This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

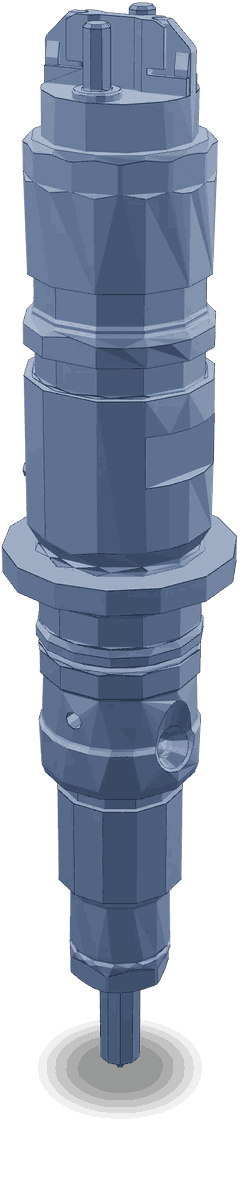

The Cummins 5364204 Injector is a critical component for heavy-duty trucks, ensuring efficient engine operation by delivering fuel precisely into the combustion chamber. This part is integral to Cummins Inc.’s range of high-performance components designed to enhance engine reliability and efficiency.

Basic Concepts of Fuel Injectors

Fuel injectors atomize fuel under high pressure to create a fine mist that mixes with air for combustion. The efficiency of this process is vital for engine performance, fuel economy, and emissions control 1. Modern injectors, such as the Cummins 5364204, are electronically controlled for precise fuel delivery, which is essential for maintaining engine efficiency and power output 2.

Purpose of the Cummins 5364204 Injector

This Cummins part is designed to optimize fuel delivery in heavy-duty truck engines. By ensuring a consistent and precise fuel spray, it enhances combustion efficiency, leading to improved engine performance and fuel efficiency. Its role in the combustion process is fundamental, optimizing the engine’s power output and efficiency.

Key Features

The Cummins 5364204 Injector features advanced materials and technology to withstand high pressures and temperatures within a diesel engine. Its precise engineering allows for accurate fuel delivery, and it may include electronic control for fine-tuning injection parameters, contributing to its overall effectiveness.

Benefits of Using the Cummins 5364204 Injector

Utilizing this part in heavy-duty trucks offers advantages such as improved fuel efficiency, enhanced engine performance, and increased reliability under demanding conditions. Its precise fuel delivery contributes to smoother operation and potentially higher power output.

Installation and Integration

Proper installation of the Cummins 5364204 Injector is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the engine and maintain the integrity of the fuel system. Following recommended procedures for integration is important to ensure correct alignment, secure fastening, and proper sealing to prevent leaks.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 5364204 Injector is essential for ensuring its continued performance. This includes periodic inspection for wear or damage, cleaning to remove deposits, and checking for proper function. Troubleshooting tips involve verifying electrical connections, ensuring correct voltage, and checking for fuel leaks to maintain the injector’s efficiency and longevity.

Performance Enhancements

The Cummins 5364204 Injector contributes to overall truck performance by providing precise fuel delivery, leading to more complete combustion, increased power output, and improved fuel economy. Efficient combustion also results in lower emissions, contributing to a cleaner operation of the vehicle.

Compatibility and Upgrades

This injector is designed for compatibility with various truck models and engine types. Upgrades, such as injectors with higher flow rates or more advanced electronic control systems, can offer additional improvements in engine performance, fuel efficiency, and emissions reduction.

Cummins Corporation Overview

Cummins Inc. is a global leader in power solutions, including engines, filtration, and emissions solutions. With a history of over a century, Cummins is known for quality, reliability, and innovation in the automotive and heavy-duty truck industries. The company’s extensive product range and commitment to excellence make it a preferred choice for professionals seeking high-performance and durable components for their vehicles.

Role of 5364204 Injector in Engine Systems

The 5364204 injector is a vital component in the fuel delivery system of an engine. Its primary function is to atomize fuel into the combustion chamber at precise intervals and in the correct quantity, ensuring an optimal fuel-air mixture for efficient combustion.

Interaction with Fuel Rail

The injector is mounted on the fuel rail, which distributes pressurized fuel to each injector. The fuel rail maintains consistent pressure, allowing the injector to deliver fuel accurately. The injector’s solenoid, controlled by the engine control unit (ECU), opens and closes to release fuel into the intake port or directly into the combustion chamber.

Coordination with ECU

The ECU plays a significant role in the operation of the injector. It monitors various engine parameters such as engine speed, load, and temperature. Based on this data, the ECU sends signals to the injector to open and close at specific times, ensuring the correct amount of fuel is delivered for each combustion cycle.

Relationship with Intake Manifold

Once the fuel is atomized by the injector, it mixes with air in the intake manifold before entering the combustion chamber. The intake manifold distributes the air-fuel mixture evenly to each cylinder. The injector’s precise fuel delivery helps maintain a consistent air-fuel ratio, which is essential for engine performance and emissions control.

Impact on Combustion Chamber

The atomized fuel from the injector enters the combustion chamber, where it mixes with air and ignites. The injector’s ability to deliver fuel in a fine mist ensures complete combustion, maximizing power output and minimizing unburnt fuel. This efficient combustion is key to the engine’s overall performance and fuel efficiency.

Influence on Exhaust System

The quality of combustion directly affects the exhaust system. Efficient fuel delivery by the injector results in cleaner combustion, reducing the amount of unburnt hydrocarbons and other pollutants entering the exhaust system. This not only improves engine performance but also helps in meeting emissions standards 3.

Synergy with Oxygen Sensor

The oxygen sensor monitors the amount of oxygen in the exhaust gases, providing feedback to the ECU. This data allows the ECU to adjust the fuel delivery by the injector, ensuring the air-fuel mixture remains optimal under varying driving conditions. The injector’s precise fuel delivery is essential for the oxygen sensor to function effectively.

Conclusion

In summary, the Cummins 5364204 Injector plays a significant role in the fuel delivery system, working in harmony with the fuel rail, ECU, intake manifold, combustion chamber, exhaust system, and oxygen sensor to ensure efficient and clean engine operation.

-

Huang, M. (2002). Vehicle Crash Dynamics. CRC Press.

↩ -

Reif, K. (Ed.). (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Boger, T., & Cutler, W. (2018). Reducing Particulate Emissions in Gasoline Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.