3177130

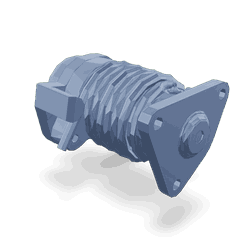

Idler Lever

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3177130 Idler Lever is a critical component for heavy-duty trucks, designed to enhance the efficiency and performance of the vehicle’s engine or transmission system. Understanding its function and operation is essential for maintaining and optimizing heavy-duty truck performance.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that facilitates the movement or redirection of force within a system. In heavy-duty trucks, it typically adjusts or maintains tension in belts or chains, ensuring smooth operation and longevity of the components it interacts with. The lever operates by pivoting on a fixed point, altering the direction or magnitude of force applied to other parts of the system 1.

Purpose of the Cummins 3177130 Idler Lever

This Cummins part is designed to interact with other components within a truck’s engine or transmission system. Its primary role is to adjust the tension of belts or chains, which is crucial for the efficient transfer of power and the smooth operation of the engine. By maintaining proper tension, the idler lever contributes to the overall performance and reliability of the truck 2.

Key Features

The Cummins 3177130 Idler Lever is characterized by several key features. It is constructed from high-quality materials, ensuring durability and resistance to wear. The design includes precise engineering for smooth operation and efficient force transmission. Additionally, it may feature corrosion-resistant coatings or specialized pivot points to enhance functionality and longevity in demanding environments 3.

Benefits of Using the Cummins 3177130 Idler Lever

Utilizing this part in heavy-duty truck applications offers several advantages. Its high-quality construction and precise engineering contribute to improved efficiency and reliability of the truck’s engine or transmission system. The lever’s design ensures smooth operation, reducing the likelihood of mechanical failures and enhancing overall vehicle performance.

Installation and Integration

Proper installation of the Cummins 3177130 Idler Lever is crucial for its effective operation within a truck’s engine or transmission system. Installation guidelines typically include ensuring the lever is correctly aligned and securely fastened to prevent movement or misalignment. It is also important to verify that the lever interacts properly with other components, such as belts or chains, to maintain the desired tension and operation.

Troubleshooting Common Issues

Common issues with the Cummins 3177130 Idler Lever may include misalignment, wear, or failure to maintain proper tension. Diagnostic steps for addressing these issues involve inspecting the lever for signs of damage or wear, ensuring it is correctly aligned and fastened, and verifying its interaction with other components. Solutions may range from simple adjustments to replacement of the lever if it is found to be damaged or worn.

Maintenance Tips

Routine maintenance of the Cummins 3177130 Idler Lever is important for ensuring its longevity and optimal performance. Maintenance practices may include regular inspection for signs of wear or damage, ensuring proper alignment and tension, and lubrication of pivot points to reduce friction and wear. Adhering to recommended inspection intervals and maintenance procedures can help prevent issues and ensure the lever continues to operate efficiently.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a reputation for reliability and performance in the automotive and heavy-duty truck industry. The company’s product range includes a variety of components and systems designed to enhance the efficiency, reliability, and performance of vehicles and equipment. The Cummins 3177130 Idler Lever is a testament to the company’s commitment to quality and excellence in engineering.

Compatibility with Cummins Engines

The Idler Lever part number 3177130, manufactured by Cummins, is designed to fit a variety of Cummins engines. This part is integral to the engine’s operation, ensuring smooth and efficient functioning. Below is a detailed look at the compatibility of this idler lever with specific Cummins engines:

GTA38 G CMEICS G116C

The GTA38 G CMEICS G116C engine is one of the models that can utilize the 3177130 Idler Lever. This engine is known for its robust design and reliability, making it a popular choice in various applications. The idler lever ensures that the engine’s components operate smoothly, reducing wear and tear.

K38, K50, QSK38 CM2150 MCRS, QSK38 CM850 MCRS

The Idler Lever 3177130 is also compatible with the K38, K50, QSK38 CM2150 MCRS, and QSK38 CM850 MCRS engines. These engines are part of Cummins’ QSK series, which is renowned for its high performance and durability. The idler lever plays a crucial role in maintaining the balance and efficiency of these engines, ensuring they run smoothly under various conditions.

QST30 CM552

Lastly, the QST30 CM552 engine is another model that can use the 3177130 Idler Lever. This engine is designed for applications that require a balance of power and efficiency. The idler lever in this context helps in maintaining the smooth operation of the engine, contributing to its overall performance and longevity.

Role of Part 3177130 Idler Lever in Engine Systems

The 3177130 Idler Lever is a pivotal component in the orchestration of various engine systems, particularly those involving the fan and radiator cooling mechanisms. Its primary function is to facilitate the smooth operation of the fan drive arrangement by ensuring that the fan idler assembly operates efficiently.

In the context of the drive system, the 3177130 Idler Lever plays a significant role in maintaining the correct tension and alignment of the fan drive belt. This is vital for the consistent operation of the fan, which is responsible for drawing air through the radiator to cool the engine. The idler lever ensures that the belt remains taut, preventing slippage that could lead to inefficient cooling or complete failure of the fan drive.

The fan arrangement is another area where the 3177130 Idler Lever is instrumental. By controlling the position and movement of the idler assembly fan, it allows for the precise adjustment of the fan’s engagement with the drive belt. This adjustment is necessary to accommodate varying engine speeds and cooling requirements, ensuring that the fan operates only when needed to conserve energy and reduce wear on the engine components.

Furthermore, the idler lever is integral to the radiator cooling system. It helps in modulating the fan’s speed and operation in response to the engine’s temperature, as detected by the thermostat or temperature sensor. This dynamic adjustment is key to maintaining optimal engine temperature, preventing overheating, and ensuring the longevity of the engine and its components.

Conclusion

In summary, the 3177130 Idler Lever is a critical component in the interplay between the drive, fan, and radiator cooling systems. Its role in maintaining belt tension, adjusting fan engagement, and contributing to efficient radiator cooling underscores its importance in the overall functionality and reliability of engine systems.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems Fifth Edition. Delmar Cengage Learning.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.