The Cummins 3094907 Idler Lever is a component designed for use in heavy-duty trucks. It serves a specific function within the truck’s mechanical system, contributing to the overall operation and performance of the vehicle. Understanding its role and significance can provide valuable insights into the complexities of heavy-duty truck mechanics.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that facilitates the movement and operation of other parts within a system. In the context of heavy-duty trucks, the idler lever interacts with the clutch system, assisting in the engagement and disengagement of the clutch. This interaction allows for smooth gear changes and efficient power transmission from the engine to the drivetrain 1.

Purpose of the Cummins 3094907 Idler Lever

This Cummins part plays a role in the truck’s operation by ensuring the proper function of the clutch system. It is involved in the mechanism that allows the driver to shift gears seamlessly. The lever’s design and placement enable it to apply the necessary force and movement to the clutch components, impacting the truck’s driving performance and the ease with which the driver can operate the vehicle 2.

Key Features

The 3094907 is characterized by its robust design and the materials used in its construction. It is engineered to withstand the rigors of heavy-duty truck operation, featuring a durable build that ensures longevity and reliable performance. The lever’s design may include specific attributes that enhance its functionality, such as precise engineering for optimal force application and smooth operation within the clutch system 3.

Benefits of Using the Cummins 3094907 Idler Lever

Incorporating this part into a truck’s system offers several advantages. It contributes to the efficiency of the clutch system, allowing for smoother gear changes and improved driving dynamics. The lever’s durable construction ensures it can withstand the demands of heavy-duty use, providing long-term reliability. Additionally, its design may facilitate easier maintenance, reducing downtime and repair costs for truck operators.

Installation Process

Installing the 3094907 requires careful attention to detail and adherence to safety protocols. The process involves disconnecting the battery to prevent electrical accidents, removing the old idler lever, and installing the new one in its place. Specific tools may be required, and it is important to follow the manufacturer’s instructions to ensure proper installation. Safety precautions, such as wearing protective gear and ensuring the truck is securely supported, should be observed throughout the process.

Troubleshooting Common Issues

Idler levers, including the 3094907, may encounter issues over time. Common problems can include wear and tear, misalignment, or failure to engage properly. Diagnosing these issues involves inspecting the lever and its interaction with the clutch system. Solutions may range from simple adjustments to replacement of the lever or other components. Regular maintenance and inspections can help identify potential issues before they lead to significant problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3094907, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, ensuring proper alignment and operation within the clutch system, and cleaning the lever and surrounding components to prevent buildup that could affect performance. Adhering to manufacturer-recommended inspection intervals and maintenance procedures will help maintain the lever’s efficiency and reliability.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the manufacture of diesel engines and related components. The company’s product range includes a variety of engines and parts designed for heavy-duty applications, reflecting its commitment to meeting the needs of its customers with reliable and efficient solutions.

Idler Lever Part 3094907 Compatibility with Cummins Engines

The Idler Lever part 3094907, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is crucial for the proper functioning of the engine’s belt drive system, ensuring that the belt maintains the correct tension and alignment.

QST30 CM552 Engines

The Idler Lever part 3094907 is specifically engineered to integrate with the QST30 CM552 engines. This compatibility ensures that the idler lever’s design aligns with the unique specifications and requirements of these engines, providing a reliable and efficient solution for maintaining belt tension.

Grouping of Compatible Engines

While the Idler Lever part 3094907 is explicitly designed for the QST30 CM552 engines, it is also compatible with other Cummins engines that share similar design characteristics and belt drive systems. This grouping ensures that the idler lever can be used across a broader range of Cummins engines, providing a versatile solution for maintenance and repair needs.

By ensuring that the Idler Lever part 3094907 fits with the QST30 CM552 engines and other compatible Cummins engines, Cummins maintains a high standard of quality and reliability in their engine components. This compatibility is essential for technicians and engineers who rely on these parts for efficient engine operation and maintenance.

Role of Part 3094907 Idler Lever in Engine Systems

The 3094907 Idler Lever is an essential component in the coordination and efficient operation of various engine systems. Its primary function is to regulate the tension within the fan drive system, ensuring smooth and consistent performance.

Interaction with the Drive System

In the drive system, the 3094907 Idler Lever works in conjunction with the drive belt to maintain optimal tension. This is vital for the efficient transfer of power from the engine to the fan. Proper tension ensures that the drive belt does not slip, which could lead to inefficient cooling and increased wear on the belt and pulleys.

Coordination with the Fan

The fan is a key component in engine cooling, and the 3094907 Idler Lever plays a significant role in its operation. By adjusting the tension on the drive belt, the Idler Lever helps to ensure that the fan operates at the correct speed. This is particularly important under varying engine loads and temperatures, as the fan speed needs to be dynamically adjusted to maintain optimal cooling.

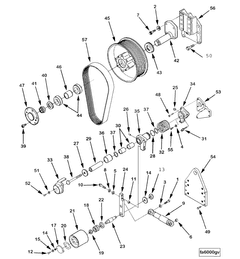

Integration with the Idler Assembly

The idler assembly is designed to maintain the proper alignment and tension of the drive belt. The 3094907 Idler Lever is a critical part of this assembly, allowing for fine-tuned adjustments. This ensures that the belt remains in the correct position on the pulleys, reducing the risk of misalignment and subsequent damage to the belt or pulleys.

Overall System Efficiency

By ensuring that the drive belt is properly tensioned and aligned, the 3094907 Idler Lever contributes to the overall efficiency of the engine cooling system. This not only enhances the performance of the engine but also extends the lifespan of the components involved. The Idler Lever’s role in maintaining consistent belt tension is fundamental to the reliable operation of the fan drive system.

Conclusion

The Cummins 3094907 Idler Lever is a critical component in the operation of heavy-duty trucks, particularly in the efficient functioning of the clutch and fan drive systems. Its robust design, compatibility with a range of Cummins engines, and the benefits it offers in terms of performance and reliability make it a valuable part for truck operators and mechanics alike. Regular maintenance and proper installation are key to ensuring the longevity and optimal performance of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.