150 oil drain tube. This part ensures that the oil drainage process is efficient, contributing to the engine’s longevity and efficiency.

-

QSK19 44 CM550: The QSK19 44 CM550 is a high-performance engine designed for demanding applications. The 3990150 oil drain tube is specifically designed to fit this engine model, ensuring that the oil drainage system operates smoothly and effectively.

-

QSK38 44 CM550: This engine model, part of the QSK series, is engineered for heavy-duty applications. The 3990150 oil drain tube is a crucial component in this engine, facilitating the efficient removal of used oil and contributing to the engine’s overall reliability and performance.

By ensuring that the 3990150 oil drain tube is correctly installed in these engines, users can maintain the integrity of their engine’s lubrication system, leading to improved performance and longevity.

Role of Part 3990150 Lubricating Oil Drain Tube in Engine Systems

The lubricating oil drain tube, part number 3990150, is a critical component in the maintenance and operation of engine systems. Its primary function is to facilitate the efficient drainage of lubricating oil from the crankcase, ensuring that the oil can be regularly changed or inspected without causing undue stress on the engine components.

Integration with the Crankcase

The crankcase is a vital part of the engine, housing the crankshaft and connecting rods. It also serves as a reservoir for the engine’s lubricating oil. The lubricating oil drain tube is strategically positioned to connect to the lower part of the crankcase. This allows for the straightforward removal of used oil, which is necessary for maintaining the viscosity and cleanliness of the oil, thereby prolonging the life of the engine components.

Interaction with the Breather System

In conjunction with the breather system, the lubricating oil drain tube plays a supportive role in maintaining the overall health of the engine. The breather system is designed to allow air to escape from the crankcase as the crankshaft rotates, preventing the buildup of pressure that could lead to oil leaks or other issues. By ensuring that the crankcase is properly ventilated, the breather system works in tandem with the drain tube to keep the engine environment stable and conducive to optimal performance.

Maintenance and Operational Efficiency

Regular drainage of lubricating oil is essential for the operational efficiency of the engine. The lubricating oil drain tube simplifies this process, allowing mechanics and engineers to perform maintenance tasks with greater ease and precision. This, in turn, helps in identifying potential issues early, such as contamination or degradation of the oil, which could otherwise lead to more significant problems if left unchecked.

Conclusion

In summary, the lubricating oil drain tube (part 3990150) is a key component in the maintenance routine of engine systems, working in harmony with the crankcase and breather system to ensure the engine operates smoothly and efficiently. Regular maintenance and proper installation of this part are crucial for maintaining engine health and performance.

-

BT Fijalkowski. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Robert Fischer, Ferit Kucukay, Gunter Jurgens, Rolf Najork, and Burkhard Pollak. The Automotive Transmission Book Powertrain. Springer, 2015.

↩ -

Robert Bosch GmbH. Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition. Springer Vieweg, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.