This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3060465 Idler Lever is a component designed for use in commercial trucks, specifically within the clutch system. Its purpose is to facilitate the smooth operation of the clutch by aiding in the engagement and disengagement of gears. This part ensures that gear shifts are performed with minimal resistance and maximum efficiency, contributing to the overall performance and durability of the truck’s transmission system.

Basic Concepts of Idler Levers

An idler lever is a mechanical component that serves as a linkage within a truck’s clutch system. It operates by transferring motion from the clutch pedal to the clutch release mechanism, allowing for the smooth and precise control of gear changes. The idler lever’s function is vital for the synchronization of the clutch system, ensuring that the clutch disengages and engages at the correct moments during shifting. This synchronization is key to preventing wear on the clutch and transmission components, as well as enhancing the driving experience by providing smooth and reliable gear changes 1.

Purpose of the Cummins 3060465 Idler Lever

The Cummins 3060465 Idler Lever is specifically designed to enhance the operation of the clutch system in commercial trucks. It plays a role in the precise movement of the clutch fork, which is responsible for engaging and disengaging the clutch. By providing a stable and consistent linkage between the clutch pedal and the clutch fork, this Cummins part aids in achieving smooth gear shifts. Its design and placement within the clutch system contribute to the efficient transfer of force, reducing the effort required by the driver to change gears and minimizing the risk of clutch slippage or damage 2.

Key Features

The Cummins 3060465 Idler Lever is characterized by its robust design and the use of high-quality materials to ensure durability and performance. It is crafted from materials that resist wear and corrosion, enhancing its longevity in the demanding environment of a commercial truck’s clutch system. The lever’s design includes features that allow for precise adjustment, ensuring optimal performance and compatibility with the truck’s clutch system. Additionally, its construction is aimed at minimizing maintenance requirements while maximizing reliability 3.

Benefits of Using the Cummins 3060465 Idler Lever

Incorporating the Cummins 3060465 Idler Lever into a truck’s clutch system offers several advantages. It contributes to improved clutch performance by ensuring smooth and reliable gear shifts. This enhancement not only improves the driving experience but also reduces wear on other components of the clutch and transmission system. Furthermore, the lever’s design and materials contribute to enhanced driver comfort and control, as gear changes become more effortless and precise. The overall result is a more efficient and durable clutch system, capable of withstanding the rigors of commercial truck operation 4.

Installation and Integration

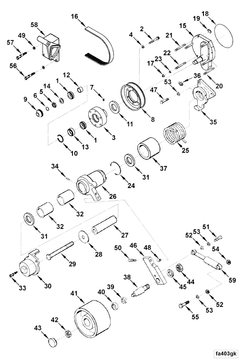

Proper installation of the Cummins 3060465 Idler Lever is crucial for its effective operation within the truck’s clutch system. The process involves ensuring that the lever is correctly aligned and securely fastened to prevent any movement that could affect its performance. Tools required for installation may include wrenches and screwdrivers, depending on the specific model of the truck. It is important to follow the manufacturer’s guidelines for installation to ensure that the lever is integrated into the clutch system correctly, allowing for optimal performance and durability.

Troubleshooting Common Issues

Common issues associated with idler levers can include difficulty in gear shifting, unusual noises during operation, or a feeling of resistance when changing gears. These problems may arise from improper installation, wear and tear, or misalignment of the lever. Addressing these issues often involves inspecting the lever for signs of damage or wear, ensuring it is correctly aligned, and making any necessary adjustments to its position. In some cases, lubrication of moving parts may be required to resolve issues related to resistance or noise.

Maintenance Tips

Regular maintenance of the Cummins 3060465 Idler Lever is key to ensuring its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, ensuring that all connections are secure, and that the lever operates smoothly within its range of motion. Lubrication of moving parts may be necessary to reduce friction and prevent wear. Additionally, keeping the lever clean and free from debris can help maintain its efficiency and reliability. Following these maintenance practices can help prevent common issues and ensure that the idler lever continues to perform its role effectively within the clutch system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong presence in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes a variety of components designed to enhance the performance, efficiency, and reliability of commercial vehicles. Cummins’ reputation in the industry is built on its dedication to advancing technology and providing solutions that meet the evolving needs of its customers.

Idler Lever Part 3060465 in Cummins Engines

The Idler Lever part number 3060465, manufactured by Cummins, is an integral component in several Cummins engine models. This part plays a role in the engine’s operation by managing the tension of the timing belt or chain, ensuring smooth and efficient engine performance.

K19 Engines

In the K19 engine series, the Idler Lever 3060465 is designed to maintain the correct tension of the timing belt. This ensures that the camshaft and crankshaft are synchronized, which is vital for the engine’s overall performance and longevity. The K19 engines benefit from this part’s precision, as it helps in reducing wear and tear on other engine components.

QSK19 Engines

For the QSK19 engines, the Idler Lever 3060465 is equally important. These engines, known for their robustness and reliability, depend on this part to keep the timing mechanism in check. The QSK19 series is often used in heavy-duty applications, and the Idler Lever’s role in maintaining timing belt tension is critical for the engine’s durability and efficiency.

CM500 Engines

The CM500 engines also utilize the Idler Lever 3060465. In these engines, the part ensures that the timing chain remains properly tensioned, which is essential for the smooth operation of the engine’s valves and pistons. The CM500 engines are typically found in industrial and marine applications, where reliability and performance are paramount.

Grouping of Engines

The Idler Lever 3060465 is a versatile component that fits seamlessly into the K19, QSK19, and CM500 engine families. Its design and functionality are tailored to meet the specific needs of these engines, ensuring optimal performance across various applications. The commonality in the use of this part across these engine groups highlights its importance in maintaining the integrity of the timing mechanism.

Role of Part 3060465 Idler Lever in Engine Systems

The 3060465 Idler Lever is an integral component in the efficient operation of various engine systems, particularly in the coordination between the drive mechanism and the fan.

In the context of the drive system, the idler lever plays a role in maintaining tension within the belt-driven components. It ensures that the drive belt remains properly aligned and under the correct amount of tension, which is essential for the smooth transfer of power from the engine to other mechanical parts. This tensioning function helps in reducing slippage and wear, thereby enhancing the longevity and performance of the drive system.

When it comes to the fan system, the 3060465 Idler Lever assists in the precise control of the fan’s operation. By adjusting the position and tension of the fan belt, the idler lever helps in optimizing the fan’s speed and efficiency. This is particularly important in managing the engine’s cooling system, as the fan is responsible for dissipating heat by drawing air through the radiator. Proper functioning of the idler lever ensures that the fan operates at the optimal speed, providing adequate cooling without unnecessary strain on the engine.

Overall, the 3060465 Idler Lever is a key component that contributes to the harmonious operation of both the drive and fan systems within an engine, ensuring that each component performs its function effectively and efficiently.

Conclusion

The Cummins 3060465 Idler Lever is a critical component in the operation of commercial truck clutch systems and various engine models. Its role in ensuring smooth gear shifts, maintaining timing belt or chain tension, and optimizing the operation of drive and fan systems underscores its importance in enhancing vehicle performance, efficiency, and reliability. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this part, contributing to the overall durability and effectiveness of the vehicle’s powertrain.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018

↩ -

Vehicle Noise, Vibration and Sound Quality, Gang Sheng, SAE International, 2012

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

The Dynamic Behavior of a Diesel Engine, S. A. Miedema, Z. Lu, Published by Drir S. A. Miedema, 2010

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.