This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3519401 Oil Baffle is a component designed to optimize the performance of heavy-duty truck engines. Its primary role is to manage the flow of oil within the engine, ensuring that oil is distributed efficiently and effectively to all necessary parts. This component is integral to maintaining the engine’s longevity and operational efficiency 2.

Basic Concepts of Oil Baffles

An oil baffle is a device installed within the oil pan of an engine. Its function is to control the movement of oil, reducing turbulence and ensuring a steady flow. By managing oil movement, the baffle helps maintain oil quality, preventing aeration and contamination. This, in turn, supports consistent engine performance and protection 1.

Purpose of the 3519401 Oil Baffle

The Cummins 3519401 Oil Baffle is specifically engineered to enhance the oil management system in heavy-duty trucks. It plays a role in directing oil flow, minimizing turbulence within the oil pan. This results in more efficient oil circulation, which is vital for lubricating engine components and dissipating heat 2.

Key Features

The 3519401 Oil Baffle is characterized by its robust design and the materials used in its construction. It is crafted to withstand the demanding conditions within a heavy-duty truck engine. The baffle’s design includes features that enhance its ability to manage oil flow effectively, contributing to its performance 2.

Benefits of Using the 3519401 Oil Baffle

Incorporating the 3519401 Oil Baffle into a truck’s engine system offers several advantages. It improves oil circulation, which is crucial for maintaining engine components’ lubrication. Additionally, it reduces oil aeration, a common issue that can lead to decreased engine performance. The baffle also contributes to enhanced engine protection by ensuring consistent oil flow to critical areas 1.

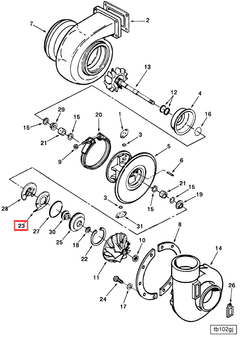

Installation Considerations

Proper installation of the 3519401 Oil Baffle is key to ensuring its effectiveness. This process involves several steps, including preparing the engine compartment, using the appropriate tools, and following a sequence to ensure the baffle is correctly fitted. Attention to these details during installation helps maximize the baffle’s performance and longevity 2.

Troubleshooting Common Issues

Oil baffles, including the 3519401, may encounter issues such as oil leaks or reduced engine performance. These problems can often be traced back to installation errors or wear and tear. Troubleshooting steps may involve inspecting the baffle for damage, ensuring it is correctly installed, and addressing any leaks promptly 2.

Maintenance Tips

Regular maintenance of the 3519401 Oil Baffle is recommended to ensure its continued effectiveness. This includes periodic inspections for signs of wear or damage, cleaning the baffle as needed, and considering replacement if significant deterioration is observed. Adhering to these maintenance practices helps preserve the baffle’s function and the engine’s overall performance 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions across various industries, including automotive and heavy-duty trucking 2.

Compatibility of Cummins Oil Baffle Part 3519401

The Cummins Oil Baffle part number 3519401 is designed to fit seamlessly with a variety of Cummins engine models. This part is integral in maintaining the proper flow and containment of oil within the engine, ensuring optimal performance and longevity 2.

K19 Engines

The K19 engines, known for their robust design and reliability, integrate the Oil Baffle part 3519401 effectively. This part ensures that oil is directed correctly within the engine, preventing oil starvation and reducing wear on critical components 2.

N14 Engines

The N14 engine series, available in both CELECT and MECHANICAL variants, also utilizes the Oil Baffle part 3519401. This part is crucial in maintaining the oil’s path within the engine, ensuring that the lubrication system functions correctly. Whether it is the electronically controlled CELECT version or the mechanically controlled variant, this baffle plays a vital role in the engine’s operation 2.

NH/NT 855 Engines

The NH/NT 855 engines benefit from the Oil Baffle part 3519401, which is engineered to fit these models precisely. This part ensures that oil is directed efficiently, maintaining the engine’s lubrication system integrity and preventing oil from pooling in areas where it could cause damage 2.

QSK38 CM850 MCRS Engines

The QSK38 CM850 MCRS engines also incorporate the Oil Baffle part 3519401. This part is essential in these high-performance engines, ensuring that oil is managed effectively to maintain peak performance and reliability. The baffle’s design allows for optimal oil flow, which is critical in high-stress environments 2.

Role of Part 3519401 Oil Baffle in Engine Systems

The 3519401 Oil Baffle is an integral component in maintaining the efficiency and reliability of various engine systems. It works in conjunction with several key components to ensure optimal performance.

Integration with Core Assemblies

In the Assembly Core and Core Assembly, the oil baffle helps in directing the flow of oil to critical areas, ensuring that all moving parts are adequately lubricated. This is particularly important in the Supercore Assembly 4LGK and Core Assembly H3B, where precise oil distribution is essential for the durability and performance of the engine 2.

Enhancing Camshaft and Cam Follower Housing Performance

When integrated with the Camshaft and Camshaft Right Bank, the oil baffle ensures that these components receive a consistent supply of oil. This is vital for reducing friction and wear, which in turn enhances the longevity and efficiency of the camshaft system. Similarly, in the Cam Follower Housing, the baffle aids in maintaining a stable oil film, which is crucial for smooth operation 2.

Supporting Turbocharger and Injector Systems

In systems involving the EBM-Turbocharger and EBM-Injector, the oil baffle plays a significant role in managing oil flow. It ensures that the turbocharger, whether it is the Turbocharger Core or part of a Turbocharger Kit, receives the necessary lubrication to operate efficiently under high-stress conditions. For the EBM-Injector and Injector Plumbing, the baffle helps in maintaining the integrity of the oil supply, which is essential for precise fuel injection and overall engine performance 2.

Contribution to Cylinder Head and Connecting Rod Systems

The oil baffle also works in tandem with the Cylinder Head and Connecting Rod and Piston assemblies. By ensuring a consistent oil supply to these components, it helps in reducing thermal stress and wear, which are common issues in high-performance engines. This is particularly beneficial in the Cylinder Head, where efficient oil flow is essential for cooling and lubrication 2.

Role in Campaign Kit and Control Kit

In the Campaign Kit and Control Kit, the oil baffle is designed to enhance the reliability of these systems. By ensuring that all components within these kits receive adequate lubrication, it contributes to the overall stability and performance of the engine 2.

Application in Performance Parts

For EBM: Performance Parts and other high-performance components, the oil baffle is essential in maintaining the heightened demands of these systems. It ensures that even under extreme conditions, the engine components remain well-lubricated, thereby enhancing performance and reliability 2.

Conclusion

The 3519401 Oil Baffle is a key component in various engine systems, playing a significant role in ensuring efficient oil distribution and lubrication, which is essential for the optimal performance and longevity of the engine 2.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.