This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

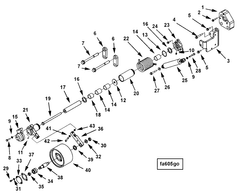

The Cummins 3638483 Idler Lever is a component designed for use in commercial trucks, specifically within the K50, QSK60 CM500, and QSK60 CM850 MCRS engines. It plays a role in maintaining the correct tension on belts or chains, ensuring efficient power transmission and reducing the risk of slippage or misalignment 1. Understanding its purpose and significance is key to maintaining and optimizing truck functionality.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that facilitates the movement or redirection of force within a system. In commercial trucks, idler levers are often used in conjunction with belts or chains to maintain tension, ensure proper alignment, and distribute load evenly across the system 2. The Cummins 3638483 Idler Lever is tailored to meet the demands of heavy-duty applications, ensuring reliable operation under various conditions.

Purpose of the Cummins 3638483 Idler Lever

This Cummins part is integral to the truck’s mechanical system, maintaining the correct tension on belts or chains. Its interaction with other components, such as pulleys and tensioners, contributes to the smooth operation of the truck, enhancing overall performance and reliability 3.

Key Features

The Cummins 3638483 Idler Lever is characterized by its robust design and construction. It is made from high-quality materials that offer durability and resistance to wear. The lever’s build quality ensures it can withstand the rigors of commercial truck operation. Unique characteristics, such as its precise engineering and compatibility with specific truck models, distinguish it from other idler levers on the market.

Benefits of Using the Cummins 3638483 Idler Lever

Incorporating this part into a truck’s system offers several advantages. It contributes to improved efficiency by ensuring optimal belt or chain tension, which can lead to better fuel economy and reduced maintenance costs. The lever’s durability and reliability mean it requires less frequent replacement, providing long-term value to truck operators.

Installation and Integration

Proper installation of the Cummins 3638483 Idler Lever is crucial for ensuring compatibility and optimal performance. It is important to follow manufacturer guidelines to ensure the lever is correctly positioned and secured. This may involve checking for proper alignment with other components and ensuring all fasteners are tightened to the specified torque.

Troubleshooting Common Issues

Common problems associated with idler levers include noise, vibration, and premature wear. These issues can often be traced back to incorrect installation, misalignment, or lack of maintenance. Troubleshooting steps may involve inspecting the lever and related components for signs of wear or damage, ensuring proper alignment, and making adjustments as necessary.

Maintenance Tips

Regular maintenance is key to ensuring the longevity and efficient operation of the Cummins 3638483 Idler Lever. This includes periodic inspections for signs of wear, ensuring proper tension is maintained, and cleaning the lever and surrounding components to prevent buildup of dirt or debris. Following these practices can help prevent issues and ensure the lever continues to perform effectively.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is renowned for its expertise in diesel engine manufacturing and its commitment to innovation and quality. The company’s products are designed to meet the demanding requirements of various industries, including commercial trucking, where reliability and performance are paramount 4.

Conclusion

The Cummins 3638483 Idler Lever is a vital component in the engine systems of the K50, QSK60 CM500, and QSK60 CM850 MCRS engines. Its role in maintaining belt tension ensures efficient power transmission, contributing to the overall performance and reliability of these engines. Proper installation, regular maintenance, and understanding its function are essential for maximizing the benefits of this Cummins part.

-

Hilgers, Michael. The Drivers Cab. Springer Vieweg, 2022.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing, 2002.

↩ -

Cummins Inc. ISX12N CM2380 X120B, Bulletin Number 5504154, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.