This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3235118 Lubricating Oil Pump is a critical component designed to facilitate the circulation of lubricating oil within heavy-duty truck engines. Its purpose is to ensure that engine parts receive adequate lubrication, which is essential for the smooth operation and longevity of the engine. This pump plays a significant role in maintaining the efficiency and reliability of heavy-duty trucks by supporting the lubrication system.

Basic Concepts of Lubricating Oil Pumps

Lubricating oil pumps operate on the principle of transferring oil from the oil pan to various engine components under pressure. The primary function of these pumps within an engine is to reduce friction between moving parts, dissipate heat, and remove contaminants. Effective lubrication is crucial for engine performance and longevity, as it minimizes wear and tear on engine components, ensuring they operate efficiently over extended periods 1.

Operation of the Cummins 3235118 Lubricating Oil Pump

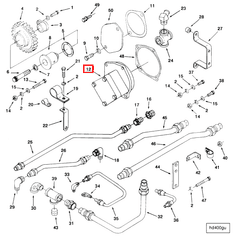

The Cummins 3235118 Lubricating Oil Pump operates through a gear-driven mechanism. It consists of a housing, gears, and a relief valve. As the engine runs, the gears rotate, drawing oil from the oil pan and pressurizing it before distributing it throughout the engine. This pump ensures that critical engine components, such as bearings, pistons, and camshafts, receive a continuous supply of lubricating oil, which is essential for their proper function and durability 2.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Cummins 3235118 Lubricating Oil Pump serves to enhance engine efficiency by ensuring that all moving parts are adequately lubricated. This reduces friction and wear, leading to smoother operation and potentially extending the engine’s lifespan. By maintaining optimal lubrication, the pump contributes to the overall performance and reliability of the truck, allowing it to operate under demanding conditions with reduced risk of mechanical failure 3.

Key Features

The Cummins 3235118 Lubricating Oil Pump is characterized by its robust design and the use of high-quality materials, which contribute to its durability and reliability. It is engineered to withstand the high pressures and temperatures typical of heavy-duty truck engines. Unique features may include advanced sealing technologies to prevent oil leaks and a precision-machined gear set to ensure efficient oil flow.

Benefits

Utilizing the Cummins 3235118 Lubricating Oil Pump offers several advantages, including improved engine reliability due to consistent lubrication. This can lead to extended maintenance intervals, as well-lubricated engines are less prone to wear and damage. Additionally, by enhancing engine performance and longevity, this pump can contribute to potential cost savings for fleet operators through reduced maintenance and repair expenses.

Troubleshooting and Maintenance

Common issues with the Cummins 3235118 Lubricating Oil Pump may include oil leaks, insufficient oil pressure, or pump failure. Troubleshooting these problems often involves checking for worn seals, clogged oil passages, or damaged gears. Regular maintenance practices, such as inspecting for leaks, monitoring oil pressure, and following the manufacturer’s recommended service intervals, are crucial for ensuring the pump’s optimal performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to manufacturing high-quality engine components that meet the demanding requirements of heavy-duty applications. The company’s dedication to innovation, quality, and customer satisfaction has established it as a trusted name in the production of engine parts, including the Cummins 3235118 Lubricating Oil Pump.

Cummins Lubricating Oil Pump Part 3235118 Compatibility

The Cummins lubricating oil pump part number 3235118 is designed to ensure efficient oil circulation within various engine systems. This part is engineered to meet the specific requirements of certain Cummins engines, ensuring optimal performance and longevity.

K19 Engine Group

The Cummins lubricating oil pump part 3235118 is compatible with the K19 engine series. This engine group is known for its robust design and reliability, often used in heavy-duty applications. The oil pump ensures that the engine’s moving parts receive adequate lubrication, reducing wear and tear and enhancing overall engine efficiency.

Other Compatible Engines

While the K19 series is a primary focus, the part 3235118 is also compatible with other Cummins engines within the same engine family. These engines share similar design characteristics and lubrication needs, making the oil pump a versatile component across multiple models.

The compatibility of the lubricating oil pump part 3235118 with these engines underscores its importance in maintaining engine health and performance. Proper installation and maintenance of this component are crucial for ensuring the longevity and efficiency of the engine systems it supports.

Role of Part 3235118 Lubricating Oil Pump in Engine Systems

The Part 3235118 Lubricating Oil Pump is integral to the efficient operation of engine systems by ensuring consistent oil circulation. This pump works in tandem with the lubricating oil scavenge pump to maintain optimal lubrication throughout the engine.

When the engine is running, the lubricating oil pump draws oil from the sump and pressurizes it before distributing it to various engine components. These components include the crankshaft, camshaft, pistons, and bearings. Proper lubrication reduces friction and wear, enhancing engine performance and longevity.

The scavenge pump plays a complementary role by returning used oil from the engine’s upper components back to the sump. This continuous cycle ensures that the oil remains clean and effective, preventing sludge buildup and maintaining viscosity.

In summary, the lubricating oil pump, along with the scavenge pump, forms a vital subsystem within the engine. It ensures that all moving parts receive a steady supply of lubricant, which is essential for smooth operation and durability.

Conclusion

The Cummins 3235118 Lubricating Oil Pump is a vital component in the maintenance and operation of heavy-duty truck engines. By ensuring consistent lubrication, this part plays a crucial role in reducing friction, enhancing engine performance, and extending the lifespan of engine components. Its robust design, compatibility with various Cummins engines, and the benefits it offers in terms of engine reliability and maintenance cost savings make it an essential component for fleet operators and engine manufacturers alike.

-

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.