5562829

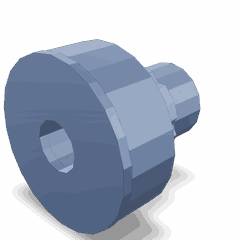

Vibration Isolator

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5562829 Vibration Isolator is a component designed to mitigate the transmission of vibrations from the engine to the truck’s frame and other components. In the context of commercial truck operations, this part plays a significant role in enhancing the overall performance and longevity of the vehicle 1.

Basic Concepts of Vibration Isolators

Vibration isolators are devices used in mechanical systems to reduce the transmission of vibrations from a source to its surroundings. They function by absorbing or dampening the vibrational energy, thereby protecting the integrity and performance of connected equipment. The principles of vibration isolation involve the use of materials and designs that can absorb, reflect, or redirect vibrational energy. This is particularly important in maintaining the structural integrity and operational efficiency of machinery 2.

Purpose of the Cummins 5562829 Vibration Isolator

The Cummins 5562829 Vibration Isolator is specifically designed to reduce the vibrations transmitted from the engine to the truck’s frame and other components. By doing so, it helps in maintaining the structural integrity of the truck, ensuring smoother operation, and potentially extending the lifespan of various components by minimizing wear and tear caused by excessive vibrations 3.

Key Features

The Cummins 5562829 Vibration Isolator features a design that incorporates high-quality materials to enhance its performance and durability. Its construction includes robust components that are engineered to withstand the rigors of commercial truck operations. Unique characteristics of this isolator may include specific damping properties and a design that ensures optimal vibration reduction.

Benefits of Using the Cummins 5562829 Vibration Isolator

Incorporating the Cummins 5562829 Vibration Isolator into truck designs offers several advantages. These include improved ride comfort for the driver and passengers, reduced wear and tear on truck components, enhanced engine performance, and the potential for increases in fuel efficiency. By effectively managing vibrations, this isolator contributes to the overall reliability and efficiency of the truck.

Installation Considerations

For the installation of the Cummins 5562829 Vibration Isolator, it is important to follow guidelines and best practices to ensure optimal performance. This may involve adhering to specific torque specifications, ensuring proper alignment, and completing any preparatory steps necessary for installation. Careful attention to these details helps in achieving the desired vibration isolation performance.

Troubleshooting Common Issues

Common problems associated with vibration isolators can include excessive vibration, unusual noises, or performance degradation. Troubleshooting these issues may involve diagnosing the source of the problem, checking for proper installation, and ensuring that the isolator is functioning as intended. Addressing these issues promptly can help in maintaining the effectiveness of the vibration isolation system.

Maintenance Tips

Regular maintenance of the Cummins 5562829 Vibration Isolator is recommended to ensure longevity and consistent performance. This may include periodic inspections, cleaning procedures to remove any debris or contaminants, and monitoring for signs of wear or damage. Knowing when to consider replacement is also important in maintaining the effectiveness of the vibration isolation system.

Cummins Corporation Overview

Cummins Inc. is a well-established manufacturer with a history of producing high-quality engines and components for the commercial truck industry. The company’s product range includes a variety of engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of commercial vehicle operations. Cummins is recognized for its commitment to quality, innovation, and customer satisfaction in the industry.

Cummins Engine Compatibility with Vibration Isolator Part 5562829

The Cummins Vibration Isolator part 5562829 is designed to be compatible with a variety of Cummins engines, ensuring optimal performance and reduced vibration across multiple engine models. Here is an overview of the engines that this part fits:

B6.7 Series Engines

- B6.7 CM2670 B153B

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

F3.8 Series Engines

- F3.8 CM2350 F128C

- QSF3.8 CM2350 F107

G12/X12 Series Engines

- QSG12/X12 CM2350 G110

L9 Series Engines

- QSL9 CM2350 L102

- QSL9 CM850 (CM2850)

X12 Series Engines

- X12 CM2670 X121B

This vibration isolator is engineered to fit seamlessly with these engines, providing a reliable solution for vibration management. It is essential to verify the compatibility of this part with your specific engine model to ensure proper installation and performance.

Role of Part 5562829 Vibration Isolator in Engine Systems

When integrating part 5562829 Vibration Isolator into engine systems, it is essential to understand its interaction with various components to ensure optimal performance and longevity of the engine.

Interaction with the Engine Control Module (ECM)

The Vibration Isolator, part 5562829, plays a significant role in maintaining the stability and efficiency of the Engine Control Module (ECM). By reducing mechanical vibrations transmitted to the ECM, it helps in preserving the integrity of sensitive electronic components within the module. This is particularly important in high-vibration environments where consistent and accurate data processing by the ECM is necessary for precise fuel injection, ignition timing, and other critical engine management functions.

Benefits for Engine Mounts

Incorporating the Vibration Isolator into the engine mount system enhances the overall effectiveness of the mounts. It mitigates the transfer of engine vibrations to the vehicle’s chassis, leading to improved ride comfort and reduced wear on mounting components. This results in a more stable engine operation, which is beneficial for both performance and durability.

Impact on Fuel Injectors

Fuel injectors are precision devices that can be adversely affected by excessive vibrations. The Vibration Isolator helps in minimizing these vibrations, ensuring that fuel injectors operate within their specified tolerances. This leads to more consistent fuel delivery, better combustion efficiency, and ultimately, enhanced engine performance.

Contribution to Exhaust System Components

The exhaust system, including components like the catalytic converter and muffler, can experience increased stress from engine vibrations. By attenuating these vibrations, part 5562829 contributes to the longevity and efficiency of the exhaust system. This is particularly important for maintaining emissions standards and ensuring the exhaust system operates smoothly over the vehicle’s lifespan.

Enhancement of Sensor Performance

Various sensors, such as the Mass Air Flow (MAF) sensor and Oxygen (O2) sensor, are integral to the engine’s operation. Vibrations can interfere with the accuracy of these sensors. The Vibration Isolator helps in maintaining a stable environment for these sensors, ensuring they provide reliable data to the ECM for optimal engine management.

Support for Ancillary Components

Ancillary components like the alternator, power steering pump, and air conditioning compressor are also susceptible to vibrations. The Vibration Isolator aids in reducing the impact of engine vibrations on these components, leading to improved reliability and efficiency. This is especially important in ensuring that these systems operate smoothly and do not contribute to additional wear on the engine.

Conclusion

In summary, the Cummins 5562829 Vibration Isolator is a valuable component in enhancing the performance and durability of various engine systems by effectively managing and reducing unwanted vibrations. Its integration into engine systems contributes to improved ride comfort, reduced wear on components, enhanced engine performance, and increased fuel efficiency. Regular maintenance and proper installation are crucial to ensuring the longevity and effectiveness of this part.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.