S212

Regular Hexagon Nut

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

Minimum Quantity 2

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The S212 Regular Hexagon Nut, a component manufactured by Cummins, is a critical part in the commercial truck industry. This nut is specifically designed for use in commercial trucks, where it plays a significant role in the assembly and maintenance of various truck components.

Basic Concepts of Regular Hexagon Nuts

A regular hexagon nut is a type of fastener characterized by its six-sided shape. This design allows for efficient torque application and resistance to loosening, making it a popular choice in various fastening applications. The hexagonal shape provides a larger contact area compared to other shapes, which enhances the grip and reduces the likelihood of the nut rounding off during tightening or loosening 1.

Role of the S212 Regular Hexagon Nut in Truck Operation

In the context of commercial trucks, the S212 Regular Hexagon Nut is utilized in the assembly and maintenance of critical components. It is often employed in conjunction with bolts to secure parts that are subject to significant stress and vibration, such as engine components, chassis parts, and suspension systems. The nut’s design ensures a secure fit that can withstand the rigors of heavy-duty truck operation 2.

Key Features

The S212 Regular Hexagon Nut is crafted from high-quality materials, typically featuring a robust thread type that ensures a strong and reliable connection. Depending on the application, it may also include special coatings or treatments to enhance corrosion resistance and durability. These features contribute to the nut’s ability to perform effectively in the demanding environment of commercial truck operations 3.

Benefits

Using the S212 Regular Hexagon Nut offers several advantages. Its durable construction and resistance to loosening make it a reliable choice for fastening applications. Additionally, the hexagonal shape allows for easy use with standard tools, facilitating efficient installation and removal. These qualities contribute to the overall reliability and maintainability of commercial trucks 4.

Troubleshooting and Maintenance

Regular maintenance and proper installation are key to ensuring the longevity and proper function of the S212 Regular Hexagon Nut. Common issues may include loosening due to vibration or corrosion. To address these, it is important to check for proper torque during installation and to inspect nuts regularly for signs of wear or corrosion. Applying the correct lubricants and using anti-seize compounds where appropriate can also help prevent issues 5.

Cummins Engine Compatibility with S212 Regular Hexagon Nut

The S212 Regular Hexagon Nut, manufactured by Cummins, is a versatile component that fits into a variety of Cummins engines. This part is designed to meet the stringent quality and performance standards set by Cummins, ensuring reliable and durable performance across different engine models.

G-Series Engines

The G-Series engines, including the G855, G855 CM558, GTA38 G CMEICS G116C, and GTA855 CM558 (CM2358) G101, are compatible with the S212 Regular Hexagon Nut. These engines are known for their robust construction and are often used in heavy-duty applications.

K-Series Engines

The K-Series engines, such as the K19, K38, K50, KTA19GC, KTA19GC CM558, and KTA38GC CM558, also utilize the S212 Regular Hexagon Nut. These engines are designed for high-performance and reliability, making them suitable for a wide range of industrial and commercial applications.

L-Series Engines

The L-Series engines, including the L10 CELECT, L10 GAS, and L10 MECHANICAL, are compatible with the S212 Regular Hexagon Nut. These engines are engineered for efficiency and durability, making them ideal for both on-road and off-road use.

M-Series Engines

The M-Series engine, specifically the M11 CELECT PLUS, is designed to work with the S212 Regular Hexagon Nut. This engine is known for its advanced technology and high performance, making it a popular choice in various applications.

N-Series Engines

The N-Series engines, such as the N14 CELECT, N14 G, and N14 MECHANICAL, are compatible with the S212 Regular Hexagon Nut. These engines are built for reliability and efficiency, making them suitable for heavy-duty operations.

NH/NT 855

The NH/NT 855 engine is also compatible with the S212 Regular Hexagon Nut. This engine is designed for high performance and durability, making it a reliable choice for demanding applications.

QSB5.9 CM850

The QSB5.9 CM850 engine is compatible with the S212 Regular Hexagon Nut. This engine is known for its power and efficiency, making it suitable for a variety of industrial and commercial uses.

QSK19 CM2350 Series

The QSK19 CM2350 engines, including the K105, K114, K144G, CM500, CM850 MCRS, and CM2150 MCRS, are all compatible with the S212 Regular Hexagon Nut. These engines are designed for high performance and reliability, making them ideal for a wide range of applications.

By ensuring compatibility with the S212 Regular Hexagon Nut, Cummins maintains a high standard of quality and performance across its diverse range of engines. This compatibility allows for easier maintenance and repair, enhancing the overall reliability and longevity of the engines.

Role of Part S212 Regular Hexagon Nut in Engine Systems

The S212 Regular Hexagon Nut is integral to the assembly and securement of various components within engine systems. Its application spans across multiple critical areas, ensuring the stability and functionality of the engine.

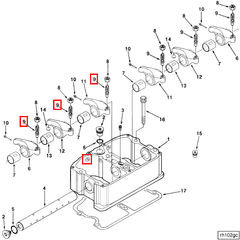

Cylinder Long Block Assembly

In the cylinder long block, the S212 nut is employed to fasten the cylinder head to the block. This securement is vital for maintaining the integrity of the combustion chamber and ensuring proper sealing. The nut’s hexagonal shape allows for efficient tightening using standard tools, which is essential during both initial assembly and maintenance procedures.

Engine Brake Control and Rocker Assemblies

The S212 nut plays a significant role in the engine brake control system, particularly in securing the EBM-lever and various rocker assemblies. These components are subject to significant stress and vibration, making the reliable fastening provided by the S212 nut essential for their operation. The nut ensures that the levers and rockers remain in their correct positions, contributing to the precise control of engine braking and valve operation.

Exhaust Manifold and Turbocharger Mounting

When it comes to the exhaust manifold and turbocharger mounting, the S212 nut is used to secure these components to the engine block. This is particularly important given the high temperatures and pressures involved in exhaust systems. The nut’s design helps in withstanding thermal expansion and contraction, maintaining a secure fit over the engine’s operational life.

Corrosion Resistor and Filter Brackets

In corrosion resistor and filter brackets, the S212 nut is utilized to attach these components to the engine frame or block. This application is key in environments where corrosion resistance is paramount, such as marine applications. The secure attachment provided by the nut ensures that these brackets remain firmly in place, protecting sensitive engine parts from corrosive elements.

Fan and Freon Compressor Mounting

For the fan bracket and freon compressor mounting, the S212 nut is critical in ensuring these components are securely attached to the engine. This is important for the efficient operation of cooling and air conditioning systems, which are essential for maintaining optimal engine temperature and comfort in vehicle cabins.

Idler Gear and Rear Gear Mounting Cover

In the idler gear and rear gear mounting cover, the S212 nut facilitates the secure attachment of these components, which are vital for the smooth operation of the engine’s timing and gear systems. Proper fastening is essential to prevent misalignment and ensure the efficient transfer of power within the engine.

Injector and Lever Assemblies

The S212 nut is also found in injector (top level assembly) lever and rocker injector lever applications. Here, it ensures that injectors and levers are securely mounted, allowing for precise fuel delivery and valve operation. This is fundamental for engine performance and efficiency.

Vibration Damper and Torque Converter

Lastly, in the vibration damper and torque converter, the S212 nut is used to secure these components, which are essential for smoothing out engine vibrations and efficiently transferring power from the engine to the transmission. The secure attachment provided by the nut is crucial for the durability and performance of these components.

Overall, the S212 Regular Hexagon Nut is a versatile and essential component in engine systems, contributing to the securement and stability of a wide range of engine parts.

Conclusion

The S212 Regular Hexagon Nut is a critical component in the commercial truck industry, providing reliable and durable fastening solutions for a variety of engine and truck components. Its compatibility with a wide range of Cummins engines, coupled with its robust design and ease of use, makes it an indispensable part in the maintenance and operation of commercial trucks.

-

Quansheng Zhan, Shengbo Eben, Li Kun Deng, Automotive Heating Ventilation and Air Conditioning, Jones Bartlett Learning, 2018.

↩ -

Jon M. Quigley, SAE International’s Dictionary of Testing, Verification and Validation, SAE International, 2023.

↩ -

Julian Happian-Smith, An Introduction to Modern Vehicle Design, Butterworth-Heinemann, 2002.

↩ -

A. J. Wharton, Diesel Engines, Butterworth-Heinemann Ltd, 1991.

↩ -

Cummins Inc., Cummins Engine Compatibility with S212 Regular Hexagon Nut, Cummins Inc., 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.