4329472

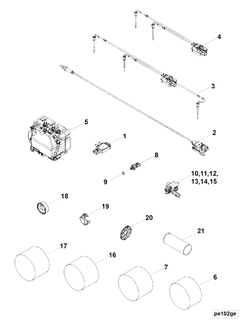

Doser Injector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction To Doser Injectors

A doser injector is a critical component in modern diesel engines, responsible for delivering precise amounts of fuel at the correct timing. This technology is pivotal in ensuring optimal engine performance, efficiency, and reduced emissions 1. The Cummins 4329472 doser injector is a prime example of advanced fuel injection systems designed to meet the rigorous demands of commercial truck operations.

How A Doser Injector Works

The doser injector operates by controlling the quantity and timing of fuel injection into the combustion chamber. It uses a combination of solenoids and a metering valve to regulate fuel flow. The doser injector receives signals from the engine control unit (ECU) to adjust the fuel delivery according to the engine’s operational needs 2. This precise control allows for better combustion, lower emissions, and enhanced fuel economy.

Purpose And Role Of The Cummins 4329472 Doser Injector

The Cummins 4329472 doser injector is engineered to provide reliable and efficient fuel delivery in heavy-duty truck engines. Its primary role is to ensure that the engine operates at peak performance by delivering the exact amount of fuel required for each combustion cycle. This precision helps in maximizing power output, reducing fuel consumption, and minimizing harmful emissions 3.

Importance In Truck Operations

In commercial truck operations, the doser injector is crucial for maintaining consistent engine performance, especially under heavy loads and varying driving conditions. It ensures that the engine runs smoothly and efficiently, which is vital for long-haul operations and fleet management. Reliable fuel delivery also contributes to the longevity of the engine by preventing wear and tear caused by improper combustion.

Troubleshooting Common Issues

Regular maintenance and timely troubleshooting are essential to keep the doser injector functioning optimally. Common issues include:

- Clogged Nozzles: Accumulation of deposits can obstruct the fuel flow. Regular cleaning and inspection can prevent this.

- Electrical Faults: Issues with the solenoids or wiring can disrupt the doser injector’s operation. Checking the electrical connections and replacing faulty components can resolve these problems.

- Leaking Seals: Worn-out seals can lead to fuel leaks. Inspecting and replacing seals as needed can maintain the integrity of the fuel system.

Maintenance Best Practices

To ensure the longevity and efficiency of the Cummins 4329472 doser injector, follow these maintenance practices:

- Regular Inspections: Conduct routine checks for signs of wear, leaks, and blockages.

- Cleaning: Periodically clean the injector nozzles to remove any deposits that may affect performance.

- Testing: Use diagnostic tools to test the doser injector’s operation and ensure it is responding correctly to ECU signals.

- Professional Servicing: Engage certified technicians for any major repairs or replacements to maintain the injector’s precision and reliability.

About Cummins

Cummins is a global leader in the design, manufacture, and distribution of diesel engines, diesel engine components, natural gas engines, and alternative energy solutions. With a strong commitment to innovation and quality, Cummins provides reliable and efficient products that meet the demanding needs of the commercial truck industry.

Conclusion

Understanding the functionality and importance of the Cummins 4329472 doser injector is crucial for engineers, mechanics, truck drivers, and fleet operators. Proper maintenance and troubleshooting can ensure that this vital component continues to deliver optimal performance, efficiency, and reliability in heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.