This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

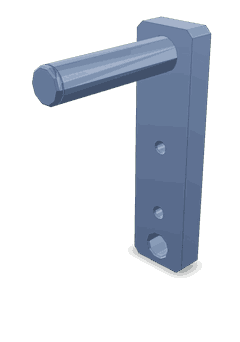

The Cummins 3092159 Idler Lever is a component designed for use in commercial trucks. It serves a specific function within the truck’s engine or transmission system, contributing to the overall operation and performance of the vehicle. Understanding its purpose and significance can help in maintaining and optimizing the truck’s functionality.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that plays a role in redirecting or maintaining tension within a system. In the context of a truck’s engine or transmission, it typically assists in the operation of belts or chains by providing a pivot point or adjusting tension. This ensures smooth and efficient operation of the connected components 1.

Purpose of the Cummins 3092159 Idler Lever

The Cummins 3092159 Idler Lever is specifically designed to interact with other components within a truck’s engine or transmission system. Its role includes maintaining proper tension and alignment of belts or chains, which is vital for the efficient transfer of power and the smooth operation of various engine functions. By ensuring that these elements are correctly positioned and tensioned, the idler lever contributes to the truck’s overall performance and reliability 2.

Key Features

The Cummins 3092159 Idler Lever is characterized by its robust design and the use of high-quality materials. These features ensure durability and reliable performance under the demanding conditions typical of commercial truck operations. The lever’s design may include specific mounting points, adjustment mechanisms, and a shape that allows for optimal interaction with other components. These characteristics distinguish it from other idler levers, providing enhanced functionality and longevity 3.

Benefits

Utilizing the Cummins 3092159 Idler Lever offers several advantages. Its design and material properties contribute to improved efficiency in the engine or transmission system, reducing the likelihood of wear and tear on connected components. The lever’s durability ensures long-term performance, minimizing the need for frequent replacements. Additionally, its precise engineering allows for easy installation and adjustment, facilitating maintenance and repair processes 4.

Installation Process

Installing the Cummins 3092159 Idler Lever requires careful attention to ensure proper fitting and functionality. The process involves securing the lever in its designated position within the engine or transmission system, making any necessary adjustments to tension or alignment. Tools and equipment required may include wrenches for tightening bolts and a tension gauge to ensure correct belt or chain tension. It is important to follow manufacturer guidelines to ensure the lever is installed correctly and operates as intended.

Troubleshooting Common Issues

Common problems with the Cummins 3092159 Idler Lever may include misalignment, excessive wear, or failure to maintain proper tension. Troubleshooting these issues involves inspecting the lever and its connections for signs of damage or wear, adjusting the tension as necessary, and ensuring that all components are correctly aligned. In some cases, replacement of the lever or related parts may be required to restore optimal performance.

Maintenance Tips

Regular maintenance of the Cummins 3092159 Idler Lever is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, adjusting tension as needed, and cleaning the lever and its surroundings to prevent buildup of dirt or debris. Following manufacturer recommendations for inspection intervals and care instructions will help maintain the lever’s functionality and contribute to the overall efficiency of the truck’s engine or transmission system.

Compatibility with Cummins Engines

The Idler Lever part number 3092159, manufactured by Cummins, is designed to fit seamlessly with several of their engine models. This part plays a role in the engine’s operation by managing the tension of the timing belt or chain, ensuring smooth and efficient engine performance.

QST30 CM2350 T101 and QST30 CM552

The Idler Lever part 3092159 is compatible with the QST30 CM2350 T101 and QST30 CM552 engines. These engines are part of the Cummins QST series, known for their reliability and robust performance in various applications. The idler lever’s design ensures that it fits precisely into the engine’s timing mechanism, maintaining the correct tension and alignment of the timing belt or chain. This compatibility is important for preventing wear and tear on the engine components, thereby extending the engine’s lifespan and maintaining optimal performance.

Grouping of Compatible Engines

While the Idler Lever part 3092159 is specifically designed to fit the QST30 CM2350 T101 and QST30 CM552 engines, it is important to note that Cummins often designs parts to be compatible across multiple engine models within the same series. This design philosophy ensures that technicians and mechanics can easily find and use parts that fit their specific engine needs, reducing downtime and maintenance costs.

Role of Part 3092159 Idler Lever in Engine Systems

The 3092159 Idler Lever is an integral component in the operation of various engine systems, particularly those involving the fan drive and idler assemblies. Its primary function is to facilitate the smooth and efficient transfer of mechanical power from the engine to the fan, ensuring optimal cooling performance.

Interaction with the Drive System

In the drive system, the 3092159 Idler Lever works in conjunction with the idler pulley to maintain tension in the drive belt. This tension is essential for the efficient transfer of power from the engine to the fan. Without proper tension, the drive belt may slip, leading to inefficient power transfer and potential overheating of the engine.

Coordination with the Fan and Fan Drive Idle Assembly

The 3092159 Idler Lever plays a significant role in the fan and fan drive idle assembly. It helps in adjusting the position of the fan drive idler assembly, which in turn controls the engagement and disengagement of the fan drive. This adjustment is vital for maintaining the correct airflow over the engine’s cooling fins, ensuring that the engine operates within safe temperature ranges.

Integration with the Fan Drive Idler Assembly

Within the fan drive idler assembly, the 3092159 Idler Lever assists in modulating the fan’s speed in response to the engine’s temperature. This modulation is achieved by altering the position of the idler pulley, which changes the effective diameter of the pulley and thus the speed of the fan. This dynamic adjustment helps in optimizing the engine’s cooling efficiency under varying operating conditions.

Functionality in the Idler Pulley System

The idler pulley system relies on the 3092159 Idler Lever to maintain the correct alignment and tension of the drive belt. This ensures that the pulley can effectively change the direction of the belt’s movement, allowing for efficient power transmission to the fan. The lever’s ability to adjust the pulley’s position is key to the system’s overall performance and durability.

Conclusion

In summary, the 3092159 Idler Lever is a pivotal component in ensuring the seamless operation of the drive, fan, and idler systems within an engine. Its role in maintaining belt tension, adjusting fan speed, and ensuring proper alignment is essential for the engine’s cooling efficiency and overall performance.

-

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

A Field Guide to Automotive Technology, Ed Sobey, Chicago Review Press, 2009

↩ -

Fundamentals of Integrated Vehicle Realization, Mohamed ElSayed PE, SAE International, 2017

↩ -

Advanced Automotive Electricity and Electronics, Michael Klyde and Kirk VanGelder, Jones Bartlett Learning, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.