This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

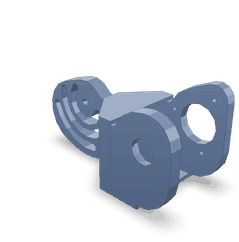

The Cummins 4016907 Idler Lever is a specialized component designed for commercial trucks, playing a crucial role in the engine or transmission system. Understanding its function and importance is essential for maintaining the efficiency and reliability of these vehicles.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that facilitates the movement or redirection of force within a system. In truck engines or transmissions, it adjusts or maintains tension in belts or chains, ensuring smooth operation and longevity of interacting components. Its operation involves pivoting on a fixed point to apply or relieve tension as needed 1.

Purpose of the 4016907 Idler Lever

This Cummins part is designed to interact with other components within a truck’s engine or transmission system. Its role includes adjusting tension in belts or chains, which is vital for efficient power transfer and reducing wear on moving parts. By maintaining optimal tension, the idler lever contributes to the truck’s performance, ensuring smooth and efficient engine operation 2.

Key Features

The 4016907 Idler Lever is characterized by its robust design and durable construction materials. It is engineered to withstand the demanding conditions of commercial truck operations, featuring precision engineering for accurate tension adjustment and a design that minimizes maintenance requirements 3.

Benefits of Using the 4016907 Idler Lever

Incorporating this part into a truck’s system offers several advantages. It contributes to improved efficiency by ensuring that belts or chains operate within their optimal tension range, reducing the risk of slippage or excessive wear. The reliability of the 4016907 Idler Lever enhances the overall performance of the truck, providing a component that operators can depend on for consistent operation 4.

Installation and Integration

Installing the 4016907 Idler Lever involves integrating it into the truck’s engine or transmission system according to manufacturer guidelines. Proper installation requires attention to prerequisites such as correct alignment and secure mounting to ensure the idler lever functions as intended. Considerations for installation may include verifying compatibility with the truck’s make and model and following specific torque settings for fasteners.

Troubleshooting Common Issues

Frequent problems associated with the 4016907 Idler Lever may include issues with tension adjustment or wear on the lever itself. Potential causes for these problems can range from incorrect installation to normal wear and tear over time. Recommended solutions or adjustments may involve realigning the idler lever, replacing worn components, or adjusting the tension according to manufacturer specifications.

Maintenance Tips

Routine maintenance of the 4016907 Idler Lever is key to ensuring its longevity and optimal performance. Maintenance practices may include regular inspection intervals to check for signs of wear or damage, ensuring that the idler lever remains properly aligned and tensioned. Care procedures should follow manufacturer recommendations to preserve the integrity of the component and the efficiency of the truck’s engine or transmission system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins has established a reputation for quality and reliability in the commercial truck industry. The 4016907 Idler Lever, as part of their product offering, reflects the company’s commitment to providing components that enhance the performance and durability of commercial vehicles.

Role of Part 4016907 Idler Lever in Engine Systems

The 4016907 Idler Lever is an integral component in the operation of various engine systems, particularly those involving the drive and fan mechanisms. Its primary function is to facilitate the tensioning and alignment of the idler shaft, which in turn ensures the smooth and efficient operation of the drive belt.

In engine systems, the drive belt is responsible for transferring power from the engine to various components, such as the fan. The idler lever plays a significant role in maintaining the correct tension on the drive belt. This tension is vital for the belt to grip the pulleys effectively, ensuring that power is transmitted efficiently without slippage.

The idler lever works in conjunction with the idler shaft. The idler shaft is positioned between the engine-driven pulley and the fan pulley. Its role is to support the drive belt and help in maintaining the proper belt path. The 4016907 Idler Lever adjusts the position of the idler shaft, allowing for precise tensioning of the belt. This adjustment is necessary during the installation process and throughout the operational life of the engine to account for wear and changes in belt length.

Additionally, the idler lever contributes to the stability and reliability of the fan operation. The fan, which is often belt-driven, relies on consistent and adequate belt tension to function correctly. The 4016907 Idler Lever ensures that the fan receives the necessary power transmission, enabling it to operate at optimal efficiency. This is particularly important in engines where the fan is responsible for cooling critical components, ensuring that the engine maintains safe operating temperatures.

Conclusion

The 4016907 Idler Lever is a key component in the interplay between the drive belt, idler shaft, and fan within engine systems. Its role in tensioning and aligning these components is essential for the overall performance and reliability of the engine. Regular maintenance and proper installation are crucial to ensure the longevity and efficiency of this part in commercial truck operations.

-

Fehan, D. R. (2013). Design of Racing and High-Performance Engines 2004-2013. SAE International.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ -

Wright, G. (2015). Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.