4976973

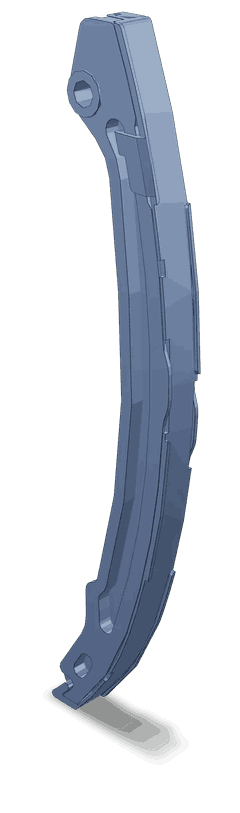

Chain Tensioner Lever

Cummins®

AVAILABLE

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction to the Cummins Chain Tensioner Lever

The Cummins Chain Tensioner Lever, identified by part number 4976973, is a critical component in the operation of commercial truck engines. This part plays a vital role in maintaining the integrity and efficiency of the engine’s timing system. Understanding its function, importance, and maintenance can significantly impact the performance and longevity of the engine 1.

Basic Concepts of a Chain Tensioner Lever

A chain tensioner lever is designed to maintain the correct tension on the timing chain, ensuring that it remains properly aligned and operates smoothly. The timing chain is responsible for synchronizing the rotation of the crankshaft and the camshaft, which in turn controls the opening and closing of the engine’s valves. Proper tension is crucial to prevent chain slippage, which can lead to severe engine damage 2.

How the Cummins Chain Tensioner Lever Works

The Cummins Chain Tensioner Lever operates by adjusting the tension on the timing chain through a mechanical linkage system. This lever is typically connected to a hydraulic tensioner or a spring-loaded mechanism that maintains consistent tension on the chain. As the engine runs, the tensioner lever ensures that the chain remains taut, preventing it from becoming loose or overly tight 3.

Purpose and Role in Truck Operations

The primary purpose of the Cummins Chain Tensioner Lever is to ensure that the timing chain maintains the correct tension, which is essential for the proper functioning of the engine. This component helps to:

- Prevent timing chain slippage, which can cause valve and piston collisions.

- Ensure efficient power transfer from the engine to the drivetrain.

- Maintain optimal engine performance and fuel efficiency.

- Extend the lifespan of the engine by reducing wear and tear on the timing components 4.

Troubleshooting and Maintenance

Proper maintenance of the Cummins Chain Tensioner Lever is crucial to avoid potential engine issues. Here are some troubleshooting tips and maintenance practices:

Troubleshooting:

- Symptoms of Failure: If the tensioner lever fails, you may notice symptoms such as a rattling noise from the engine, reduced performance, or engine misfires.

- Diagnosis: Inspect the tensioner lever for signs of wear, such as cracks or deformation. Check the tension on the timing chain and look for any visible damage to the chain or sprockets.

Maintenance:

- Regular Inspections: Periodically inspect the tensioner lever and the timing chain for signs of wear or damage. Replace any worn components immediately to prevent engine damage.

- Lubrication: Ensure that the tensioner lever and its associated components are properly lubricated to reduce friction and wear.

- Proper Adjustment: When replacing the tensioner lever, ensure that it is properly adjusted to maintain the correct tension on the timing chain.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of high-quality engine components, known for its reliability and performance. The Cummins Chain Tensioner Lever is engineered to meet the demanding requirements of commercial truck engines, providing durability and efficiency in various operating conditions.

Compatibility of Cummins Chain Tensioner Lever 4976973

The Cummins Chain Tensioner Lever part number 4976973 is designed to fit seamlessly with several engine models, ensuring optimal performance and longevity. This part is integral to maintaining the proper tension of the timing chain, which is crucial for the smooth operation of the engine.

ISV (Nissan) Engines

The Cummins Chain Tensioner Lever 4976973 is compatible with the ISV engines produced by Nissan. These engines are known for their reliability and efficiency, making them a popular choice in various applications. The part ensures that the timing chain remains properly tensioned, preventing any potential issues related to chain slack or over-tensioning.

Grouping of Compatible Engines

While the Cummins Chain Tensioner Lever 4976973 is specifically designed for the ISV engines, it is also compatible with other similar engine models that share design and engineering characteristics. This compatibility extends to engines that utilize similar chain tensioning mechanisms, ensuring that the part can be used across a range of applications without compromising performance.

Role of Part 4976973 Chain Tensioner Lever in Engine Systems

The 4976973 Chain Tensioner Lever is an integral component in maintaining the optimal performance of various engine systems. Within the Chain Drive Package, this lever ensures that the drive chain remains properly tensioned, which is essential for efficient power transmission from the Camshaft to the Front Sprocket. Proper tensioning prevents chain slack, reducing the risk of chain jump or derailment, which can lead to significant engine damage.

In the context of the Drive Chain Kit, the 4976973 lever works in conjunction with other components to maintain consistent chain tension throughout the engine’s operational range. This is particularly important in high-performance engines where the drive chain is subjected to greater stresses and higher RPMs.

The lever is also a key element in the Housing that encases the Front Gear. By keeping the chain taut, it ensures that the front gear engages smoothly with the camshaft, promoting stable and reliable engine operation.

Furthermore, in a Long Block Kit, where the engine is assembled without ancillary components, the 4976973 Chain Tensioner Lever plays a vital role in the initial setup and subsequent maintenance of the chain drive system. Its proper function is essential for the longevity and performance of the engine, ensuring that all moving parts operate within their designed parameters.

Conclusion

Understanding the Cummins Chain Tensioner Lever and its role in engine operation is essential for engineers, mechanics, truck drivers, and fleet operators. Proper maintenance and timely troubleshooting can help prevent costly engine repairs and ensure the smooth operation of commercial trucks. By adhering to recommended maintenance practices and being aware of potential issues, operators can maximize the performance and lifespan of their engines.

-

Reif, Konrad. Gasoline Engine Management Systems and Components. Springer Vieweg, 2015.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩ -

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.