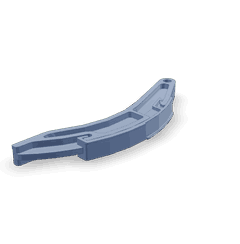

4325539

Chain Tensioner Lever

Cummins®

DISCONTINUED

More than 10 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4325539 Chain Tensioner Lever is a component designed to maintain the proper tension of chains within the mechanical systems of commercial trucks. Its role is vital for ensuring the smooth and efficient operation of the truck’s engine and related components.

Basic Concepts of Chain Tensioner Levers

A Chain Tensioner Lever is a mechanical device that adjusts the tension of chains used in various engine components. It operates by applying force to keep the chain taut, which is important for the efficient transfer of power and the reduction of wear on the chain and sprockets. Maintaining proper chain tension is important for the longevity and performance of the mechanical system 1.

Purpose and Role in Truck Operation

This Cummins part is specifically designed to ensure that the chains within a truck’s engine maintain the correct tension. This is achieved through a mechanism that allows for adjustment as the chain stretches over time. Proper tensioning prevents issues such as chain slippage, increased wear on engine components, and potential engine damage. The lever plays a role in maintaining optimal chain tension, which contributes to the overall efficiency and reliability of the truck’s operation 2.

Key Features

The Cummins 4325539 is characterized by its robust design and the use of high-quality materials, which enhance its durability and performance. The lever is engineered to withstand the rigors of commercial truck operation, ensuring consistent tension adjustment. Its design includes features that facilitate easy adjustment and maintenance, contributing to the overall reliability of the truck’s mechanical system.

Benefits

Utilizing the Cummins 4325539 offers several advantages, including improved engine performance due to optimal chain tension. It also reduces wear and tear on chains and sprockets, leading to extended component life. Additionally, the lever contributes to the enhanced reliability of the truck’s mechanical system by ensuring that chains operate within their designed parameters 3.

Installation Process

Installing the Cummins 4325539 requires following a step-by-step process to ensure proper function and safety. The process involves securing the lever in place, adjusting it to the correct tension, and verifying its operation. Tools and equipment specific to the model may be required, and safety precautions should be observed to prevent injury and ensure the lever is installed correctly.

Troubleshooting Common Issues

Common problems associated with Chain Tensioner Levers include improper tension adjustment, wear, and malfunction. Addressing these issues involves inspecting the lever for signs of damage or wear, adjusting the tension as necessary, and replacing the lever if it is found to be faulty. Recognizing these signs early can prevent more significant problems and ensure the continued efficient operation of the truck.

Maintenance Tips

Regular maintenance of the Cummins 4325539 is important for its longevity and performance. This includes periodic inspection for wear or damage, cleaning to remove dirt and debris, and lubrication of moving parts to reduce friction and wear. Adhering to recommended maintenance intervals and procedures ensures the lever continues to function effectively, contributing to the overall reliability of the truck’s mechanical system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s commitment to quality and innovation is evident in its wide range of products, including the Cummins 4325539, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Chain Tensioner Lever 4325539 Compatibility

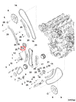

The Cummins Chain Tensioner Lever 4325539 is a component designed to maintain proper tension in the timing chain of various engines. This part ensures that the timing chain operates smoothly and efficiently, preventing potential engine damage due to improper chain tension.

ISV (Nissan) Engines

The Cummins Chain Tensioner Lever 4325539 is compatible with several ISV (Nissan) engines. This compatibility ensures that the tensioner lever can effectively manage the timing chain tension in these engines, contributing to their overall performance and longevity.

Engine Group: ISV Series

- ISV450

- ISV550

- ISV650

These engines benefit from the precise tension management provided by the Cummins Chain Tensioner Lever 4325539, ensuring optimal engine operation and reliability.

Role of Part 4325539 Chain Tensioner Lever in Engine Systems

The 4325539 Chain Tensioner Lever is an integral component in maintaining the optimal performance of various engine systems. Its primary function is to ensure the proper tension of the chain within the chain drive package, which is essential for the efficient transfer of power from the engine to the driven components.

Integration with Chain Drive Package

Within the chain drive package, the 4325539 Chain Tensioner Lever works in conjunction with the chain to maintain consistent tension. This is vital for preventing chain slack, which can lead to inefficient power transmission and increased wear on the chain and sprockets. The tensioner lever automatically adjusts to keep the chain taut, ensuring smooth and reliable operation of the drive system.

Interaction with the Drive and Front Sprocket

The drive system relies on the front sprocket to transmit power from the engine to the chain. The 4325539 Chain Tensioner Lever plays a significant role here by ensuring that the chain remains properly tensioned against the front sprocket. This tension is necessary for the sprocket to grip the chain effectively, thereby facilitating a consistent and powerful drive. Without proper tension, the chain may skip teeth on the sprocket, leading to a loss of power and potential damage to the drive components.

Role in the Long Block Kit

In a long block kit, which typically includes the engine block, crankshaft, pistons, and other essential components, the 4325539 Chain Tensioner Lever ensures that the chain drive system operates within specified parameters. This is particularly important during the initial setup and subsequent maintenance of the engine. Proper chain tension is essential for the longevity and performance of the engine components, especially in high-stress environments where precision and reliability are paramount.

Contribution to the Upper Engine Gasket Kit

Although the upper engine gasket kit primarily focuses on sealing components such as the cylinder head, intake manifold, and exhaust manifold, the 4325539 Chain Tensioner Lever indirectly supports this system by maintaining chain tension. A well-tensioned chain reduces the likelihood of misalignment or excessive movement, which can otherwise lead to gasket failures or compromised seals. This, in turn, helps in maintaining the integrity of the upper engine components and ensures a leak-free operation.

Conclusion

In summary, the 4325539 Chain Tensioner Lever is a key component that enhances the functionality and reliability of various engine systems by ensuring that the chain drive remains properly tensioned. This not only optimizes power transmission but also contributes to the overall durability and performance of the engine 4.

-

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Williams, D. (2022). Generalized Vehicle Dynamics. SAE International.

↩ -

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.