This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

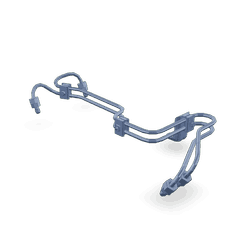

The Cummins Injector Fuel Supply Tube, part number 5343214, is a critical component in the fuel delivery system of heavy-duty diesel engines. This part ensures a steady and precise flow of fuel to the injectors, which is essential for maintaining optimal engine performance and efficiency.

Function and Operation

The Injector Fuel Supply Tube operates as a conduit within the fuel injection system. Its primary role is to deliver fuel from the fuel rail to the injectors with precision. This ensures that the fuel is metered accurately, which is crucial for maintaining consistent engine performance. The tube is engineered to withstand the high pressures and temperatures present in the fuel system, ensuring reliable operation under various operating conditions 1.

Key Features

This Cummins part is constructed from high-quality materials that enhance its durability and performance. Its design includes features that ensure a secure fit within the fuel system, reducing the likelihood of leaks and ensuring consistent fuel delivery. The tube is also designed to resist corrosion, which is particularly important in environments where the fuel may contain contaminants. These features contribute to the overall reliability and longevity of the component 2.

Benefits

The use of the Injector Fuel Supply Tube offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered to the injectors with minimal loss. This precise fuel metering also enhances engine performance, allowing for more consistent power output. Additionally, the tube’s robust construction and resistance to corrosion make it reliable in demanding operating conditions, reducing the need for frequent replacements and maintenance 3.

Installation and Maintenance

Proper installation of the Injector Fuel Supply Tube is crucial for ensuring its optimal performance. This involves adhering to specified torque values and alignment procedures to secure the tube within the fuel system. Regular maintenance, including inspections for leaks and corrosion, is recommended to ensure the longevity and performance of the component. Following these guidelines helps maintain the integrity of the fuel system and ensures consistent engine operation.

Troubleshooting Common Issues

Common issues associated with the Injector Fuel Supply Tube include fuel leaks, clogged passages, and corrosion. To address these problems, a systematic approach to troubleshooting is recommended. This involves inspecting the tube for signs of wear or damage, cleaning any clogged passages, and replacing the tube if corrosion is detected. Proper diagnosis and resolution of these issues help maintain the efficiency and reliability of the fuel system.

Compatibility and Application

The Injector Fuel Supply Tube is designed to be compatible with various Cummins engine models and is suitable for use in heavy-duty truck applications. Its design ensures it can operate effectively in different environments and with various fuel types, making it a versatile component for a wide range of applications.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability in the diesel engine and power generation industries. The company’s product portfolio includes a wide range of components designed to meet the demands of various applications, underscoring its dedication to excellence in manufacturing automotive components.

Conclusion

The Injector Fuel Supply Tube, part number 5343214, plays a vital role in the fuel delivery system of heavy-duty diesel engines. Its precise design and robust construction ensure reliable and efficient fuel delivery, contributing to optimal engine performance and longevity. Proper installation, maintenance, and troubleshooting are essential to maximize the benefits of this component.

-

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩ -

Hu, Haoran, Rudy Smaling, and Simon Baseley. Heavy-Duty Wheeled Vehicles. SAE International, 2014.

↩ -

Smil, Vaclav. The History and Impact of Diesel Engines and Gas Turbines. The MIT Press, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.