This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3010616 Oil Cooler is a component designed to regulate the temperature of engine oil in commercial trucks. Its role is significant in maintaining the efficiency and longevity of the engine. By ensuring that the oil remains within optimal temperature ranges, the oil cooler contributes to the stable operation of the engine under various driving conditions.

Basic Concepts of Oil Coolers

An oil cooler is a device that helps maintain the temperature of engine oil within specified limits. It functions by transferring excess heat from the oil to the surrounding air or coolant, thus preventing overheating. The principle of heat exchange is fundamental to its operation, where heat is dissipated from the hotter fluid (engine oil) to a cooler medium (air or coolant). Regulating oil temperature is vital for heavy-duty engines, as it ensures that the oil retains its viscosity and lubricating properties, which are essential for engine components’ protection and performance 1.

Purpose of the Cummins 3010616 Oil Cooler

The Cummins 3010616 Oil Cooler is specifically engineered to play a role in the engine’s cooling system by managing the temperature of the engine oil. This management contributes to engine efficiency by ensuring that the oil does not become too viscous in cold conditions or too thin in hot conditions. Maintaining optimal oil temperature aids in prolonging engine life by reducing wear on moving parts and enhancing overall performance by ensuring that the engine operates within its designed parameters 2.

Key Features

The Cummins 3010616 Oil Cooler is characterized by several design elements and materials that enhance its functionality and durability. It is constructed using high-quality materials resistant to corrosion and high temperatures, ensuring longevity and reliable performance. The design incorporates efficient heat exchange mechanisms, allowing for effective cooling even under demanding conditions. Unique characteristics may include a compact design for space efficiency and robust construction to withstand the rigors of heavy-duty truck operation.

Benefits of Using the Cummins 3010616 Oil Cooler

Incorporating the Cummins 3010616 Oil Cooler into a truck’s engine system offers several advantages. It contributes to improved engine performance by ensuring that the oil maintains its optimal viscosity, thus enhancing lubrication and reducing friction. Extended engine life is another benefit, as consistent oil temperature helps prevent premature wear and damage to engine components. Additionally, the efficient operation of the oil cooler can lead to enhanced fuel efficiency, as the engine operates more smoothly and with less resistance 3.

Installation and Integration

When installing the Cummins 3010616 Oil Cooler, it is important to consider compatibility with the truck’s engine model and integration with the existing cooling system. Proper installation ensures that the oil cooler functions effectively within the engine’s cooling circuit, contributing to the overall efficiency of the cooling system. Guidelines for installation may include ensuring proper alignment, secure mounting, and correct connection to the oil lines.

Maintenance and Troubleshooting

Regular maintenance practices are recommended to ensure the optimal performance of the Cummins 3010616 Oil Cooler. This may include periodic inspection for signs of wear, corrosion, or leaks, and ensuring that the cooling fins are free from debris that could impede heat exchange. Troubleshooting common issues may involve checking for proper oil flow, ensuring that the cooler is securely mounted, and verifying that there are no obstructions in the cooling pathways. Identifying and addressing potential problems promptly can help maintain the efficiency and reliability of the oil cooler.

Performance and Efficiency

The Cummins 3010616 Oil Cooler contributes to the overall performance and efficiency of a truck’s engine by ensuring that the engine oil remains at an optimal temperature. This temperature regulation plays a role in reducing fuel consumption, as the engine operates more efficiently with properly lubricated components. It also contributes to lower emissions, as the engine’s combustion process is more consistent and complete when the oil is at the correct temperature. Furthermore, the reliability of the engine is enhanced, as consistent oil temperature helps prevent unexpected failures and extends the engine’s operational life.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive and heavy-duty truck industry, known for its commitment to innovation, quality, and customer satisfaction. With a history of developing reliable and high-performance engine components, Cummins has built a reputation for excellence in the field. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Compatibility with V28 Engines

The Cummins Oil Cooler part number 3010616 is specifically designed to fit seamlessly within the V28 engine series. This part is integral to maintaining optimal engine performance by efficiently cooling the engine oil, which is crucial for the longevity and efficiency of the engine.

V28 Engine Series

The V28 engine series, known for its robust design and high performance, benefits significantly from the precise engineering of the Cummins Oil Cooler 3010616. This oil cooler is engineered to fit snugly within the engine’s architecture, ensuring that it can effectively dissipate heat from the oil, thereby preventing overheating and maintaining the viscosity of the oil at optimal levels.

The compatibility of the Cummins Oil Cooler 3010616 with the V28 engines is a result of meticulous design and testing. Cummins has ensured that this oil cooler is not only a perfect fit but also enhances the overall efficiency and reliability of the V28 engines. The design takes into account the specific thermal and spatial requirements of the V28 engines, making it an ideal choice for these models.

Grouping of V28 Engines

When considering the V28 engine series, it is important to note that the Cummins Oil Cooler 3010616 is compatible across various iterations and configurations within this series. This includes engines used in heavy-duty applications, where consistent and reliable cooling is paramount. The design of the oil cooler ensures that it can handle the high thermal loads and demanding operational conditions typical of these engines.

By integrating the Cummins Oil Cooler 3010616 into the V28 engine series, users can expect enhanced engine performance, reduced maintenance needs, and improved overall reliability. This compatibility is a testament to Cummins’ commitment to providing high-quality, durable, and efficient engine components.

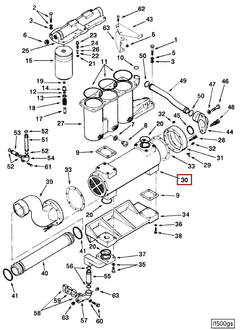

Role of Part 3010616 Oil Cooler in Engine Systems

The part 3010616 Oil Cooler is an integral component in maintaining the optimal performance and longevity of engine systems. It works in conjunction with several other components to ensure the engine operates efficiently under various conditions.

Interaction with Lubricating Oil Components

-

Lubricating Oil: The primary function of the oil cooler is to regulate the temperature of the lubricating oil. As the engine operates, the lubricating oil absorbs heat. The oil cooler dissipates this heat, preventing the oil from becoming too hot, which can lead to breakdown and reduced effectiveness.

-

Lubricating Oil Filter: After passing through the oil cooler, the regulated lubricating oil moves to the lubricating oil filter. Here, any contaminants that may have been picked up by the oil are removed, ensuring that only clean oil circulates through the engine. This synergy between the oil cooler and the filter helps maintain the integrity of the lubricating oil.

-

Lubricating Oil Filter Assembly: The assembly includes various components that work together to filter the oil. The cooled oil, having been through the oil cooler, enhances the efficiency of the filter assembly by ensuring that the oil is at an optimal temperature for filtration. This results in better removal of impurities and prolonged filter life.

Integration with Oil Filter and Cooler Systems

-

Oil Filter / Cooler: In systems where the oil filter and cooler are combined, the 3010616 Oil Cooler plays a dual role. It not only cools the oil but also ensures that the oil entering the filter is at an ideal temperature. This integration improves the overall efficiency of the oil management system within the engine.

-

Cooler Lubricating Filter: In some advanced engine systems, a cooler lubricating filter is used. The oil cooler ensures that the oil is cooled before it reaches this filter, enhancing its performance. The cooler lubricating filter can then more effectively remove contaminants from the oil, leading to better engine protection and performance.

By effectively managing the temperature of the lubricating oil, the 3010616 Oil Cooler ensures that all associated components function at their best, contributing to the overall reliability and efficiency of the engine system.

Conclusion

The Cummins 3010616 Oil Cooler is a critical component in the maintenance of engine efficiency and longevity in commercial trucks. Its role in regulating engine oil temperature ensures optimal engine performance, reduced wear, and enhanced fuel efficiency. Proper installation, regular maintenance, and understanding its integration with other engine components are essential for maximizing the benefits of this Cummins part. The compatibility of the 3010616 with the V28 engine series further underscores its importance in heavy-duty applications, where reliable cooling is essential.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.