This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

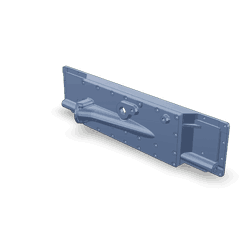

The Cummins 3201157 Oil Cooler is a specialized component designed for heavy-duty truck applications. Its purpose is to regulate the temperature of engine oil, ensuring it remains within optimal operating ranges. This regulation is significant for maintaining engine efficiency, performance, and longevity in demanding operational environments 3.

Basic Concepts of Oil Coolers

An oil cooler is a heat exchanger that removes excess heat from engine oil. It operates by circulating oil through a series of tubes or fins, where heat is transferred to a cooler medium, typically the ambient air. This process is vital for dissipating the heat generated during engine operation, which if not managed, can lead to oil degradation and engine damage 2.

Purpose of the Cummins 3201157 Oil Cooler

The Cummins 3201157 Oil Cooler plays a role in maintaining optimal engine oil temperature by facilitating efficient heat exchange. This regulation ensures that the oil retains its viscosity and lubricating properties, which are crucial for reducing friction and wear on engine components. By keeping the oil at the correct temperature, the cooler contributes to efficient engine performance and extends engine life 3.

Key Features

This Cummins part is characterized by its robust design, which includes high-quality materials that enhance durability and performance. It features a compact yet efficient structure that maximizes heat exchange capabilities. The cooler is engineered to withstand the harsh conditions typical of heavy-duty truck operations, ensuring reliable performance over extended periods 1.

Benefits of Using the Cummins 3201157 Oil Cooler

Utilizing the Cummins 3201157 Oil Cooler offers several advantages. It improves engine efficiency by ensuring that the oil remains at an optimal temperature, which reduces the risk of overheating and associated engine damage. Additionally, it enhances overall engine reliability, contributing to smoother operation and potentially reducing maintenance costs 3.

Installation and Integration

Proper installation of the Cummins 3201157 Oil Cooler involves integrating it into the truck’s engine system with attention to detail. This process may require specific preparations, such as ensuring compatibility with the engine model and making necessary adjustments to the existing cooling system. Careful installation is key to maximizing the cooler’s effectiveness and ensuring it operates as intended 1.

Maintenance and Troubleshooting

Routine maintenance practices for the Cummins 3201157 Oil Cooler include regular inspections for signs of wear or damage, ensuring all connections are secure, and checking for any leaks. Troubleshooting common issues may involve addressing blockages within the cooler, ensuring proper airflow, and verifying that the cooler is functioning within the expected temperature range 3.

Performance and Efficiency

The Cummins 3201157 Oil Cooler contributes to overall engine performance and fuel efficiency in heavy-duty trucks by maintaining optimal oil temperature. This regulation allows the engine to operate more efficiently, potentially leading to improved fuel economy and reduced emissions. The cooler’s efficient design and robust construction play a significant role in achieving these performance benefits 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and a strong reputation in the automotive industry, Cummins is committed to producing high-quality engine components. The company’s dedication to excellence is reflected in its products, including the Cummins 3201157 Oil Cooler, which is designed to meet the demanding requirements of heavy-duty truck applications 1.

Compatibility

The Cummins Oil Cooler part number 3201157 is designed to be compatible with a variety of engine models, ensuring efficient oil cooling and maintaining optimal engine performance. This oil cooler is engineered to fit seamlessly with the following engines:

- K19

For the K19 engine, the oil cooler 3201157 plays a role in managing the temperature of the engine oil. Proper installation and maintenance of this component are essential for preventing overheating and ensuring the longevity of the engine. The design of the oil cooler allows it to integrate smoothly with the engine’s architecture, providing effective heat dissipation and contributing to the overall reliability of the engine 1.

Role of Part 3201157 Oil Cooler in Engine Systems

This part is an essential component in maintaining the optimal performance and longevity of various engine systems. It is specifically designed to regulate the temperature of the oil circulating within these systems, ensuring that it remains within a safe operating range.

Integration with Torque Converter Oil Systems

In automatic transmission systems, the torque converter relies on a consistent supply of cool oil to function efficiently. The oil cooler, part 3201157, is integrated into the torque converter oil circuit to dissipate excess heat generated during operation. This cooling process prevents thermal degradation of the oil, which can lead to decreased transmission performance and potential failure. The cooler works in tandem with the transmission’s oil pump, ensuring that the oil delivered to the torque converter maintains the necessary viscosity and lubricating properties 2.

Function within General Oil Cooling Systems

Beyond the torque converter, the oil cooler plays a significant role in broader oil cooling applications within engine systems. It is often connected to the engine’s lubrication circuit, where it cools the oil after it has absorbed heat from various engine components, such as the crankshaft, camshaft, and valve train. By reducing the temperature of the oil before it is recirculated, the cooler helps to maintain the oil’s integrity, ensuring it continues to provide effective lubrication and protection against wear 2.

Enhanced Performance and Reliability

The incorporation of part 3201157 Oil Cooler into these systems not only enhances the performance of the engine and transmission but also contributes to their reliability. Consistent oil temperature regulation helps to prevent issues such as oil breakdown, sludge formation, and component wear, which can lead to costly repairs and downtime 3.

Conclusion

In summary, the oil cooler is a vital component in the thermal management of engine and transmission systems, playing a key role in preserving the efficiency and durability of these critical engine components.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ ↩ ↩ ↩ -

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ ↩ ↩ -

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.