This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

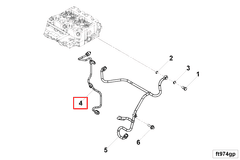

The Cummins 5316116 Injector Fuel Supply Tube is a component designed for use in commercial trucks. It serves a significant role in the fuel system by facilitating the delivery of fuel to the injectors. This part is integral to ensuring that the engine operates efficiently and reliably.

Basic Concepts

Injector Fuel Supply Tubes are vital components within the fuel system of diesel engines. Their primary function is to transport fuel from the fuel tank to the injectors under precise pressure and flow conditions. This ensures that the fuel is delivered in the correct quantity and at the right time, which is crucial for optimal engine performance 1. The tubes must be capable of withstanding high pressures and temperatures, as well as resisting corrosion and wear to maintain the integrity of the fuel system.

Purpose and Function

The Cummins 5316116 Injector Fuel Supply Tube plays a role in the operation of a truck by delivering fuel to the injectors. It is designed to maintain a consistent fuel supply, which is necessary for the injectors to atomize the fuel properly. This atomization is critical for efficient combustion within the engine cylinders 2. Additionally, the tube helps in maintaining the overall integrity of the fuel system by ensuring that fuel is delivered without leaks or interruptions.

Key Features

The Cummins 5316116 Injector Fuel Supply Tube is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel or other durable materials that can withstand the high pressures and temperatures within the fuel system. The tube is also designed to be resistant to corrosion, which is important for longevity and reliability in commercial truck applications 3. Additionally, the tube may feature specific connections or fittings that ensure a secure and leak-free installation.

Benefits

Using the Cummins 5316116 Injector Fuel Supply Tube can lead to improved fuel delivery efficiency. This is due to its precise design and the materials used, which allow for consistent fuel flow under varying engine conditions. Enhanced engine performance can be observed as a result of the efficient fuel delivery, leading to better overall truck operation. Furthermore, the durability and reliability of the tube contribute to reduced maintenance needs and increased uptime for commercial trucks 4.

Installation and Compatibility

Proper installation of the Cummins 5316116 Injector Fuel Supply Tube is important to ensure it functions correctly within the fuel system. Installation procedures should follow manufacturer guidelines to avoid damage to the tube or the fuel system. Compatibility with different truck models and engine configurations should be considered to ensure the tube fits correctly and operates efficiently within the specific application.

Maintenance and Troubleshooting

Regular maintenance of the Cummins 5316116 Injector Fuel Supply Tube is important to ensure its continued performance and longevity. This includes checking for signs of wear, corrosion, or leaks, and performing any necessary cleaning or repairs. Troubleshooting common issues, such as fuel delivery problems or leaks, may involve inspecting the tube for damage, ensuring connections are secure, and verifying that the tube is compatible with the fuel system components. Recommended maintenance intervals should be followed to prevent issues and ensure optimal performance.

Cummins Overview

Cummins Inc. is a well-established manufacturer within the commercial truck industry, known for its wide range of diesel engines and related components. The company has a history of innovation and quality, offering products that are designed to meet the demanding requirements of commercial trucking. Cummins’ reputation for reliability and performance makes its components, including the 5316116 Injector Fuel Supply Tube, a popular choice among truck operators and maintenance professionals.

Cummins Injector Fuel Supply Tube (Part 5316116) Compatibility

The Cummins Injector Fuel Supply Tube, identified by part number 5316116, is a critical component in the fuel delivery system of various Cummins engines. This part ensures the efficient transfer of fuel from the fuel supply system to the injectors, maintaining optimal engine performance.

ISF3.8 CM2220 AN

The ISF3.8 CM2220 AN engine is one of the models that benefit from the precise engineering of the 5316116 Injector Fuel Supply Tube. This part is designed to withstand the high pressures and temperatures associated with diesel engines, ensuring durability and reliability over extended periods of use.

Application in Cummins Engines

The injector fuel supply tube is integral to the operation of Cummins engines, providing a secure and leak-free connection between the fuel supply system and the injectors. This ensures that the engine receives the correct amount of fuel at the right time, which is crucial for maintaining performance and efficiency.

The 5316116 part number is specifically engineered to fit seamlessly into the fuel systems of Cummins engines, ensuring compatibility and ease of installation. This compatibility extends across various Cummins engine models, making it a versatile component for maintenance and repair purposes.

Role of Part 5316116 Injector Fuel Supply Tube in Engine Systems

The Injector Fuel Supply Tube, identified by part number 5316116, is an essential component in the fuel delivery system of an engine. It is responsible for transporting fuel from the fuel rail to the individual fuel injectors. This part ensures a consistent and regulated flow of fuel, which is necessary for the precise operation of the injectors.

Integration with Fuel System Components

-

Fuel Rail: The Injector Fuel Supply Tube connects directly to the fuel rail, which is a pressurized manifold that distributes fuel to each injector. The tube ensures that fuel is delivered under the correct pressure to maintain efficient combustion.

-

Fuel Injectors: Each fuel injector is supplied with fuel via the Injector Fuel Supply Tube. The tube’s design allows for minimal pressure drop, ensuring that each injector receives an equal amount of fuel. This uniformity is vital for balanced engine performance and emissions control.

-

Fuel Pressure Regulator: The tube works in conjunction with the fuel pressure regulator to maintain the desired fuel pressure within the system. Consistent pressure is essential for the injectors to atomize fuel properly, leading to better fuel efficiency and reduced emissions.

-

Return Line: In systems with a return line, the Injector Fuel Supply Tube helps manage the flow of excess fuel back to the tank. This ensures that the fuel rail pressure remains stable, even under varying engine loads.

Interaction with Plumbing Components

-

Fuel Lines: The Injector Fuel Supply Tube is often connected to fuel lines that transport fuel from the tank to the engine. These lines must be compatible with the tube to ensure a leak-free connection and consistent fuel delivery.

-

Fittings and Connectors: Various fittings and connectors are used to secure the Injector Fuel Supply Tube to other components. These must be correctly installed to prevent fuel leaks and ensure the system operates under the designed pressure parameters.

-

Seals and Gaskets: Seals and gaskets are employed at connection points to maintain the integrity of the fuel system. The Injector Fuel Supply Tube relies on these components to prevent fuel from escaping, which could lead to performance issues or safety hazards.

Conclusion

In summary, the Injector Fuel Supply Tube (part 5316116) plays a significant role in the fuel delivery system by ensuring a consistent and regulated supply of fuel to the injectors. Its integration with other fuel system components and plumbing elements is essential for the overall efficiency and performance of the engine.

-

Reif, K. (2014). Diesel Engine Management Systems and Components. Springer.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.