This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3524596 Oil Baffle is a component designed to enhance the operation of commercial trucks by managing oil flow within the engine. Its role is to stabilize oil levels and reduce turbulence, contributing to the overall efficiency and longevity of the engine 1.

Basic Concepts of Oil Baffles

An oil baffle is a device installed within the oil pan of an engine. Its function is to control the movement of oil, ensuring a consistent supply to critical engine components. By reducing turbulence, oil baffles help maintain optimal oil levels, which is vital for effective lubrication and cooling of engine parts 2.

Purpose of the Cummins 3524596 Oil Baffle

The Cummins 3524596 Oil Baffle is specifically engineered to stabilize oil flow and minimize sloshing during vehicle operation. This stabilization ensures that the oil remains in the sump area, providing a steady supply to the engine’s moving parts. By reducing oil movement, the baffle helps in maintaining consistent oil pressure, which is crucial for the engine’s lubrication system 3.

Key Features

The Cummins 3524596 Oil Baffle is characterized by its robust design and the materials used in its construction. It is typically made from durable materials that can withstand the harsh conditions within an engine. The baffle’s design includes strategically placed barriers that effectively channel oil flow, enhancing its performance. Additionally, it is engineered to fit seamlessly within the oil pan, ensuring compatibility with Cummins engines.

Benefits of Using an Oil Baffle

Incorporating an oil baffle into a truck’s engine offers several advantages. It improves engine lubrication by ensuring a consistent oil supply to all moving parts. This consistent lubrication reduces wear on engine components, leading to enhanced engine performance and longevity. Furthermore, by stabilizing oil flow, the baffle contributes to more efficient engine operation.

Installation Considerations

Proper installation of the Cummins 3524596 Oil Baffle is crucial for its effective functioning. It is important to follow manufacturer guidelines to ensure it is correctly positioned within the oil pan. Special tools may be required for installation, and it is advisable to refer to the Cummins installation manual for detailed instructions.

Troubleshooting Common Issues

Common issues associated with oil baffles include oil leaks and reduced engine performance. If an oil leak is detected, it is important to inspect the baffle for any signs of damage or improper installation. Reduced engine performance may indicate insufficient oil supply, which could be due to a malfunctioning baffle. Regular inspections and maintenance can help identify and resolve these issues promptly.

Maintenance Tips

Regular maintenance of the Cummins 3524596 Oil Baffle is important to ensure its continued effectiveness. This includes periodic inspections for signs of wear or damage. Cleaning the baffle as part of routine oil changes can prevent buildup that may affect its performance. If significant wear is observed, replacement may be necessary to maintain optimal engine lubrication.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality and innovation. The company’s products are designed to deliver reliable performance and efficiency, making them a preferred choice for commercial vehicle operators.

Compatibility of Cummins Oil Baffle Part 3524596

The Cummins Oil Baffle part 3524596 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal oil flow and management within the engine’s system. This part is crucial for maintaining the efficiency and longevity of the engine by preventing oil from entering areas where it could cause damage or reduce performance.

Compatible Engines

-

QSK50 CM2150 MCRS and QSK50 CM2350 K108

The Oil Baffle part 3524596 is engineered to integrate smoothly with both the QSK50 CM2150 MCRS and QSK50 CM2350 K108 engines. These engines benefit from the baffle’s precise fit, which helps in maintaining the correct oil levels and preventing oil from splashing into non-designated areas, thus ensuring consistent engine performance and reducing the risk of oil-related failures.

-

QSK95 CM2350 K113

Similarly, the QSK95 CM2350 K113 engine is also compatible with the Cummins Oil Baffle part 3524596. This part is tailored to fit the unique design and requirements of the QSK95 series, providing essential support in managing oil flow and preventing potential issues that could arise from improper oil distribution.

By ensuring a proper fit with these engines, the Oil Baffle part 3524596 plays a vital role in maintaining the overall health and efficiency of the engine, contributing to its reliability and performance.

Role of Part 3524596 Oil Baffle in Engine Systems

The Part 3524596 Oil Baffle is an integral component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers and performance parts. Its primary function is to manage and direct the flow of oil within the turbocharger system, ensuring optimal lubrication and cooling of moving parts.

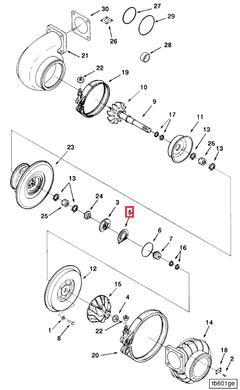

Integration with Aftermarket Turbocharger

When installed in an aftermarket turbocharger, the Oil Baffle helps maintain consistent oil pressure and flow. This is essential for the turbocharger’s core assembly, where precise lubrication is required to reduce friction and wear on the turbine and compressor wheels. The baffle ensures that oil is evenly distributed, which is vital for the longevity and performance of the turbocharger.

Core Assembly and EBM-Parts

In the context of the turbocharger core assembly, the Oil Baffle works in conjunction with EBM-parts to enhance the overall efficiency of the system. By regulating oil flow, it assists in maintaining the temperature of the core components, preventing overheating which can lead to performance degradation or failure. This is particularly important in high-performance applications where the turbocharger is subjected to extreme conditions.

Performance and EBM-Turbocharger

For performance-oriented applications, the integration of the Oil Baffle with EBM-turbochargers is beneficial. It ensures that the turbocharger operates within its optimal temperature range, thereby maximizing efficiency and power output. The baffle’s role in oil management directly contributes to the turbocharger’s ability to handle increased airflow and pressure, which are hallmarks of performance enhancements.

Turbocharger Kit and Parts

When included in a turbocharger kit, the Oil Baffle is a key component that ensures all parts within the kit function harmoniously. It aids in the consistent lubrication of bearings and seals, which are critical for the smooth operation of the turbocharger. This is especially important in high-stress environments where the turbocharger is pushed to its limits.

Overall System Performance

The Part 3524596 Oil Baffle, therefore, plays a significant role in the performance and reliability of engine systems equipped with turbochargers. Its ability to manage oil flow and pressure contributes to the efficient operation of the turbocharger, enhancing both performance and durability. Engineers and mechanics should consider its integration to ensure the turbocharger system operates at peak efficiency.

Conclusion

The Cummins 3524596 Oil Baffle is a critical component for maintaining the efficiency and longevity of Cummins engines. By stabilizing oil flow and ensuring consistent lubrication, this part contributes to the overall performance and reliability of the engine. Proper installation, regular maintenance, and compatibility with specific engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.