This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

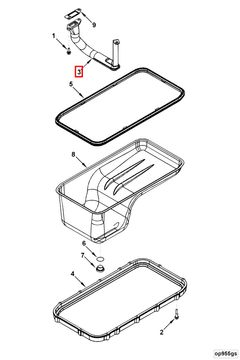

The Lubricating Oil Suction Tube, identified by Part #3978189, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This tube is integral to the engine lubrication system, ensuring that oil is efficiently drawn from the oil pan and circulated throughout the engine. Cummins is renowned for its commitment to quality and innovation, making this component a reliable choice for maintaining optimal engine performance 1.

Function and Operation

The Lubricating Oil Suction Tube operates by facilitating the movement of oil from the oil pan to the engine’s lubrication system. It connects to the oil pump, allowing for consistent oil flow that is vital for lubricating moving parts within the engine. This continuous circulation helps in reducing friction between components, which is crucial for maintaining engine efficiency and preventing premature wear 2. The tube’s design ensures that oil is drawn smoothly, contributing to the overall reliability and performance of the engine.

Key Features

The Lubricating Oil Suction Tube is engineered with precision, featuring a robust construction that includes high-quality materials resistant to corrosion and wear. Its dimensions are meticulously designed to fit seamlessly within the engine compartment, ensuring a secure and efficient connection to the oil pump. The tube’s smooth interior surface minimizes turbulence in the oil flow, enhancing the lubrication process. Additionally, its durable construction supports long-term use under varying operating conditions 3.

Benefits

Incorporating the Lubricating Oil Suction Tube into the engine lubrication system offers several advantages. It contributes to improved engine lubrication by ensuring a steady supply of oil to critical components. This consistent lubrication reduces friction and wear on engine parts, potentially leading to enhanced fuel efficiency. Furthermore, by maintaining optimal lubrication, the tube plays a role in prolonging the engine’s lifespan, offering value through extended component durability and reliability 4.

Installation and Maintenance

Proper installation of the Lubricating Oil Suction Tube is vital for ensuring its effectiveness and longevity. It is recommended to follow manufacturer guidelines closely, ensuring that all connections are secure and that the tube is correctly positioned within the engine compartment. Regular maintenance checks are advised to verify the tube’s condition, looking for signs of wear, leaks, or blockages. Cleaning the area around the tube and inspecting it during routine oil changes can help in identifying potential issues early, ensuring continued optimal performance.

Troubleshooting Common Issues

Common issues associated with the Lubricating Oil Suction Tube may include leaks, blockages, or malfunctions due to wear or damage. Diagnostic procedures should begin with a visual inspection of the tube and its connections for any visible signs of damage or wear. If a leak is suspected, checking the oil level and looking for oil stains around the tube can confirm the issue. Blockages may be identified by observing changes in engine performance or oil pressure readings. Addressing these issues promptly, whether through cleaning, repair, or replacement, is important for maintaining the efficiency and reliability of the engine lubrication system.

Cummins Overview

Cummins Inc. has a rich history in the automotive industry, known for its innovative solutions and commitment to quality. The company offers a wide range of products, including engines, filtration systems, and aftermarket parts, designed to meet the demanding requirements of various applications. Cummins’ reputation is built on its dedication to customer satisfaction, ensuring that its products not only meet but exceed expectations in performance, durability, and reliability. This commitment is evident in the design and manufacturing of components like the Lubricating Oil Suction Tube, underscoring Cummins’ role as a leader in the industry.

Lubricating Oil Suction Tube (Part 3978189) Compatibility with Cummins Engines

The Cummins part 3978189, a Lubricating Oil Suction Tube, is designed to fit into several of Cummins’ engine models. This part is integral to the engine’s lubrication system, ensuring that oil is properly drawn from the oil pan and circulated throughout the engine to maintain optimal performance and longevity.

ISB/ISD4.5 CM2150 B119

The ISB/ISD4.5 CM2150 B119 engine is one of the models that can utilize the 3978189 oil suction tube. This engine is known for its robust construction and reliability, often used in heavy-duty applications.

ISBE CM800

The ISBE CM800 engine is another model that is compatible with the 3978189 oil suction tube. This engine is typically used in industrial and marine applications, providing a balance of power and efficiency.

ISBE4 CM850 and QSB4.5 CM850 (CM2850)

Both the ISBE4 CM850 and the QSB4.5 CM850 (CM2850) engines can also use the 3978189 oil suction tube. These engines are known for their versatility and are often found in a variety of applications, from construction equipment to agricultural machinery. The ISBE4 CM850 is particularly noted for its high torque output, while the QSB4.5 CM850 (CM2850) is recognized for its durability and efficiency.

Grouping of Engines

The compatibility of the 3978189 oil suction tube across the ISB/ISD4.5 CM2150 B119, ISBE CM800, ISBE4 CM850, and QSB4.5 CM850 (CM2850) engines highlights the part’s versatility and importance in maintaining the lubrication systems of these engines. This compatibility ensures that technicians and operators can rely on a single part for multiple engine models, simplifying maintenance and inventory management.

Conclusion

The Lubricating Oil Suction Tube, part number 3978189, is a critical component in the efficient operation of Cummins engines’ lubrication systems. By ensuring a consistent and reliable flow of oil from the oil pan to the oil pump, this Cummins part plays a significant role in reducing friction, preventing wear, and maintaining the overall performance and longevity of the engine. Its compatibility with various Cummins engine models underscores its versatility and importance in engine maintenance and operation.

-

Halderman, J. D. (2012). Automotive Principles: Diagnosis and Service. Prentice Hall.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Schneider, W.-H. (2016). Pistons and Engine Testing. Springer Nature.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.