This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3930338 Lubricating Oil Pump is essential for the operation of commercial trucks. It ensures that engine components receive adequate lubrication, which is fundamental for maintaining engine efficiency and longevity. This part plays a significant role in the overall performance and reliability of the truck’s engine.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump circulates oil throughout an engine, ensuring that all moving parts are adequately lubricated. This process reduces friction, wear, and heat generation within the engine. Proper lubrication is fundamental to the longevity and performance of engine components, as it helps to minimize wear and tear and maintain operational efficiency 1.

Purpose of the Cummins 3930338 Lubricating Oil Pump

The Cummins 3930338 Lubricating Oil Pump is specifically engineered to maintain consistent oil flow within the engine. It ensures that oil is delivered to critical components such as bearings, pistons, and camshafts. By maintaining proper lubrication, this pump helps to enhance engine performance, reduce the risk of mechanical failure, and contribute to the overall reliability of the truck.

Key Features

The Cummins 3930338 Lubricating Oil Pump is characterized by its robust design and the use of high-quality materials. It features a durable construction that can withstand the demanding conditions of commercial truck operations. Additionally, the pump is designed with precision to ensure efficient oil circulation and consistent performance. Unique characteristics include its compatibility with various engine types and its ability to operate effectively under different conditions.

Benefits

Utilizing the Cummins 3930338 Lubricating Oil Pump offers several advantages. It contributes to improved engine performance by ensuring that all components are properly lubricated. This results in reduced friction and wear, leading to enhanced engine longevity. Additionally, the pump’s reliable operation helps to maintain the overall reliability of the truck, reducing the likelihood of unexpected downtime.

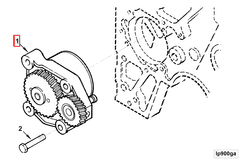

Installation Process

Installing the Cummins 3930338 Lubricating Oil Pump involves several steps. First, ensure that the engine is clean and free of debris. Next, align the pump with the engine’s oil passages and secure it in place using the appropriate fasteners. It is important to follow the manufacturer’s instructions carefully to ensure proper installation. Tools required may include wrenches, sockets, and possibly a torque wrench to ensure fasteners are tightened to the correct specifications.

Maintenance Tips

To ensure optimal performance and longevity of the Cummins 3930338 Lubricating Oil Pump, regular maintenance is recommended. This includes checking for any signs of wear or damage, ensuring that all connections are secure, and verifying that the pump is operating within specified parameters. Additionally, adhering to recommended servicing intervals for oil changes and filter replacements will help maintain the pump’s efficiency.

Troubleshooting Common Issues

Common issues with the Cummins 3930338 Lubricating Oil Pump may include inadequate oil pressure, leaks, or unusual noises during operation. To address these issues, first, verify that the pump is properly installed and that all connections are secure. Check for any signs of wear or damage to the pump or its components. If issues persist, consulting the manufacturer’s troubleshooting guide or seeking professional assistance may be necessary.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engines and components, Cummins has established a strong reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry 2.

Cummins Engine Compatibility with Lubricating Oil Pump Part 3930338

The Cummins lubricating oil pump part number 3930338 is designed to fit a range of Cummins engines, ensuring efficient oil circulation and engine performance. Below is a detailed description of its compatibility with various engine models:

6C8.3

The 6C8.3 engine is one of the models that can utilize the 3930338 oil pump. This part is engineered to meet the specific oil flow requirements of the 6C8.3 engine, ensuring optimal lubrication and engine longevity.

C GAS PLUS CM556

The C GAS PLUS CM556 engine is another model compatible with the 3930338 oil pump. This part is tailored to provide the necessary oil pressure and flow for the CM556 variant, ensuring smooth engine operation and reliability.

C8.3 G and G8.3

Both the C8.3 G and G8.3 engines are designed to work seamlessly with the 3930338 oil pump. This part is specifically engineered to fit these engines, providing the required lubrication to maintain engine health and performance.

Grouping of Engines

The engines listed above, 6C8.3, C GAS PLUS CM556, C8.3 G, and G8.3, share a commonality in their compatibility with the 3930338 oil pump. This part is designed to fit these engines, ensuring they receive the proper lubrication needed for efficient operation. The compatibility of the 3930338 oil pump with these engines underscores its versatility and importance in maintaining engine performance across different models.

Role of Part 3930338 Lubricating Oil Pump in Engine Systems

The lubricating oil pump, identified by part number 3930338, is integral to maintaining the health and efficiency of various engine systems. Its primary function is to circulate lubricating oil throughout the engine, ensuring all moving parts are adequately coated to reduce friction and wear.

Integration with Cylinder Block

Within the cylinder block, the lubricating oil pump ensures that the crankshaft, connecting rods, and pistons receive a continuous supply of oil. This lubrication is essential for minimizing metal-to-metal contact, which can lead to excessive wear and potential engine failure.

Role in Long Block Assembly

In a long block configuration, which includes the cylinder block, crankshaft, pistons, and other essential components, the lubricating oil pump is vital. It guarantees that all internal components, such as the camshaft and valve train, are properly lubricated. This consistent oil flow helps in maintaining optimal engine performance and longevity.

Lubricating Pump Kit Applications

When utilizing a lubricating pump kit, part 3930338 plays a central role. The kit typically includes various gaskets, seals, and the pump itself. The pump ensures that oil is efficiently distributed to all critical areas, enhancing the overall reliability of the engine system.

Short Block 6-Cart and Short Engine Kit

In both the short block 6-cart and short engine kit, the lubricating oil pump is a key component. These configurations usually consist of the cylinder block, crankshaft, pistons, and connecting rods. The pump ensures that these parts are well-lubricated, which is essential for smooth operation and durability.

General Engine Systems

Across various engine systems, the lubricating oil pump maintains a steady oil pressure, which is monitored by the oil pressure sensor. This pressure is crucial for the proper functioning of the oil filter, which removes contaminants from the oil, ensuring that only clean lubricant reaches the engine components.

Conclusion

In summary, the Cummins 3930338 Lubricating Oil Pump is a fundamental component in ensuring the efficient and reliable operation of engine systems by providing consistent lubrication to all moving parts. Its robust design, compatibility with various engine models, and essential role in engine performance make it a critical part for commercial truck operations.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.