This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

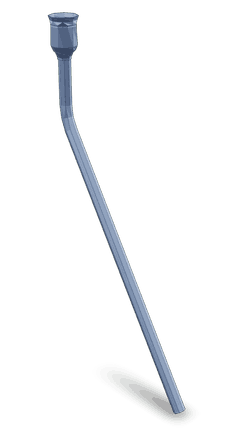

The Cummins 3233140 Oil Gauge Tube is a critical component in commercial trucks, facilitating the accurate measurement of oil levels within the engine. Proper oil level monitoring is essential for maintaining engine health and ensuring optimal performance.

Basic Concepts of Oil Gauge Tubes

An oil gauge tube allows for the measurement of oil levels within an engine by providing a pathway for oil to travel from the engine’s oil pan to the oil gauge on the dashboard. This setup enables drivers to monitor the oil level in real-time, ensuring that the engine is adequately lubricated. Accurate oil level monitoring is important for preventing engine damage due to insufficient lubrication 1.

Purpose of the Cummins 3233140 Oil Gauge Tube

This Cummins part ensures that the engine receives the correct amount of lubrication, which is important for maintaining engine performance and longevity. By providing accurate oil level readings, it helps in the timely identification of potential issues, such as oil leaks or consumption, allowing for proactive maintenance 2.

Key Features

The Cummins 3233140 Oil Gauge Tube is constructed from durable materials, ensuring longevity and reliability in demanding commercial truck environments. Its design includes features that enhance its functionality, such as a precise fitting to the oil gauge and resistance to corrosion and wear. These characteristics contribute to the overall effectiveness of the oil gauge tube in maintaining accurate oil level readings 3.

Benefits

Using the Cummins 3233140 Oil Gauge Tube offers several benefits. It contributes to improved engine performance by ensuring accurate oil levels, which is important for engine lubrication and cooling. The component’s durable construction and precise design enhance the reliability of oil level readings, facilitating easier maintenance and reducing the risk of engine damage due to incorrect oil levels.

Installation Process

Installing the Cummins 3233140 Oil Gauge Tube requires careful attention to detail. The process involves removing the old oil gauge tube, if present, and installing the new tube in its place. Tools required may include wrenches and possibly a socket set, depending on the specific truck model. Safety precautions, such as ensuring the engine is cool and disconnected from the power source, should be observed throughout the installation process.

Troubleshooting Common Issues

Common issues with the Cummins 3233140 Oil Gauge Tube may include inaccurate oil level readings or leaks around the tube. Troubleshooting steps may involve checking the tube for proper installation, ensuring there are no obstructions in the oil path, and inspecting for signs of wear or damage. Solutions may range from re-securing the tube to replacing it if damage is detected.

Maintenance Tips

Regular maintenance of the Cummins 3233140 Oil Gauge Tube is important for ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the tube and its surrounding area can prevent the buildup of debris that may affect its operation. Adhering to recommended inspection intervals and maintenance procedures will help maintain accurate oil level readings and engine performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and reliability in the commercial truck industry. Its product range includes a variety of components and systems designed to enhance the performance and efficiency of commercial vehicles.

Cummins Oil Gauge Tube (Part 3233140) Compatibility

The Cummins Oil Gauge Tube, identified by part number 3233140, is engineered to ensure accurate oil pressure readings, which are essential for maintaining engine health and performance. This part is compatible with various Cummins engines, including the K19 engine series, ensuring precise oil pressure measurements and contributing to the overall efficiency and longevity of the engine.

Role of Part 3233140 Oil Gauge Tube in Engine Systems

This part is an integral component in the monitoring and maintenance of engine systems, specifically in relation to the gauge and oil level. The tube facilitates the accurate measurement and display of the oil level within the engine, ensuring that the lubrication system operates within optimal parameters.

Integration with the Gauge

The Oil Gauge Tube is directly connected to the gauge, which is responsible for providing a visual indication of the oil level to the operator. The tube acts as a conduit, transferring the oil level data from the engine’s sump to the gauge. This allows for real-time monitoring, enabling the operator to make informed decisions regarding oil changes or potential issues within the lubrication system.

Interaction with Oil Level

Maintaining the correct oil level is essential for the efficient operation and longevity of an engine. The Oil Gauge Tube plays a significant role in this process by ensuring that the oil level sensor receives accurate information about the amount of oil present in the sump. This data is then transmitted to the gauge, allowing for precise monitoring and maintenance of the oil level.

Conclusion

The Cummins 3233140 Oil Gauge Tube is a key component in the engine’s lubrication system, working in tandem with the gauge and oil level to ensure the engine operates smoothly and efficiently. Its durable construction, precise design, and compatibility with various Cummins engines make it an essential part for maintaining engine health and performance.

-

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Dixon, J. (2014). Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning.

↩ -

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.