This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

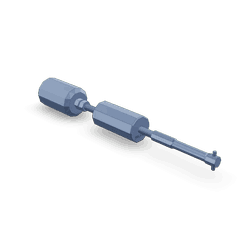

The Cummins Injector I and R Assembly, identified by part number 3824830, is a critical component in diesel engines, especially those used in commercial trucks. This assembly is integral to the fuel injection system, ensuring efficient and precise fuel delivery to the engine cylinders. Its application in commercial trucks highlights its importance in maintaining engine performance, fuel efficiency, and emissions control.

Basic Concepts

Fuel injection systems in diesel engines are designed to deliver fuel into the combustion chamber at high pressure and precise timing. The Injector I and R Assembly plays a specific role in this system by controlling the injection of fuel into the engine cylinders. It consists of components that work together to atomize fuel, ensuring it mixes effectively with air for combustion. Understanding these fundamental concepts is key to appreciating the role of the Injector I and R Assembly in diesel engine operation 1.

Purpose and Function

The Cummins Injector I and R Assembly is designed to facilitate the injection of fuel into the diesel engine’s combustion chamber. Its purpose is to deliver fuel at the right pressure and timing, which is crucial for efficient combustion. This assembly contributes to fuel efficiency by ensuring that fuel is atomized properly, leading to more complete combustion. It also plays a role in enhancing power output and controlling emissions by optimizing the fuel injection process 2.

Key Features

The Cummins Injector I and R Assembly is characterized by its robust design and construction, utilizing high-quality materials to withstand the harsh conditions within a diesel engine. It incorporates technological advancements such as precision machining and electronic control systems to ensure accurate fuel delivery. Unique characteristics of this assembly include its ability to operate under high pressure and its integration with electronic control units for optimized performance 3.

Benefits

The benefits of the Cummins Injector I and R Assembly include improved fuel atomization, which leads to more efficient combustion and better fuel economy. Precise fuel delivery ensures that the engine operates at optimal efficiency, enhancing power output. Additionally, the assembly contributes to emissions control by ensuring that fuel is burned more cleanly. These benefits translate into real-world advantages for truck operators, such as reduced fuel consumption, increased engine performance, and compliance with emissions regulations 4.

Troubleshooting and Maintenance

Common issues with the Cummins Injector I and R Assembly may include clogged injectors, leaks, or electronic control malfunctions. Troubleshooting steps involve checking for proper fuel pressure, inspecting injector tips for clogging, and ensuring the electronic control system is functioning correctly. Routine maintenance practices include regular cleaning of injectors, checking for leaks, and updating the electronic control software as needed. These practices help ensure the optimal performance and longevity of the injector assembly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines. With a history spanning over a century, Cummins has established a reputation for innovation and quality in the automotive industry. The company’s commitment to advancing diesel engine technology is evident in its product offerings, which are designed to meet the demanding requirements of commercial and industrial applications.

Conclusion

The Cummins Injector I and R Assembly (part #3824830) is a vital component in diesel engines, particularly in commercial trucks. Its role in ensuring efficient and precise fuel delivery contributes significantly to engine performance, fuel efficiency, and emissions control. Understanding its purpose, features, and benefits, along with proper maintenance practices, is essential for maximizing the performance and longevity of this Cummins part.

-

Lakshminarayanan, P A, and Yogesh V Aghav. Modelling Diesel Combustion. Springer Science, 2010.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Pulkrabek, Willard W. Engineering Fundamentals of the Internal Combustion Engine. Pearson Education, 2014.

↩ -

Wright, Gus. Fundamentals of Medium-Heavy Duty Diesel Engines. Jones & Bartlett Learning, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.