This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

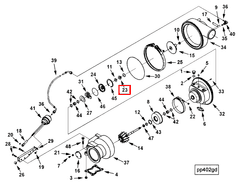

The Cummins 3531916 Oil Slinger is a component designed to enhance the lubrication system in heavy-duty trucks. Its purpose is to ensure that oil is effectively distributed throughout the engine, contributing to the smooth operation and longevity of the vehicle.

Basic Concepts of an Oil Slinger

An oil slinger is a device used in engines to help distribute lubrication. It operates by spinning with the engine’s components, flinging oil outward to coat moving parts. This mechanism is vital for maintaining proper lubrication, which reduces friction and wear on engine components 1.

Purpose of the Cummins 3531916 Oil Slinger

The Cummins 3531916 Oil Slinger plays a specific role in the engine’s lubrication system by aiding in the distribution of oil to various moving parts. This ensures that all components receive adequate lubrication, which is crucial for minimizing friction and wear, and maintaining optimal engine performance 2.

Key Features

The Cummins 3531916 Oil Slinger is constructed with durable materials to withstand the harsh conditions within an engine. Its design includes specific attachment methods that secure it firmly in place, ensuring it operates effectively. Unique characteristics of this oil slinger may include its shape and size, tailored to fit precisely within the engine’s design 3.

Benefits of Using the Cummins 3531916 Oil Slinger

Utilizing the Cummins 3531916 Oil Slinger offers several advantages. It contributes to improved engine performance by ensuring consistent lubrication. This can lead to reduced wear on engine components, enhancing the overall reliability and lifespan of the engine 4.

Installation Process

Installing the Cummins 3531916 Oil Slinger involves several steps. First, ensure the engine is clean and free of debris. Then, align the oil slinger with its designated location within the engine. Secure it in place using the appropriate fasteners. Tools required may include wrenches and possibly a torque wrench to ensure proper tightening. It’s important to follow the manufacturer’s guidelines to ensure correct installation.

Maintenance and Troubleshooting

Maintaining the Cummins 3531916 Oil Slinger is straightforward but important for its longevity and effectiveness. Regular inspection for signs of wear or damage is recommended. Common issues may include misalignment or damage from debris. Troubleshooting steps involve checking the attachment points for security, ensuring the slinger spins freely, and addressing any signs of wear promptly.

Manufacturer: Cummins

Cummins is a well-regarded name in the engine manufacturing industry, known for its commitment to quality and innovation. With a rich history of producing reliable engine components, Cummins continues to be a leader in providing solutions that enhance engine performance and durability.

Compatibility of Cummins Oil Slinger Part 3531916 with Various Engines

The Cummins Oil Slinger part 3531916 is designed to be compatible with a range of engines, ensuring efficient lubrication and maintenance across multiple engine models. This part is integral to the engine’s operation, providing a reliable method for oil distribution.

Compatible Engines

- GTA38 G CMEICS G116C

- K38

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

- NH/NT 855

- QSK19G

- QSK60 CM500

- QSK60G

- QSK78 CM500

- QSM11 CM570

- QSN14 CM876 N103

- QST30 CM552

These engines, while differing in specifications and applications, share a common requirement for effective oil distribution. The Cummins Oil Slinger part 3531916 meets this requirement, ensuring that each engine operates smoothly and efficiently.

Grouping of Compatible Engines

-

KTA19GC Series:

- KTA19GC

- KTA19GC CM558

- KTA38GC CM558

-

QSK Series:

- QSK19G

- QSK60 CM500

- QSK60G

- QSK78 CM500

-

QSM and QSN Series:

- QSM11 CM570

- QSN14 CM876 N103

-

QST Series:

- QST30 CM552

By grouping these engines, it is evident that the Cummins Oil Slinger part 3531916 is versatile and can be used across a broad spectrum of engine models, facilitating ease of maintenance and repair.

Role of Part 3531916 Oil Slinger in Engine Systems

The part 3531916 Oil Slinger is an essential component in maintaining the lubrication and performance of various engine systems. It ensures that oil is effectively distributed to critical areas, enhancing the efficiency and longevity of the engine.

Integration with Engine Components

-

Aftercooler: The Oil Slinger aids in lubricating the aftercooler, ensuring that the cooling process of the compressed air is efficient and that the aftercooler remains free from excessive wear.

-

Aftermarket Turbocharger: In aftermarket turbochargers, the Oil Slinger plays a significant role in maintaining the lubrication of the turbocharger’s moving parts, which is vital for optimal performance and durability.

-

Camshaft Mounting: Proper lubrication provided by the Oil Slinger is essential for the camshaft mounting system. This ensures smooth operation and reduces friction between the camshaft and its bearings.

-

Connecting Rod: The Oil Slinger helps in delivering oil to the connecting rod, which is subject to high stress and friction. Consistent lubrication is key to preventing wear and ensuring the connecting rod functions smoothly.

-

Core Assembly: Within the core assembly, the Oil Slinger ensures that all moving parts receive adequate lubrication, which is crucial for the assembly’s efficiency and longevity.

-

Core Assembly H3B: Similar to the standard core assembly, the H3B variant benefits from the Oil Slinger’s consistent oil distribution, enhancing its performance and reliability.

-

Core Assembly Heat Exchanger 60 and 60W: These assemblies rely on the Oil Slinger to maintain lubrication in the heat exchanger components, ensuring they operate efficiently and withstand the thermal stresses involved.

-

Core Heat Exchanger 60 and 60W Assembly: The Oil Slinger’s role in these assemblies is to provide consistent lubrication to the heat exchanger components, facilitating efficient heat transfer and reducing the risk of component failure.

-

Cylinder Head: Lubrication of the cylinder head is vital for its performance and longevity. The Oil Slinger ensures that oil reaches the cylinder head, reducing friction and wear on its components.

-

Heat Exchanger 60 Turbocharger: The Oil Slinger is integral in lubricating the heat exchanger within the turbocharger, ensuring that it operates efficiently and maintains its performance over time.

-

Parts and Performance: Overall, the Oil Slinger contributes to the performance of various engine parts by ensuring they are well-lubricated, which is essential for their efficiency and durability.

-

Turbocharger: In turbochargers, the Oil Slinger ensures that all moving parts, including the turbine and compressor, receive adequate lubrication. This is essential for the turbocharger’s performance and longevity.

-

Turbocharger Core: The core of the turbocharger benefits from the Oil Slinger’s lubrication, ensuring that all internal components operate smoothly and efficiently.

-

Turbocharger Kit: When included in a turbocharger kit, the Oil Slinger ensures that all components within the kit are properly lubricated, contributing to the kit’s overall performance and reliability.

Conclusion

This overview provides a comprehensive understanding of the Cummins 3531916 Oil Slinger, its function within heavy-duty truck engines, and the benefits it offers. Proper installation, maintenance, and understanding of its role contribute to the efficient operation of the engine.

-

Minaker, Bruce P. Fundamentals of Vehicle Dynamics and Modelling. John Wiley Sons, 2019.

↩ -

Bennett, Sean. Modern Diesel Technology: Light Duty Diesels. Cengage Learning, 2012.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.