This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

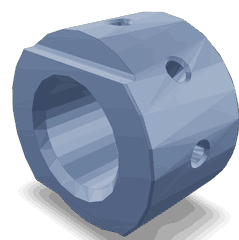

The Fracture Resistant Nut 4382667, manufactured by Cummins, is a specialized component designed to enhance the reliability and durability of commercial truck operations. Cummins, a well-established name in the automotive industry, produces this nut to meet the demanding requirements of heavy-duty applications. The significance of the 4382667 nut lies in its ability to withstand high stress and prevent failures, contributing to the overall efficiency and safety of truck operations 1.

Basic Concepts of Fracture Resistant Nuts

Fracture resistant nuts are engineered to provide enhanced durability and reliability in mechanical systems. Their primary purpose is to secure components under significant stress without succumbing to fractures or failures. These nuts are designed with materials and manufacturing processes that increase their resistance to cracking and breaking, ensuring they maintain their integrity even under extreme conditions 2.

Purpose of the 4382667 Fracture Resistant Nut in Truck Operations

The 4382667 Fracture Resistant Nut plays a specific role in the operation and maintenance of commercial trucks. It is utilized in areas where components are subjected to high stress and dynamic loads, such as in the fastening of critical engine and transmission parts. Its application ensures that these components remain securely attached, reducing the risk of unexpected failures and enhancing the overall reliability of the truck 3.

Key Features

The primary features of the 4382667 Fracture Resistant Nut include its material composition, which typically consists of high-strength alloys designed to withstand significant stress. The nut is also crafted with design elements that enhance its fracture resistance, such as precise threading and a robust construction. Unique manufacturing processes, including heat treatment and specialized coatings, further contribute to its durability and performance 4.

Benefits

Using the 4382667 Fracture Resistant Nut offers several advantages. It provides increased durability, ensuring that components remain securely fastened under high stress conditions. This reliability can lead to potential cost savings over time, as the need for frequent maintenance and replacements is reduced. Additionally, the nut’s design contributes to the overall safety and efficiency of truck operations 5.

Installation Considerations

Proper installation of the 4382667 Fracture Resistant Nut is vital to ensure its effectiveness. Guidelines and best practices include adhering to specified torque settings to achieve the correct tension without over-tightening, which could lead to damage. Compatibility with other components should also be considered to ensure a secure and reliable connection 6.

Troubleshooting Common Issues

Common problems associated with fracture resistant nuts may include loosening over time or damage due to excessive stress. Potential causes can range from incorrect installation to environmental factors. Recommended troubleshooting steps involve inspecting the nut for signs of wear or damage, ensuring proper torque settings, and addressing any underlying issues that may contribute to these problems 7.

Maintenance Tips

Routine maintenance practices are essential to ensure the longevity and performance of the 4382667 Fracture Resistant Nut. Regular inspections should be conducted to check for signs of wear, corrosion, or damage. Maintaining proper torque settings and addressing any issues promptly can help prevent failures and extend the nut’s service life 8.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality products. With a rich history of innovation and reliability, Cummins has established a strong reputation for producing durable and efficient components. The company’s commitment to quality is reflected in its product line, including the 4382667 Fracture Resistant Nut, which is designed to meet the rigorous demands of commercial truck operations 9.

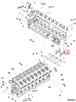

Role of Part 4382667 Fracture Resistant Nut in Engine Systems

The part 4382667 fracture resistant nut is integral to the assembly and functionality of various engine components. In the context of the cylinder block, this nut plays a significant role in securing fasteners that hold the block together. The cylinder block is the structural core of an engine, housing the cylinders, pistons, and other vital components. The fracture resistant nut ensures that the fasteners remain tightly secured, even under the extreme conditions of engine operation, such as high temperatures and vibrations 10.

When considering the cylinder block kit, the 4382667 nut is often used to assemble the various parts included in the kit. This kit typically comprises the cylinder block, gaskets, seals, and other necessary components to rebuild or repair the engine block. The fracture resistant nut is employed to fasten these components securely, ensuring that the assembly maintains integrity throughout the engine’s operational life. Its resistance to fractures and fatigue contributes to the overall reliability and durability of the engine block assembly 11.

Conclusion

The 4382667 Fracture Resistant Nut by Cummins is a critical component in enhancing the durability and reliability of commercial truck operations. Its design and material composition are tailored to withstand the high stress and dynamic loads encountered in heavy-duty applications. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part, ensuring the safety and efficiency of truck operations.

-

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.