This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

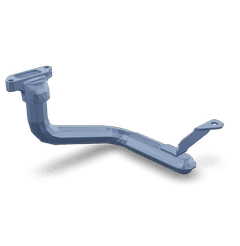

The Oil Suction Connection 3976770, a component designed by Cummins for use in heavy-duty trucks, is integral to the lubrication system of truck engines. This part ensures that oil is efficiently drawn from the sump and circulated throughout the engine to maintain optimal performance and longevity.

Basic Concepts of Oil Suction Connection

An oil suction connection is a fitting that allows oil to be drawn from the oil sump and delivered to the engine’s lubrication system. This process is vital for maintaining engine health, as it ensures that all moving parts receive the necessary lubrication to reduce friction, wear, and heat. The Oil Suction Connection plays a role in this system by providing a secure and efficient pathway for oil to travel from the sump to the engine 1.

Purpose of the 3976770 Oil Suction Connection

The 3976770 is designed to facilitate the flow of oil from the sump to the engine. It ensures that the oil pump can draw oil effectively, which is then circulated through the engine to lubricate critical components. This part contributes to maintaining the engine’s operational efficiency and protecting it from damage due to insufficient lubrication.

Key Features

The 3976770 is characterized by its robust design and the materials used in its construction. It is made from high-quality materials that offer resistance to corrosion and wear, ensuring durability in the demanding environment of a heavy-duty truck engine. The design of this connection is tailored to provide a secure fit and efficient oil flow, enhancing the overall performance of the lubrication system.

Benefits

Utilizing the 3976770 offers several advantages. It contributes to improved engine lubrication, which is crucial for reducing friction and wear on engine components. The enhanced durability of this part ensures long-term reliability, and its efficient design may contribute to overall engine efficiency by ensuring consistent oil flow.

Installation Process

Installing the 3976770 requires careful attention to detail to ensure a secure and effective fit. Preparatory steps include cleaning the installation area and ensuring that all mating surfaces are free of debris. The necessary tools for installation may vary, but typically include wrenches and possibly a torque wrench to ensure proper tightening. Following the manufacturer’s guidelines for torque specifications is important to avoid over-tightening, which could damage the connection, or under-tightening, which could lead to leaks.

Troubleshooting and Maintenance

Common issues with the 3976770 may include leaks or blockages, which can affect the efficiency of the lubrication system. Troubleshooting these issues involves checking for proper installation, ensuring there are no obstructions in the oil path, and verifying that all connections are secure. Regular maintenance practices, such as inspecting the connection for signs of wear or corrosion and ensuring it remains clean and free of debris, can help ensure longevity and optimal performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and performance in the commercial truck industry. The company’s product range includes a variety of engines and components designed to meet the demanding requirements of heavy-duty applications.

Role of Part 3976770 Oil Suction Connection in Engine Systems

The 3976770 is an integral component in the lubrication system of an engine, facilitating the efficient circulation of oil to ensure optimal engine performance and longevity. This component interfaces directly with the oil pan and plays a significant role in the oil suction process.

Interaction with the Oil Pan

The Oil Suction Connection is designed to fit securely into the oil pan, which serves as the reservoir for the engine’s lubricant. The connection point ensures a tight seal, preventing any oil leaks that could lead to insufficient lubrication and potential engine damage.

Oil Suction Process

Once the Oil Suction Connection is in place, it allows the oil pump to draw oil from the pan effectively. The oil is then transported through the engine’s lubrication circuits, coating moving parts such as bearings, pistons, and camshafts. This continuous circulation is essential for reducing friction, dissipating heat, and removing contaminants from the engine’s internal components.

Ensuring Efficient Lubrication

The design of the Oil Suction Connection ensures that oil is drawn from the pan consistently, even when the engine is operating at high RPMs or when the vehicle is on an incline. This stability in oil suction is vital for maintaining a consistent oil pressure throughout the engine, which is necessary for the reliable operation of all lubricated parts.

Integration with Other Components

While the primary role of the Oil Suction Connection is to interface with the oil pan, its effective function also relies on its integration with other components such as the oil pump and filtration system. A well-designed suction connection contributes to the overall efficiency of the lubrication system, ensuring that clean, pressurized oil is always available to the engine’s critical components.

Conclusion

The 3976770 Oil Suction Connection by Cummins is a critical component in the lubrication system of heavy-duty truck engines. Its robust design, efficient oil flow capabilities, and integration with the engine’s lubrication system contribute to the engine’s overall performance, longevity, and reliability. Proper installation, maintenance, and troubleshooting are essential to ensure the optimal functioning of this part and, by extension, the engine it serves.

-

Heavy Duty Truck Systems, Fifth Edition, by Sean Bennett and Ian Andrew Norman, Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.