This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

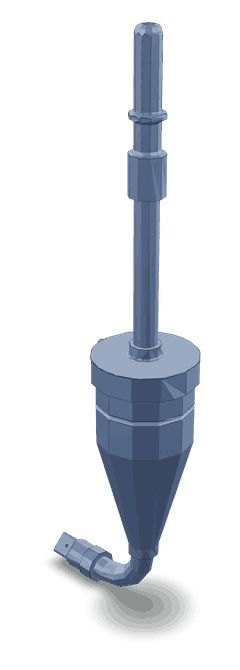

The Cummins 5307918 Dosing Injector is a critical component in commercial trucks, specifically within the Selective Catalytic Reduction (SCR) system. This part is designed to inject a precise amount of Diesel Exhaust Fluid (DEF) into the exhaust stream, which aids in reducing nitrogen oxide (NOx) emissions. The injector is significant in the operation of commercial trucks as it helps meet stringent emissions regulations while maintaining engine performance 1.

Basic Concepts of Dosing Injectors

Dosing injectors are essential devices in diesel engines, used to introduce DEF into the exhaust stream as part of the SCR system. This system is designed to convert NOx into nitrogen and water vapor, thereby reducing harmful emissions. The dosing injector controls the amount of DEF injected, ensuring optimal reduction of NOx emissions without adversely affecting engine performance 2.

Purpose of the Cummins 5307918 Dosing Injector

The Cummins 5307918 Dosing Injector is integral to the SCR system in commercial trucks. It functions by injecting DEF into the exhaust stream at specific intervals and quantities, determined by the engine’s Electronic Control Unit (ECU). This injection facilitates the chemical reaction that converts NOx into harmless nitrogen and water vapor, contributing to the truck’s emissions control system 3.

Key Features

The Cummins 5307918 Dosing Injector is characterized by several key features. Its design incorporates advanced materials to withstand the harsh conditions of the exhaust system. Technological advancements include precise control mechanisms that ensure accurate dosing of DEF, contributing to efficient emissions reduction. The injector is also engineered for durability and reliability, ensuring long-term performance in demanding commercial truck applications.

Benefits of Using the Cummins 5307918 Dosing Injector

Utilizing the Cummins 5307918 Dosing Injector offers several advantages. It contributes to improved emissions performance by effectively reducing NOx emissions. This injector also enhances engine efficiency by ensuring the SCR system operates within optimal parameters. Additionally, it aids in compliance with environmental regulations, helping truck operators meet emissions standards without compromising on engine performance.

Installation and Integration

Proper installation of the Cummins 5307918 Dosing Injector involves following manufacturer guidelines to ensure compatibility with the truck’s engine and exhaust system. Integration into the engine requires careful attention to alignment and secure mounting to prevent leaks and ensure efficient operation. Recommended procedures should be followed to maintain the integrity of the SCR system and ensure the injector functions as intended.

Troubleshooting and Maintenance

Common issues with the Cummins 5307918 Dosing Injector may include clogging or misalignment, which can affect its performance. Regular maintenance, such as cleaning and inspecting the injector, is recommended to ensure optimal operation. Following manufacturer guidelines for maintenance intervals and procedures can help prevent issues and extend the lifespan of the injector.

Environmental Impact

The use of dosing injectors like the Cummins 5307918 contributes to significant environmental benefits. By reducing NOx emissions, these injectors improve air quality and mitigate the environmental impact of commercial truck operations. The effective operation of the SCR system, facilitated by the dosing injector, is a key component in achieving cleaner emissions and supporting sustainable transportation practices.

Technological Advancements

Recent advancements in dosing injector technology have focused on improving precision, durability, and efficiency. Innovations in materials and control systems have enhanced the performance of dosing injectors, allowing for more accurate DEF dosing and better integration with engine management systems. These technological improvements contribute to the overall effectiveness of emissions control systems in commercial trucks.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a history of innovation and a commitment to sustainability, Cummins plays a role in advancing technology for cleaner and more efficient engines. The company’s product offerings are designed to meet the evolving needs of the automotive industry, with a focus on performance, reliability, and environmental responsibility.

Compatibility with Cummins Engines

The Dosing Injector 5307918 is compatible with a range of Cummins engines that share similar design and operational requirements. These engines often require precise fuel metering to maintain performance standards and comply with emission regulations. By ensuring that the Dosing Injector is correctly fitted, these engines can operate smoothly and efficiently, delivering the power and reliability that Cummins is known for.

Integration with Aftertreatment Systems

The Cummins 5307918 Dosing Injector is an integral component in the aftertreatment systems of modern engines, working in concert with several other components to ensure efficient and compliant emissions control.

Selective Catalytic Reduction (SCR) System

The dosing injector is a key player in the SCR system. It precisely injects Diesel Exhaust Fluid (DEF) into the exhaust stream upstream of the SCR catalyst. This injection facilitates the conversion of nitrogen oxides (NOx) into harmless nitrogen and water vapor.

Exhaust Gas Recirculation (EGR) System

While the EGR system reduces NOx by recirculating a portion of the exhaust gas back into the intake, the dosing injector ensures that any remaining NOx is effectively neutralized. This synergy between EGR and DEF injection enhances overall emissions reduction efficiency.

Diesel Particulate Filter (DPF)

The dosing injector also interacts with the DPF. By maintaining optimal exhaust temperatures through precise DEF dosing, it aids in the regeneration process of the DPF, ensuring that particulate matter is effectively burned off.

Communication with the Engine Control Unit (ECU)

The dosing injector communicates with the ECU, which monitors various parameters such as exhaust temperature, engine load, and emissions levels. The ECU sends signals to the dosing injector to adjust the amount of DEF injected, ensuring that the aftertreatment system operates within specified limits.

Feedback Loop with Sensors

Several sensors provide real-time data to the ECU, including:

- NOx Sensors: Located upstream and downstream of the SCR catalyst, these sensors measure the levels of nitrogen oxides before and after the DEF injection.

- Temperature Sensors: These monitor the exhaust temperature to ensure that the DEF is injected at optimal conditions for effective NOx reduction.

- Pressure Sensors: These ensure that the DEF is injected at the correct pressure, maintaining the efficiency of the aftertreatment process.

Role in Device Performance

The dosing injector’s role extends to enhancing the overall performance and reliability of the aftertreatment device. By ensuring that emissions are kept within regulatory limits, it helps in maintaining the device’s efficiency and longevity. This, in turn, contributes to the engine’s performance by allowing it to operate under optimal conditions without the risk of excessive emissions penalties.

Conclusion

The Cummins 5307918 Dosing Injector is a vital component in the emissions control system of commercial trucks. Its precise injection of DEF into the exhaust stream plays a significant role in reducing NOx emissions, ensuring compliance with environmental regulations, and maintaining engine performance. The injector’s integration with the SCR, EGR, and DPF systems, along with its communication with the ECU and feedback from sensors, underscores its importance in modern diesel engine technology. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part, contributing to cleaner air and sustainable transportation practices.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.