This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

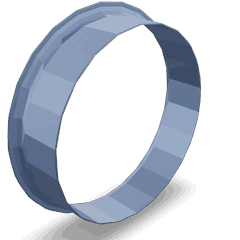

The Cummins 3010464 Wear Sleeve is a component designed for use in commercial trucks, specifically within the engine system. Its primary role is to enhance the durability and efficiency of the engine by providing a protective barrier between moving parts. This Cummins part is integral to maintaining the optimal performance of the truck’s engine, ensuring smooth operation and longevity of the engine components 1.

Purpose and Function

The Cummins 3010464 Wear Sleeve serves to reduce friction and wear on moving parts within the truck’s engine system. By creating a low-friction surface, it minimizes the direct contact between metal components, which can lead to wear and tear over time. This reduction in friction not only enhances the efficiency of the engine but also contributes to the overall reliability and performance of the truck. The wear sleeve operates by fitting snugly around specific engine components, providing a cushion that absorbs impact and reduces the stress on these parts 2.

Key Features

The Cummins 3010464 Wear Sleeve is characterized by its robust material composition, typically made from high-quality alloys or composite materials that offer superior resistance to wear and corrosion. Its design is tailored to fit precisely within the engine, ensuring a secure and effective installation. Unique characteristics of this wear sleeve include its smooth surface finish, which further reduces friction, and its ability to withstand high temperatures and pressures common in commercial truck engines 3.

Benefits

Incorporating the Cummins 3010464 Wear Sleeve into a truck’s engine system offers several benefits. It contributes to improved engine efficiency by reducing friction, which can lead to better fuel economy. Additionally, by protecting engine components from excessive wear, it extends the lifespan of these parts, reducing the frequency of replacements and repairs. This, in turn, lowers maintenance requirements and costs, making it a valuable component for fleet operators looking to maximize uptime and minimize expenses 4.

Installation and Usage

Proper installation of the Cummins 3010464 Wear Sleeve is crucial for ensuring its effectiveness and longevity. It should be installed according to the manufacturer’s guidelines, which typically involve cleaning the mating surfaces, applying the correct lubricant, and ensuring a snug fit without over-tightening. Regular inspections during routine maintenance checks can help identify any signs of wear or damage early, allowing for timely replacement and continued optimal performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3010464 Wear Sleeve may include signs of wear, such as grooves or uneven surfaces, which can indicate excessive friction or misalignment. Regular maintenance practices, such as cleaning and inspecting the wear sleeve during oil changes or engine overhauls, can help prolong its service life. If wear is detected, it is advisable to replace the sleeve to prevent further damage to the engine components. Additionally, ensuring that the engine operates within recommended parameters can help maintain the integrity of the wear sleeve and other engine parts.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry for quality and innovation, Cummins has been committed to providing reliable and efficient solutions for commercial vehicles for over a century. Their components, including the Cummins 3010464 Wear Sleeve, are designed with precision and durability in mind, reflecting the company’s dedication to excellence in automotive and heavy-duty truck parts.

Conclusion

The Cummins 3010464 Wear Sleeve plays a significant role in enhancing the durability and efficiency of commercial truck engines. By reducing friction and wear on engine components, it contributes to improved engine performance, fuel efficiency, and longevity. Proper installation, regular maintenance, and timely replacement are essential for maximizing the benefits of this Cummins part. Cummins Inc.’s commitment to quality and innovation is evident in the design and functionality of the 3010464 Wear Sleeve, making it a valuable component for fleet operators.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

Hilgers, Michael. Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature, 2023.

↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.