This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

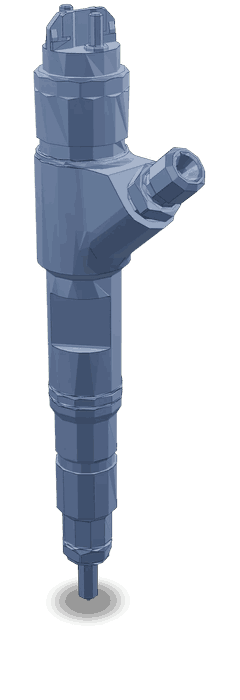

The Cummins 5337000 Injector is a component designed for use in commercial trucks, playing a significant role in the efficient operation of these vehicles. This injector is part of Cummins Inc.’s lineup of diesel engine components, known for their reliability and performance. The injector is integral to the fuel delivery system, ensuring that diesel engines operate smoothly and efficiently.

Basic Concepts of Fuel Injectors

Fuel injectors are devices that deliver fuel into an engine’s combustion chamber. They operate by atomizing fuel into a fine mist, which mixes with air for combustion. This process is vital for the engine’s performance, as it directly affects the combustion efficiency and, consequently, the engine’s power output and fuel economy. Fuel injectors must be precisely calibrated to deliver the correct amount of fuel at the right time, ensuring optimal engine performance and emissions control 1.

Purpose of the Cummins 5337000 Injector

The Cummins 5337000 Injector serves a specific function within the fuel delivery system of a truck. It is responsible for injecting diesel fuel into the engine’s cylinders at high pressure and precise timing. This injection process is crucial for achieving efficient combustion, which in turn affects the engine’s power output, fuel efficiency, and emissions levels. The injector’s role in fuel delivery and combustion efficiency is fundamental to the overall performance of the truck’s engine.

Key Features

The Cummins 5337000 Injector is characterized by several key features that enhance its performance. Its design incorporates advanced technology to ensure precise fuel delivery. The materials used in its construction are selected for durability and resistance to the high pressures and temperatures within a diesel engine. These features contribute to the injector’s reliability and efficiency in demanding commercial truck applications.

Benefits

The use of the Cummins 5337000 Injector offers several advantages. It contributes to improved fuel efficiency by ensuring that fuel is delivered in an optimal manner for combustion. This results in enhanced engine performance, with increased power output and torque. Additionally, the precise fuel delivery helps in reducing emissions, making the engine more environmentally friendly and compliant with emissions regulations.

Installation and Compatibility

Proper installation of the Cummins 5337000 Injector is crucial for its effective operation. It is designed to be compatible with specific Cummins engine models, ensuring that it fits and functions correctly within the engine’s fuel system. Following the manufacturer’s guidelines for installation is important to maintain the injector’s performance and the engine’s efficiency.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 5337000 Injector is necessary to ensure its continued optimal performance. This includes periodic inspection, cleaning, and, when necessary, replacement of the injector. Common issues such as poor fuel atomization or injector clogging can often be addressed through proper maintenance practices. Troubleshooting these problems early can prevent more significant engine performance issues.

Performance Enhancements

The Cummins 5337000 Injector contributes to the overall engine performance by enhancing power output, torque, and fuel economy. Its precise fuel delivery system ensures that the engine operates at peak efficiency. Additionally, there may be available upgrades or modifications that can further enhance the injector’s performance, offering even greater benefits in terms of engine power and fuel efficiency.

Environmental Impact

The use of the Cummins 5337000 Injector has a positive environmental impact. By ensuring efficient fuel combustion, it helps in reducing emissions from the engine. This not only contributes to a cleaner environment but also aids in meeting regulatory standards for emissions control. The injector’s role in improving fuel efficiency further reduces the overall environmental footprint of commercial trucks.

Cummins Corporation

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation in the diesel engine and power generation industries, Cummins is committed to providing reliable and efficient products. The company’s extensive product offerings and focus on technological advancement make it a key player in the commercial vehicle and power generation markets.

Cummins Injector 5337000 Compatibility with Various Engines

The Cummins Injector part number 5337000 is designed to fit seamlessly with several engine models, ensuring optimal performance and reliability. This injector is compatible with the following engines:

F3.8 CM2350 F109 and ISF3.8 CM2350 F109

The injector 5337000 is engineered to integrate perfectly with the F3.8 CM2350 F109 and ISF3.8 CM2350 F109 engines. These engines benefit from the precise fuel delivery provided by this injector, enhancing overall engine efficiency and power output.

F3.8 CM2620 F137B and F120B

Similarly, the injector 5337000 is also compatible with the F3.8 CM2620 F137B and F120B engines. This compatibility ensures that these engines receive the necessary fuel in a controlled manner, contributing to their smooth operation and longevity.

By using the Cummins Injector 5337000, these engines can maintain their performance standards, providing reliable power across various applications.

Role of Part 5337000 Injector in Engine Systems

The part 5337000 injector is an integral component in the orchestration of engine systems, ensuring optimal performance and efficiency. Its primary function is to deliver a precise amount of fuel into the combustion chamber at the exact moment required for efficient burning. This timing and precision are essential for the overall performance of the engine.

When the injector is activated, it sprays fuel into the cylinder where the piston, driven by the connecting rod, is in motion. The fuel mixes with the air already present in the cylinder, creating a combustible mixture. The injector’s role is to ensure that this mixture is as homogeneous as possible, which is vital for complete combustion and, consequently, for maximizing engine efficiency and power output.

The injector works in concert with the engine’s head, which houses the intake and exhaust valves. The timing of the injector’s fuel delivery is synchronized with the opening and closing of these valves to ensure that the fuel is introduced into the cylinder at the optimal moment. This coordination is essential for maintaining the engine’s performance and reducing emissions.

The injector’s performance is also influenced by the condition of other parts within the engine system. For instance, a well-maintained cylinder will provide a clean surface for the fuel-air mixture to ignite, while a worn cylinder may lead to incomplete combustion and reduced engine performance. Similarly, the injector must work in harmony with the piston and connecting rod to ensure that the fuel is delivered at the precise moment when the piston is at the top of its compression stroke.

In summary, the part 5337000 injector is a key player in the engine’s complex system, interacting with the head, cylinder, piston, and connecting rod to deliver fuel at the right time and in the right quantity. This ensures that the engine operates efficiently, with optimal performance and minimal emissions.

Conclusion

The Cummins 5337000 Injector is a critical component in the fuel delivery system of commercial trucks, designed to enhance engine performance, fuel efficiency, and reduce emissions. Its precise fuel delivery, compatibility with specific engine models, and the need for regular maintenance ensure that it continues to operate at peak efficiency. The injector’s role in the engine system is integral, working in harmony with other components to deliver optimal performance and environmental benefits.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.