This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

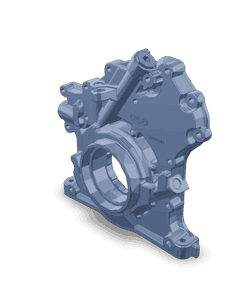

The Cummins 2830913 Lubricating Oil Pump is a component designed to facilitate the circulation of oil within the engine of commercial trucks. Its role is significant in maintaining the operational efficiency and longevity of the engine by ensuring that all moving parts receive adequate lubrication 1.

Basic Concepts of Lubricating Oil Pumps

A lubricating oil pump is a device that circulates oil throughout an engine to reduce friction between moving parts, remove heat, and carry away contaminants. Proper lubrication is vital for the smooth operation of engine components, as it minimizes wear and tear, enhances performance, and contributes to the overall reliability of the engine 2.

Purpose of the Cummins 2830913 Lubricating Oil Pump

This Cummins part is integral to the operation of a truck’s engine. It functions by drawing oil from the sump and distributing it to various engine parts, including the crankshaft, camshaft, and valve train. This circulation of oil plays a role in reducing friction, dissipating heat, and cleaning the engine by carrying away debris 3.

Key Features

The 2830913 is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and efficiency. The pump’s design ensures consistent oil flow, while the materials used are selected for their ability to withstand the harsh conditions within an engine environment.

Benefits of Using the Cummins 2830913 Lubricating Oil Pump

Utilizing this part can lead to enhanced engine performance, increased longevity, and improved reliability. The pump’s efficient oil circulation contributes to reduced engine wear, lower operating temperatures, and a cleaner engine environment, all of which are beneficial for the overall health and performance of the engine.

Installation and Integration

Proper installation of the 2830913 within a truck’s engine system is crucial for its effective operation. This process involves ensuring that the pump is correctly aligned and securely fastened, and that all connections are properly sealed. It is also important to verify that the pump is compatible with the engine’s specifications and that all prerequisites for installation are met.

Maintenance Practices

To ensure the optimal performance and longevity of the 2830913, regular maintenance practices are recommended. These include periodic inspections for signs of wear or damage, ensuring that oil levels are adequate, and servicing the pump as necessary to maintain its efficiency and reliability.

Troubleshooting Common Issues

Common issues that may arise with the 2830913 include inadequate oil pressure, leaks, or pump failure. Troubleshooting these issues involves checking for blockages in the oil passages, inspecting seals and gaskets for wear, and assessing the pump’s mechanical condition. Addressing these problems promptly can help maintain the pump’s performance and prevent more serious engine issues.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and efficient components for the automotive and heavy-duty truck industries. The company’s dedication to excellence is reflected in its products, including the 2830913 Lubricating Oil Pump.

Role of Part 2830913 Lubricating Oil Pump in Engine Systems

The 2830913 lubricating oil pump is an integral component in the engine’s lubrication system, ensuring that all moving parts receive adequate lubrication for optimal performance and longevity.

Integration with Engine Components

-

Crankshaft and Connecting Rods: The lubricating oil pump delivers oil to the crankshaft and connecting rods, reducing friction and wear. This is essential for maintaining the smooth operation of these components, which are subject to high loads and rotational speeds.

-

Camshaft and Valve Train: Proper lubrication is vital for the camshaft and valve train. The pump ensures a consistent oil supply, which minimizes wear on the cam lobes, lifters, and rocker arms, thereby enhancing the engine’s efficiency and reliability.

-

Pistons and Cylinder Walls: The pump facilitates the distribution of oil to the pistons and cylinder walls. This lubrication reduces friction and heat, preventing seizing and ensuring a tight seal between the piston rings and cylinder walls.

-

Bearings: All engine bearings, including main and rod bearings, depend on a steady oil flow provided by the pump. This lubrication is necessary to reduce metal-to-metal contact, which can lead to premature bearing failure.

-

Timing Chain or Belt: For engines equipped with a timing chain or belt, the lubricating oil pump plays a role in maintaining proper lubrication. This ensures smooth operation and reduces the risk of timing issues, which can lead to severe engine damage.

-

Oil Filter: The pump works in conjunction with the oil filter to circulate clean oil throughout the engine. This collaboration is essential for removing contaminants and maintaining oil quality, which is crucial for the engine’s overall health.

-

Oil Cooler: In engines with an oil cooler, the pump ensures that oil is circulated through the cooler, maintaining optimal oil temperature. This is particularly important in high-performance or high-stress applications where oil temperature can significantly affect engine performance.

-

Turbocharger (if equipped): For turbocharged engines, the lubricating oil pump also supplies oil to the turbocharger bearings and seals. This lubrication is necessary to handle the high speeds and loads associated with turbocharger operation.

Conclusion

In summary, the 2830913 lubricating oil pump is a fundamental component that ensures the engine’s moving parts are adequately lubricated, thereby enhancing performance, reliability, and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.