This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4012910 Swirl Insert is a component designed to enhance the performance of heavy-duty diesel engines. Its purpose is to improve the efficiency of the combustion process within the engine, which in turn contributes to better overall engine operation. The significance of this Cummins part lies in its ability to optimize fuel consumption, reduce emissions, and enhance engine performance, making it a valuable component in the maintenance and operation of heavy-duty trucks 1.

Basic Concepts of Swirl Inserts

Swirl inserts are components installed in the intake ports of diesel engines. They function by creating a swirling motion in the air entering the combustion chamber, which enhances the mixing of air and fuel. This improved mixing leads to more efficient combustion, which can result in better fuel economy, lower emissions, and increased engine power. The role of swirl inserts in the engine is to facilitate a more complete and efficient burn of the fuel-air mixture 2.

Purpose of the 4012910 Swirl Insert

The 4012910 Swirl Insert plays a role in the operation of a truck by optimizing the combustion process. It contributes to improved fuel efficiency by ensuring that the fuel is burned more completely. This can lead to reduced fuel consumption over time. Additionally, the insert helps in lowering emissions by promoting cleaner combustion. The enhanced combustion efficiency also supports better engine performance, allowing the engine to operate more smoothly and with greater power. Furthermore, by improving combustion, the insert can contribute to the longevity of engine components by reducing the stress and wear that result from inefficient combustion 3.

Key Features

The primary features of the 4012910 Swirl Insert include its specific design, which is tailored to create the optimal swirl effect in the intake air. The materials used in its construction are chosen for their durability and ability to withstand the high temperatures and pressures within the engine. Unique characteristics of this swirl insert may include its precise engineering to fit specific engine models, ensuring compatibility and effectiveness.

Benefits of Using the 4012910 Swirl Insert

The advantages provided by the 4012910 Swirl Insert include improved fuel economy due to more efficient combustion. This can result in cost savings over time for operators of heavy-duty trucks. Reduced emissions are another benefit, as the insert helps to minimize the environmental impact of the vehicle. Enhanced engine performance is also a key advantage, with the insert contributing to smoother operation and increased power. Additionally, the longevity of engine components may be extended, as the insert helps to reduce the wear and tear associated with inefficient combustion.

Installation Process

Proper installation of the 4012910 Swirl Insert involves several steps to ensure optimal performance. The process typically requires specific tools and equipment to remove the old insert, clean the intake port, and install the new insert. Best practices include ensuring a proper fit and seal to prevent air leaks, which can negatively impact engine performance. Detailed instructions should be followed to achieve the best results.

Troubleshooting and Maintenance

Common issues that may arise with the 4012910 Swirl Insert include improper installation, which can lead to reduced efficiency or engine performance issues. Diagnostic procedures may involve checking for air leaks, assessing combustion efficiency, and monitoring engine performance metrics. Maintenance tips to prolong the lifespan of the insert include regular inspections for wear or damage, ensuring it remains clean and free from debris, and following manufacturer recommendations for service intervals.

Compatibility and Applications

The 4012910 Swirl Insert is designed for specific types of engines and vehicles, with compatibility information available to ensure it is used in the appropriate applications. This includes details on the engine models and series it is intended for, helping to ensure optimal performance and compatibility.

Performance Data and Testing

Overview of performance data and testing results for the 4012910 Swirl Insert includes metrics such as fuel efficiency gains, emission reductions, and durability under various operating conditions. This data provides insight into the insert’s effectiveness and can help in making informed decisions about its use in heavy-duty diesel engines.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories through a network of more than 600 company-owned and independent distributor facilities and more than 7,200 dealer locations. The company’s product range includes engines, filtration, emissions solutions, and related components, all designed to meet the demanding requirements of heavy-duty applications.

Role of Part 4012910 Swirl Insert in Engine Systems

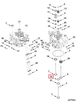

The Swirl Insert, identified by part number 4012910, is an integral component within various engine systems, contributing to the optimization of combustion efficiency and overall engine performance.

In the Cylinder Head and Cylinder Assembly Head, the Swirl Insert enhances the swirling motion of the air-fuel mixture. This improved turbulence leads to a more uniform distribution of the mixture, facilitating a more complete and efficient combustion process. The result is an engine that operates with greater efficiency and reduced emissions.

When integrated into a Cylinder Head Kit, the Swirl Insert works in conjunction with other components to fine-tune the combustion chamber’s dynamics. This synergy ensures that the engine not only meets performance expectations but also adheres to stringent emission standards.

In the context of a Pressure Test on the Cylinder Head, the Swirl Insert’s role becomes even more apparent. The insert’s design allows for precise control over the airflow within the combustion chamber, which is essential for maintaining consistent pressure levels during the test. This consistency is vital for accurate diagnostic results and ensures that the cylinder head is functioning within specified parameters.

The Camshaft, although not directly interacting with the Swirl Insert, benefits from the insert’s enhanced combustion efficiency. A more efficient burn means that the camshaft can operate with less stress, potentially leading to extended component lifespan and improved engine reliability.

The Connecting Rod and Piston assembly also sees indirect benefits from the Swirl Insert. With more efficient combustion, the force exerted on the piston during the power stroke is optimized. This results in smoother operation and reduced wear on the connecting rod, contributing to the overall durability of the engine.

Conclusion

In summary, the Swirl Insert (part 4012910) plays a significant role in enhancing the functionality of various engine components. Its contribution to improved combustion efficiency has a cascading effect on the performance and longevity of the engine system as a whole.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Gus Wright, Fundamentals of Medium-Heavy Duty Diesel Engines, Jones & Bartlett Learning, 2015.

↩ -

Andrew Norman, Diesel Technology Fundamentals Service Repair Eighth Edition, The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.