This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3421923 Oil Drain Connection is a component designed for use in heavy-duty trucks. Its purpose is to facilitate the draining of used oil from the engine, playing a role in the routine maintenance of these vehicles. Proper maintenance of the oil system is vital for the longevity and efficiency of heavy-duty truck engines 1.

Basic Concepts of Oil Drain Connections

An oil drain connection is a part of a truck’s lubrication system that allows for the removal of used oil from the engine. This process is fundamental to maintaining engine health, as it ensures that the engine operates with clean oil, which reduces wear and tear on engine components 2. The oil drain connection is typically located at the bottom of the oil pan and is equipped with a plug or valve that can be opened to allow oil to flow out.

Purpose of the Cummins 3421923 Oil Drain Connection

The Cummins 3421923 is specifically designed to aid in the efficient draining of used oil from the engine. By providing a secure and reliable connection point, it ensures that the oil change process is straightforward and minimizes the risk of spills or leaks. This component is integral to the maintenance routine, as it directly contributes to the engine’s lubrication system by allowing for the timely replacement of old oil with new.

Key Features

The Cummins 3421923 is characterized by several key features that enhance its performance and durability. Its design incorporates materials that are resistant to corrosion and high temperatures, ensuring longevity in demanding environments. Additionally, the connection is engineered to provide a tight seal, which prevents oil leaks and maintains the integrity of the lubrication system.

Benefits

Using the Cummins 3421923 offers several benefits. It improves the efficiency of oil changes by providing a secure and easy-to-use connection point. The enhanced sealing properties reduce the risk of oil leaks, which can lead to engine damage and environmental contamination. Furthermore, by facilitating regular and efficient oil changes, this component contributes to the overall longevity of the engine.

Installation Process

Installing the Cummins 3421923 requires following a series of steps to ensure proper fitting and function. Begin by ensuring the engine is cool and the oil has been allowed to settle. Remove the old connection if replacing, and clean the area around the oil pan. Apply a thin layer of sealant to the threads of the new connection, then screw it into place by hand to avoid cross-threading. Tighten securely using the appropriate tool, following the manufacturer’s torque specifications.

Troubleshooting and Maintenance

Common issues with oil drain connections include leaks and difficulty in removal. To troubleshoot, check for proper installation and ensure the connection is tightened to the correct specifications. Regular maintenance involves inspecting the connection for signs of wear or corrosion and replacing it if necessary. Signs that indicate the need for replacement include persistent leaks, difficulty in opening or closing the connection, and visible damage to the component.

Safety Considerations

When working with oil drain connections, it is important to follow safety practices to protect yourself and the environment. Handle used oil carefully, using appropriate containers and disposal methods to prevent contamination. Ensure the connection is properly sealed to avoid leaks, which can pose a slip hazard and environmental risk. Always wear protective gear, such as gloves and safety glasses, when performing maintenance tasks.

Environmental Impact

Efficient oil drain connections play a role in minimizing the environmental impact of oil changes. By reducing the risk of spills and leaks, these components help prevent oil from contaminating soil and water sources. Additionally, proper disposal of used oil contributes to environmental conservation efforts, highlighting the importance of using reliable oil drain connections in maintenance routines 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation in diesel technology, Cummins is committed to advancing the industry through research and development. The company’s role in the automotive industry is marked by a dedication to quality, efficiency, and sustainability in engine technology.

Compatibility of Cummins Oil Drain Connection Part 3421923

The Cummins Oil Drain Connection part number 3421923 is designed to fit seamlessly with several engine models, ensuring efficient oil drainage and maintenance. This part is crucial for the proper functioning of the engines, facilitating the removal of used oil and preventing contamination.

QSV81G and QSW73 Engines

The part 3421923 is compatible with the QSV81G and QSW73 engines. These engines, while differing in some specifications, share common design elements that allow the oil drain connection to fit effectively. The design ensures that the oil drain process is smooth and reliable, contributing to the overall maintenance and longevity of the engines.

Grouping of Compatible Engines

In addition to the QSV81G and QSW73, the part 3421923 is also suitable for other engines within the same series or those with similar oil drainage systems. This compatibility extends to engines that share design features or have been manufactured with similar maintenance requirements. By ensuring that the oil drain connection fits these engines, Cummins maintains a high standard of quality and reliability across its engine lineup.

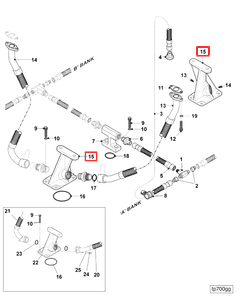

Role of Part 3421923 Oil Drain Connection in Engine Systems

The Part 3421923 Oil Drain Connection is integral to the efficient operation and maintenance of various engine systems, particularly those involving the turbocharger and its associated components.

Turbocharger Lubricating Oil Assembly

In the turbocharger lubricating oil assembly, the oil drain connection facilitates the removal of used oil, which is essential for maintaining the cleanliness and efficiency of the lubrication system. Regular draining helps prevent the buildup of contaminants that can degrade oil performance and lead to increased wear on turbocharger bearings and other moving parts.

Turbocharger Plumbing

Within the turbocharger plumbing system, the oil drain connection ensures that the oil circuits are free from old or contaminated oil. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. Efficient oil drainage helps maintain optimal oil pressure and temperature, which are vital for the reliable operation of the turbocharger.

General Plumbing

In the broader context of engine plumbing, the oil drain connection plays a role in the overall maintenance routine. It allows for the systematic removal of oil from various circuits, ensuring that all components reliant on lubrication receive fresh, clean oil. This practice is fundamental in preventing system-wide issues that could arise from neglected oil changes.

Turbocharger

For the turbocharger itself, the oil drain connection is a key component in the maintenance regimen. Turbochargers rely on precise lubrication to function correctly, and the ability to drain old oil ensures that the turbocharger can operate within its designed parameters, enhancing both performance and longevity.

Conclusion

The Part 3421923 Oil Drain Connection is a fundamental element in the maintenance and operational efficiency of turbocharger lubricating oil assemblies, turbocharger plumbing, general engine plumbing, and the turbocharger. Its role in facilitating the removal of used oil is essential for the sustained performance and reliability of these engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.