The Oil Level Gauge Tube, part number 3035659, manufactured by Cummins, is a component designed to monitor oil levels within the engine system of heavy-duty trucks. Its role is significant in ensuring the engine operates efficiently and remains well-lubricated. Cummins, a well-established name in the automotive industry, is known for producing reliable and high-quality parts for heavy-duty applications 1.

Function and Operation

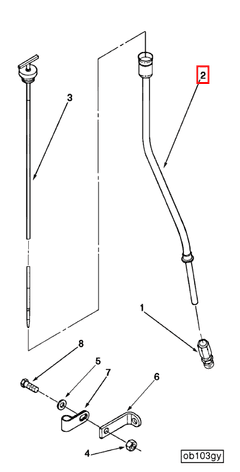

The Oil Level Gauge Tube operates by providing a pathway for the oil level sensor to accurately measure the amount of oil within the engine. This measurement is crucial for maintaining proper lubrication, which is vital for the engine’s performance and longevity. The gauge tube is connected to the oil pan and extends to the sensor, allowing for continuous monitoring of oil levels 2.

Key Features

This Cummins part is constructed from durable materials, ensuring it can withstand the harsh conditions within a heavy-duty truck engine. Its design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube is engineered to be compatible with Cummins engines, ensuring optimal performance and integration within the engine system 3.

Benefits

One of the primary advantages of the Oil Level Gauge Tube 3035659 is its ability to provide accurate oil level readings, which is fundamental for maintaining engine health. Its durable construction ensures longevity, reducing the need for frequent replacements. Furthermore, the design of the tube facilitates ease of installation, minimizing downtime during maintenance procedures.

Installation Process

Installing the Oil Level Gauge Tube involves several steps to ensure proper integration within the engine system. First, the engine oil should be drained to facilitate easier access to the oil pan. Next, the old gauge tube, if present, should be removed. The new tube is then inserted into the oil pan and connected to the oil level sensor. It is important to use the appropriate tools and follow manufacturer guidelines to ensure a secure and leak-free installation.

Maintenance Tips

Regular maintenance of the Oil Level Gauge Tube is important for ensuring its effectiveness and longevity. This includes periodic inspection for signs of wear or damage, cleaning the tube and sensor to remove any debris, and ensuring all connections are secure. If the tube shows signs of significant wear or if accurate oil level readings are compromised, replacement may be necessary.

Troubleshooting Common Issues

Common issues with the Oil Level Gauge Tube may include inaccurate oil level readings or leaks at the connection points. Inaccurate readings can often be resolved by cleaning the sensor and ensuring the tube is properly installed. Leaks may require tightening connections or, in some cases, replacing the tube if damage is detected.

Safety Considerations

When working with the Oil Level Gauge Tube, it is important to follow safety practices to prevent injury and ensure accurate installation. This includes wearing appropriate personal protective equipment, ensuring the engine is cool before beginning work, and following all manufacturer guidelines for installation and maintenance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, particularly in the heavy-duty truck sector, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and related components, all designed to meet the demanding requirements of heavy-duty applications.

Cummins Oil Level Gauge Tube (Part 3035659) Compatibility

The Cummins Oil Level Gauge Tube, part number 3035659, is a critical component in the engine’s oil management system. This part is designed to fit seamlessly with several Cummins engine models, ensuring accurate oil level monitoring and maintaining engine health.

N14 CELECT and N14 CELECT PLUS Engines

The Oil Level Gauge Tube is compatible with the N14 CELECT and N14 CELECT PLUS engines. These engines are known for their robust design and advanced electronic controls, making them suitable for heavy-duty applications. The part ensures that the oil level can be accurately monitored, which is essential for preventing engine damage due to low oil levels.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Oil Level Gauge Tube is also a perfect fit. This engine variant relies on mechanical controls rather than electronic systems, but it still benefits from the precise oil level monitoring provided by this part. The compatibility ensures that operators can maintain optimal oil levels, contributing to the engine’s longevity and performance.

NH/NT 855 Engines

The Oil Level Gauge Tube is also designed to fit the NH/NT 855 engines. These engines are part of the Cummins lineup that offers a balance of power and efficiency, making them ideal for various applications. The part’s compatibility with these engines ensures that the oil level can be monitored accurately, which is crucial for maintaining engine efficiency and preventing potential issues.

By ensuring compatibility with these engines, the Cummins Oil Level Gauge Tube (part 3035659) provides a reliable solution for oil level monitoring across different engine models. This compatibility highlights the versatility and importance of the part in maintaining engine health and performance.

Role of Part 3035659 Oil Level Gauge Tube in Engine Systems

The Part 3035659 Oil Level Gauge Tube is an essential component in the oil management system of an engine, working in conjunction with several other components to ensure the engine operates efficiently and safely.

Integration with Dipstick Arrangement

The Oil Level Gauge Tube interfaces directly with the dipstick arrangement. This arrangement typically consists of a dipstick tube and the dipstick itself, which is used to manually check the oil level. The gauge tube provides a pathway for the dipstick to be inserted into the engine’s oil sump. Accurate measurement is vital for maintaining proper oil levels, which in turn ensures adequate lubrication of engine components, preventing wear and potential damage.

Function within Oil Fill Arrangement

In the oil fill arrangement, the Oil Level Gauge Tube plays a supportive role. This arrangement includes the oil filler cap, the oil filler neck, and associated gaskets and seals. The gauge tube is positioned to allow for the easy addition of oil when top-ups are necessary. It ensures that oil is directed correctly into the sump, minimizing the risk of spills and ensuring that the oil reaches its intended destination within the engine.

Interaction with Oil Gauge Tube

Naturally, the Oil Level Gauge Tube is integral to the oil gauge system itself. This system often includes an electronic sensor or a mechanical float that detects the oil level within the sump. The gauge tube houses this sensor or float, transmitting the oil level data to the engine’s control unit or directly to the dashboard gauge. This real-time feedback allows for continuous monitoring of oil levels, enabling prompt action if levels fall below the safe operating range.

Conclusion

In summary, the Part 3035659 Oil Level Gauge Tube is a key component that ensures the accurate measurement and maintenance of oil levels within an engine. Its interaction with the dipstick arrangement, oil fill arrangement, and the oil gauge system underscores its importance in the overall health and performance of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.