This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

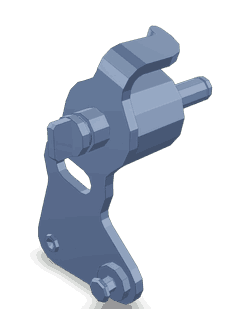

The Bell Crank Lever, part number 3931560, manufactured by Cummins, is a critical component in the engine systems of various Cummins engines, including the 6B5.9. This part is integral to the engine’s operation, facilitating the transfer of motion and force between different parts of the engine.

Basic Concepts of Bell Crank Levers

A Bell Crank Lever is a type of lever that changes the direction of a force applied to it. It operates on the principle of mechanical advantage, allowing for the transmission of force in a perpendicular direction. This lever consists of a pivot point and two arms, one of which receives the input force while the other delivers the output force at a right angle. In automotive applications, Bell Crank Levers are often used to convert linear motion into rotational motion or vice versa, facilitating the operation of various systems 1.

Purpose of the Bell Crank Lever 3931560

The Bell Crank Lever 3931560 is specifically designed to play a role in the operation of commercial trucks. It is utilized in systems where a change in the direction of force is required, such as in braking systems or clutch mechanisms. This lever ensures that the force applied is efficiently transmitted and converted, contributing to the smooth operation of the truck’s mechanical systems 2.

Key Features

The Bell Crank Lever 3931560 is characterized by its robust design and high-quality materials. It is constructed from durable metals that can withstand the rigors of commercial truck use. The lever features precise machining for accurate force transmission and is designed to integrate seamlessly with other components in the truck’s system. Its unique attributes include a corrosion-resistant coating and a design that minimizes wear and tear, enhancing its performance and longevity 3.

Benefits

The advantages of the Bell Crank Lever 3931560 include improved efficiency in force transmission, enhanced durability under demanding conditions, and reliable performance. Its design contributes to the overall efficiency of the truck’s mechanical systems, ensuring that operations are smooth and consistent. The lever’s durability means it can withstand the stresses of commercial use, reducing the need for frequent replacements and maintenance 4.

Installation and Integration

Installing the Bell Crank Lever 3931560 involves securing it to the appropriate mounting points within the truck’s system. It is important to ensure that all connections are tight and that the lever is aligned correctly to function as intended. Integration into the truck’s system may require adjustments to other components to accommodate the lever’s operation. Following the manufacturer’s guidelines for installation is recommended to ensure proper function and safety 5.

Common Issues and Troubleshooting

Typical problems associated with the Bell Crank Lever 3931560 may include misalignment, wear on the pivot point, or damage to the lever arms. Troubleshooting steps involve checking the alignment of the lever, inspecting for signs of wear or damage, and ensuring that all connections are secure. Solutions may include realigning the lever, replacing worn components, or tightening connections as necessary.

Maintenance Tips

To ensure the longevity and optimal performance of the Bell Crank Lever 3931560, regular maintenance is recommended. This includes inspecting the lever for signs of wear or damage, ensuring that all connections are tight, and cleaning the lever to remove any debris that may affect its operation. Following a routine maintenance schedule can help prevent issues and ensure that the lever continues to function efficiently.

Safety Considerations

When working with the Bell Crank Lever 3931560, it is important to observe safety guidelines to protect mechanics and operators. This includes wearing appropriate personal protective equipment, ensuring that the truck is securely parked and the engine is off before beginning work, and following all manufacturer’s safety recommendations. Proper handling and installation of the lever are crucial to avoid accidents and ensure safe operation.

Cummins Overview

Cummins is a leading manufacturer in the automotive industry, with a history of producing high-quality, innovative parts for commercial vehicles. The company is known for its commitment to quality, reliability, and customer satisfaction. Cummins’ reputation in the industry is built on a foundation of engineering excellence and a dedication to meeting the needs of its customers with products that deliver performance and durability 6.

Role of Part 3931560 Bell Crank Lever in Engine Systems

In engine systems, the Bell Crank Lever (part 3931560) is integral to the operation of several key components, ensuring smooth and efficient functionality.

Interaction with the Throttle

The Bell Crank Lever is designed to interact directly with the throttle mechanism. When the throttle is adjusted, either manually or through an automated system, the Bell Crank Lever translates this movement into a mechanical action. This action is essential for controlling the airflow into the engine, which in turn regulates the engine’s power output.

Connection to the Throttle Bracket

The throttle bracket serves as a mounting point for the throttle assembly. The Bell Crank Lever connects to this bracket, allowing for precise control over the throttle’s position. This connection ensures that the throttle can be adjusted accurately, which is vital for maintaining the desired engine performance under varying conditions.

Integration with the Throttle Kit

In many engine systems, a throttle kit is used to simplify the installation and adjustment of the throttle components. The Bell Crank Lever is a key part of this kit, providing the necessary leverage and mechanical advantage to operate the throttle effectively. Its integration within the throttle kit ensures that all components work in harmony, offering a seamless user experience.

Overall Functionality

By linking the throttle, throttle bracket, and throttle kit, the Bell Crank Lever plays a significant role in the overall functionality of the engine system. It ensures that the throttle can be adjusted with precision, allowing for optimal engine performance. This component is essential for maintaining the balance between airflow and fuel delivery, which is fundamental to the engine’s operation.

Conclusion

The Bell Crank Lever 3931560 is a vital component in the operation of Cummins engines, particularly in the 6B5.9 model. Its role in converting rotational motion into linear motion is crucial for the proper functioning of the engine’s valve train. The lever’s design and integration into the engine’s architecture are testament to Cummins’ commitment to quality and reliability in their engine components. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this part.

-

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Dempsey, P. (2018). Troubleshooting and Repairing Diesel Engines, 5th Edition. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Owners Manual for B6.7 G CMOH6.0 B125, Bulletin Number 4383642.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins Official Website.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.