This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3990092 Regular Hexagon Jam Nut, manufactured by Cummins, is a specialized fastener designed for use in commercial truck applications. Cummins, a well-established name in the commercial truck industry, produces this component to meet the demanding requirements of heavy-duty truck operations. This part is significant in ensuring secure fastenings in various truck systems, contributing to the overall reliability and performance of commercial vehicles.

Basic Concepts of Regular Hexagon Jam Nuts

A regular hexagon jam nut is a type of fastener characterized by its six-sided shape, which allows for efficient tightening and loosening using standard tools. The design of a jam nut involves a slightly tapered thread that, when tightened against another nut or threaded component, creates friction, thereby enhancing the security of the fastening. This type of nut is commonly used in applications where vibrations or dynamic loads are present, as it helps to prevent loosening over time 1.

Purpose of the 3990092 Regular Hexagon Jam Nut in Truck Operations

The 3990092 Regular Hexagon Jam Nut plays a role in the operation and maintenance of commercial trucks by providing secure fastenings in various systems. It is utilized in applications where components need to remain firmly attached despite the vibrations and stresses encountered during truck operation. This includes fastening critical components in the engine, transmission, and chassis systems, ensuring that parts remain securely in place, which is vital for the safe and efficient operation of the vehicle 2.

Key Features

The 3990092 Regular Hexagon Jam Nut features a hexagonal shape that facilitates easy tightening and loosening with standard wrenches or sockets. It is constructed from high-quality materials, typically steel, which provides durability and resistance to wear. The nut may also include unique design elements such as a slightly tapered thread to enhance its jamming capability, ensuring a tight and secure fit when used in conjunction with another nut or threaded component 3.

Benefits

The 3990092 Regular Hexagon Jam Nut offers several benefits in commercial truck applications. Its design enhances fastening security, making it less likely for components to loosen over time due to vibrations. The material composition ensures durability and resistance to corrosion, which is particularly important in the harsh environments often encountered by commercial trucks. Additionally, the ease of installation with standard tools simplifies maintenance procedures, reducing downtime and enhancing operational efficiency 4.

Installation and Usage

Proper installation of the 3990092 Regular Hexagon Jam Nut involves using the appropriate tools to achieve the recommended torque specifications. This ensures that the nut is tightened to the correct level, providing optimal security without over-tightening, which could damage the threads or the component being fastened. Best practices include inspecting the threads for cleanliness and proper alignment before installation to ensure a secure and lasting fastening.

Troubleshooting and Maintenance

Common issues with the 3990092 Regular Hexagon Jam Nut may include loosening due to vibrations or corrosion over time. Regular inspections can help identify these issues early, allowing for timely re-tightening or replacement as necessary. Maintenance tips include keeping the threads clean and free of debris, using thread lockers where appropriate, and ensuring that the nut is not over-tightened during installation to prevent damage.

Compatibility and Applications

The 3990092 Regular Hexagon Jam Nut is designed to be compatible with a wide range of truck makes and models, particularly those utilizing Cummins engines or components. Its applications span various truck systems and components, including but not limited to, engine mounts, transmission components, and chassis parts. This versatility makes it a valuable component in the maintenance and repair of commercial trucks.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company offers a comprehensive range of products and services designed to meet the needs of commercial vehicle operators, ensuring efficient and reliable performance in demanding applications.

Compatibility of Regular Hexagon Jam Nut 3990092 with Cummins Engines

The Regular Hexagon Jam Nut 3990092, manufactured by Cummins, is a versatile component that fits seamlessly with several of their engine models. This part is designed to provide a secure fastening solution, ensuring that bolts and screws remain tightly in place, which is crucial for the operational integrity of the engine.

G8.3 and N14 MECHANICAL Engines

The G8.3 and N14 MECHANICAL engines both benefit from the use of the 3990092 jam nut. These engines, known for their robust construction and reliability, require components that can withstand high stress and frequent adjustments. The jam nut’s design allows for easy installation and removal, making it an ideal choice for maintenance and repair tasks.

NH/NT 855 Engines

The NH/NT 855 engines also integrate the 3990092 jam nut effectively. These engines are part of Cummins’ lineup of heavy-duty diesel engines, often used in construction and agricultural machinery. The jam nut’s ability to prevent loosening under vibration and high torque conditions makes it a critical component for maintaining the structural integrity of these engines.

QSB5.9 CM850 Engines

In the QSB5.9 CM850 engines, the 3990092 jam nut plays a pivotal role in securing various components. These engines are designed for versatility, finding applications in both industrial and commercial sectors. The jam nut’s precision fit and durability ensure that the engine’s components remain securely fastened, contributing to the engine’s overall performance and longevity.

QSK60 G CM2358 K110 and QSK60G Engines

The QSK60 G CM2358 K110 and QSK60G engines are high-performance models that benefit from the use of the 3990092 jam nut. These engines are known for their power and efficiency, often used in heavy-duty applications such as mining and transportation. The jam nut’s design ensures that bolts and screws remain tightly fastened, even under extreme conditions, which is essential for the reliable operation of these engines.

By providing a secure fastening solution, the Regular Hexagon Jam Nut 3990092 enhances the reliability and performance of these Cummins engines, ensuring that they operate at peak efficiency across various applications.

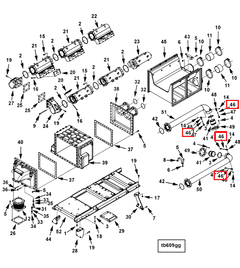

Role of Part 3990092 Regular Hexagon Jam Nut in Engine Systems

The Regular Hexagon Jam Nut, part number 3990092, is integral to the secure assembly and operation of various engine components. It ensures that connections remain tight and stable under the demanding conditions within an engine system.

In the adapter assemblies, this jam nut is used to lock the adapter fittings in place, preventing any loosening that could lead to leaks or failure of the connection. Its application here is vital for maintaining the integrity of fluid pathways.

For the rear drive components, the jam nut secures the drive shaft connections, ensuring that power transmission from the engine to other parts of the machinery is efficient and uninterrupted.

In the aftercooler system, the jam nut plays a role in securing the connections between the aftercooler and the associated piping. This ensures that the cooling process of the compressed air is effective and that there are no leaks in the system.

The control rod assemblies utilize the jam nut to maintain the precise alignment and tension required for optimal engine performance. This is particularly important in systems where the control rod must operate under varying loads and conditions.

For the cover components, such as valve covers or pump housings, the jam nut ensures that these covers are securely fastened. This prevents any unwanted access of contaminants into the engine and maintains the pressure integrity of the system.

In valve assemblies, the jam nut is employed to secure valve components, ensuring that they operate within their designed parameters without any risk of detachment or misalignment.

The filter housings often use the jam nut to secure the filter elements in place. This is essential for maintaining the filtration efficiency and preventing any bypass of contaminants.

In the oil bypass system, the jam nut secures the bypass valve and associated components, ensuring that the oil flow is managed correctly under varying engine conditions.

For the pump assemblies, whether they are fuel, water, or oil pumps, the jam nut is used to secure pump components, ensuring reliable operation and preventing any leaks that could affect pump efficiency.

In the raw water and sea water pump systems, the jam nut is critical for securing the pump housings and connections, ensuring that the cooling water flow is maintained without any interruptions.

Lastly, in the turbocharger kit, the jam nut is used to secure various turbocharger components, ensuring that the turbocharger operates efficiently and that all connections remain intact under high-pressure and high-temperature conditions.

Conclusion

The 3990092 Regular Hexagon Jam Nut is a critical component in the maintenance and operation of commercial trucks, particularly those equipped with Cummins engines. Its design and material composition ensure secure fastenings, durability, and resistance to corrosion, contributing to the overall reliability and performance of the vehicle. Proper installation, regular maintenance, and understanding its applications across various engine systems are essential for maximizing the benefits of this Cummins part.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Michael Hilgers, Chassis and Axles, Springer Vieweg, 2023.

↩ -

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Frederick F. Ling, The Automotive Body, Springer Science, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.