This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

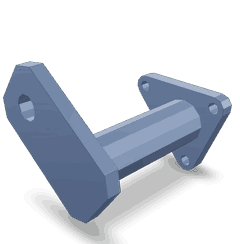

The Cummins 4913618 Idler Lever is a component designed for use in commercial trucks, contributing to the efficient operation of the vehicle’s engine or transmission system. Its design and function are integral to the smooth and reliable performance of trucks, particularly in heavy-duty applications where precision and durability are paramount.

Basic Concepts of Idler Levers

An idler lever serves as a mechanical component that redirects the motion or force within a system. In the context of a truck’s engine or transmission, it operates by adjusting the tension of belts or chains, ensuring they run smoothly and efficiently. This redirection of motion helps maintain the proper alignment and tension of moving parts, contributing to the overall functionality and longevity of the mechanical system 1.

Purpose of the Cummins 4913618 Idler Lever

This Cummins part is specifically engineered to interact with other components within a truck’s engine or transmission system. Its role involves adjusting the tension of belts or chains, which is crucial for the efficient transfer of power and the smooth operation of the engine. By maintaining the correct tension, the idler lever contributes to the truck’s performance, ensuring that the engine operates within its optimal parameters.

Key Features

The Cummins 4913618 Idler Lever is characterized by several key features that enhance its functionality and durability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring longevity in demanding environments. Additionally, the lever’s precise engineering allows for accurate tension adjustment, which is vital for the efficient operation of the truck’s engine or transmission.

Benefits of Using the Cummins 4913618 Idler Lever

Utilizing the Cummins 4913618 Idler Lever offers several advantages. Its design contributes to improved efficiency and reliability of the truck’s engine or transmission system. The lever’s ease of maintenance and durability reduce the need for frequent replacements, offering cost-effective operation over time. Furthermore, its precise function ensures optimal performance, enhancing the overall efficiency of the truck.

Installation and Integration

Proper installation of the Cummins 4913618 Idler Lever is crucial for its effective operation within a truck’s system. It is important to follow manufacturer guidelines to ensure that the lever is correctly positioned and securely fastened. This includes checking for any prerequisites or specific considerations that may affect its performance, such as alignment with other components or the condition of the belts or chains it interacts with.

Troubleshooting Common Issues

Common problems associated with idler levers can include misalignment, wear, or failure to maintain proper tension. These issues may arise from improper installation, environmental factors, or normal wear and tear. Troubleshooting steps may involve inspecting the lever for signs of damage or wear, ensuring it is correctly aligned with other components, and adjusting or replacing it as necessary to restore optimal function 2.

Maintenance Tips

Regular maintenance of the Cummins 4913618 Idler Lever is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, ensuring that it remains properly aligned and tensioned. Following manufacturer-recommended inspection intervals and care instructions can help prevent issues and ensure the lever continues to operate efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a trusted partner for commercial vehicle operators worldwide.

Cummins Idler Lever Part 4913618 Compatibility

The Cummins Idler Lever part number 4913618 is designed to fit seamlessly with several engine models, ensuring smooth operation and reliable performance. This part is crucial for maintaining the proper tension and alignment of the engine’s timing components, which is essential for the engine’s overall efficiency and longevity.

K19 Engines

The K19 engine series benefits from the precise engineering of the 4913618 Idler Lever. This part ensures that the timing chain or belt maintains the correct tension, preventing any slippage or misalignment that could lead to engine damage. The K19 engines, known for their robust design and durability, are often used in heavy-duty applications where reliability is paramount.

QSK19 and CM850 Engines

The QSK19 and CM850 engines also integrate the 4913618 Idler Lever effectively. These engines, which are part of Cummins’ high-performance lineup, require precise timing mechanisms to operate at their peak. The 4913618 Idler Lever ensures that the timing components are held in place, reducing wear and tear and enhancing the engine’s performance. These engines are typically used in demanding environments, such as construction and agricultural machinery, where consistent power and reliability are critical.

MCRS Engines

The MCRS engines, another segment of Cummins’ extensive engine portfolio, also utilize the 4913618 Idler Lever. This part is integral to the MCRS engines’ operation, ensuring that the timing system remains stable and efficient. The MCRS engines are designed for versatility and are often found in a variety of applications, from marine to industrial uses, where they need to perform reliably under diverse conditions.

By ensuring that the 4913618 Idler Lever is correctly installed and maintained, operators of these engines can expect improved performance, reduced maintenance costs, and longer engine life. This part’s compatibility across multiple engine models underscores its importance in the Cummins engine ecosystem.

Role of Part 4913618 Idler Lever in Engine Systems

The 4913618 Idler Lever is an integral component in the operation of various engine systems, particularly those involving the drive and fan mechanisms.

In systems where a drive mechanism is present, the 4913618 Idler Lever facilitates the smooth transfer of motion from the engine to other components. It acts as a mediator, ensuring that the rotational force generated by the engine is efficiently transmitted. This is essential for the consistent operation of parts that rely on this drive, such as pumps, compressors, or other auxiliary systems connected to the engine.

When it comes to fan systems, the 4913618 Idler Lever plays a significant role in maintaining the optimal performance of the cooling fan. By adjusting the tension and alignment of the fan belt, it ensures that the fan operates at the required speed to provide adequate cooling for the engine. This is particularly important in preventing overheating, which can lead to engine damage.

Overall, the 4913618 Idler Lever is a key component in ensuring the reliable and efficient operation of both drive and fan systems within an engine. Its proper function is essential for the seamless integration and performance of these critical engine components.

Conclusion

The Cummins 4913618 Idler Lever is a vital component in the efficient operation of commercial truck engines and transmission systems. Its role in maintaining the proper tension and alignment of belts and chains ensures the smooth and reliable performance of the engine. By understanding its function, benefits, and maintenance requirements, operators can enhance the efficiency and longevity of their vehicles. Proper installation, regular maintenance, and timely troubleshooting of common issues are essential practices to maximize the performance and lifespan of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.