This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins Injector Remover, identified by part number 3825156, is a specialized tool designed for the maintenance and repair of diesel engines. Its primary role is to facilitate the safe and efficient removal and installation of fuel injectors, which are integral components in the operation of diesel engines. This tool is significant in ensuring that maintenance procedures are performed with precision, thereby contributing to the longevity and performance of diesel engines.

Purpose and Functionality

The Cummins Injector Remover plays a role in the operation and maintenance of diesel engines by providing a means to securely grip and extract fuel injectors without causing damage to the injector or the engine block. This tool is engineered to align with the specific contours and dimensions of Cummins fuel injectors, ensuring a snug fit that allows for the application of necessary force to dislodge injectors. Additionally, it aids in the installation process by guiding the injector into place, ensuring proper seating and alignment 1.

Key Features

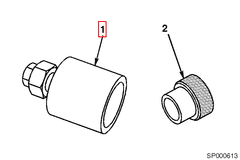

The Cummins Injector Remover is characterized by several design elements and materials that enhance its performance and durability. It is constructed from high-strength materials to withstand the forces involved in injector removal and installation. The tool features a precision-machined surface that matches the injector’s exterior, providing a secure grip. Its design also includes ergonomic handles for operator comfort and safety during use 2.

Benefits

Utilizing the Cummins Injector Remover offers several advantages in diesel engine maintenance. It improves efficiency by streamlining the injector removal and installation processes. The tool’s design minimizes the risk of damage to engine components during maintenance, preserving the integrity of the engine. Furthermore, by ensuring proper injector seating and alignment, it contributes to enhanced engine performance and reliability 3.

Operational Guidelines

To use the Cummins Injector Remover effectively, follow these guidelines: Begin by ensuring the engine is cool and the fuel system is depressurized for safety. Position the remover over the injector, aligning it with the injector’s exterior. Apply steady, even pressure to grip the injector securely. To remove the injector, use a rotational motion while applying upward force. For installation, reverse the process, ensuring the injector is properly aligned before seating it into the engine block. Always refer to the manufacturer’s instructions for specific procedures and safety precautions.

Troubleshooting and Maintenance

Common issues with the Cummins Injector Remover may include difficulty gripping the injector or damage to the tool’s surface. To address these, ensure the tool is correctly aligned with the injector and that it is free of debris. Regular inspection and cleaning of the tool can prevent buildup that may interfere with its function. For maintenance, store the remover in a dry place to prevent corrosion and check for any signs of wear or damage that may affect its performance.

Compatibility and Applications

The Cummins Injector Remover is designed for use with specific Cummins diesel engine models, catering to a range of commercial and industrial applications. Its applicability extends to various settings where diesel engines are prevalent, including transportation, construction, and power generation industries.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins provides a comprehensive range of products and services for diesel engine maintenance. The company’s dedication to excellence is reflected in its tools and components, which are designed to meet the demanding requirements of diesel engine maintenance and repair.

Role of Part 3825156 Injector Remover in Engine Systems

The Injector Remover, identified by part number 3825156, is an essential tool designed to facilitate the removal of fuel injectors from various engine systems. This tool is specifically engineered to interact with the fuel injector assembly, ensuring a secure grip and providing the necessary leverage to extract the injector without causing damage to surrounding components.

When working with engine systems, the Injector Remover is utilized in conjunction with several key components:

-

Fuel Injector Assembly: The primary component with which the Injector Remover interacts. It securely engages the injector, allowing for safe and efficient removal.

-

Cylinder Head: The Injector Remover operates in close proximity to the cylinder head, ensuring that the injector is extracted without compromising the integrity of the head or its gaskets.

-

Fuel Rail: Often connected to the injector, the fuel rail must be carefully managed during the removal process. The Injector Remover aids in disconnecting the injector from the fuel rail without causing leaks or damage.

-

O-Rings and Seals: These components are vital for maintaining fuel system integrity. The Injector Remover is designed to minimize disturbance to these seals during the removal process, preserving their condition for reinstallation.

-

Wiring Harness: Electrical connections to the injector must be detached before removal. The Injector Remover assists in this process by providing stability to the injector, making it easier to disconnect the wiring harness safely.

-

Engine Block: The overall engine block benefits from the precise extraction of injectors, as it reduces the risk of misalignment or damage during maintenance procedures.

By effectively engaging with these components, the Injector Remover ensures a smooth and damage-free removal process, contributing to the overall efficiency and safety of engine maintenance operations.

Conclusion

The Cummins Injector Remover (Part #3825156) is a vital tool in the maintenance and repair of diesel engines, offering efficiency, safety, and precision in the removal and installation of fuel injectors. Its design and functionality are tailored to the specific requirements of Cummins diesel engines, ensuring compatibility and effectiveness across a range of applications. Regular maintenance and proper use of this tool are essential for preserving engine integrity and performance.

-

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Watson, B. (2011). Mobile Equipment Hydraulics A Systems and Troubleshooting Approach. Cengage Learning.

↩ -

Lakshminarayanan, P. A., & Agarwal, A. K. (2019). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.